Abstract

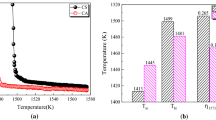

To moderate the erosion in a slag-line zone and extend the service life of a submerged entry nozzle during continuous casting of high-Mn and high-Al steel, the current study developed a low-reaction CaO-Al2O3-based slag with lower SiO2 and higher Al2O3 contents than that of conventional CaO-SiO2-based slag. The static sessile drop technique and dynamic rotating cylinder method were utilized to investigate the erosion behavior of ZrO2-graphite refractory by the above slags. The main results indicated that silicate-based slag could wet the ZrO2-graphite substrate completely, while the aluminate-based slag spread rapidly in the first 20 minutes, and then a slag drop with an unchanged profile formed on the substrate. The equilibrium contact angles with the substrate at 1623 K were 0 and 79 deg for the CaO-SiO2 and CaO-Al2O3 based slags, respectively. The comparison of the influences of the rotating speed and the temperature revealed that the decrease of erosion rate could be realized by the developed slag. An examination of ZrO2-saturation limit also indicated that the low-reaction slag could dissolve much more ZrO2 oxidation, accompanied by a less-negative effect on the viscosity of the molten slag.

Similar content being viewed by others

References

[1] L.M. Aksel’rod: Refract. Ind. Ceram., 1996, vol. 37, pp. 207-10.

[2] Y. Nakamura, T. Ando, K. Kurata, and M. Ikeda: Trans. ISIJ, 1986, vol. 26, pp. 1052-58.

K.C. Mills, Carl-Åke Däcker: The Casting Powders Book, Springer Nature, 2017.

[4] A.F. Dick, X. Yu, R.J. Pomfret, and K.S. Coley: ISIJ Int., 1997, vol. 37, pp. 102-08.

[5] Y. Hemberger, C. Berthold, and K.G. Nickel: J. Eur. Ceram. Soc., 2012, vol. 32, pp. 2859-66.

[6] H. Kyoden and Y. Namba: Taikabutsu Overseas, 1984, vol. 36, pp. 218.

[8] M. Chen, C.Y. Lu, J.K. Yu: J. Eur. Ceram. Soc., 2007, vol. 27, pp. 4633-38.

[9] J.H. Park: Calphad, 2007, vol. 31, pp. 149-54.

[10] J. Szczerba, Z. Pędzich: Ceram. Int., 2010, vol.36, pp. 535-47.

[11] J.L. Klug, M.M. Pereira, E.L. Nohara, S.L. Freitas, G.T. Ferreira, and D. Jung: Ironmaking Steelmaking, 2016, vol. 43, pp. 559-63.

[12] F. Hauck and J. Potschke: Archiv Fur Das Eisenhuttenwesen, 1982, vol. 53, pp. 133-38.

[13] T.M. Ye, W.D. Yi, W.J. Xiao, G.P. Wang, and Y.H. Pan: J. Iron Steel Res. Int., 2008, vol. 15, pp. 669-74.

[14] J. Zhang, C.Q. Zhang, L. Wang, M.R. Han, and W.S. Hwang: Metallurgist, 2017, vol. 60, pp. 916-22.

[15] A.H. Bui, S.C. Park, I.S. Chung, and H.G. Lee: Met. Mater. Int., 2006, vol. 12, pp. 435-40.

[16] F. Cirilli, A.D. Donato, U. Martini, P. Miceli, P. Guillo, J. Simoes, and Y.J. Song: Metall. Ital., 2008, vol. 100, pp. 43-50.

[17] M.O. Suk and J.H. Park: J. Am. Ceram. Soc., 2009, vol. 92, pp. 717-23.

[18] A. Kumar, R. Khanna, J. Spink, and V. Sahajwalla: Steel Res. Int., 2014, vol. 85, pp. 1185-93.

H. Harmuth, V. Kircher, N. Kolbl, M. Antczak, and G. Xia: Proc. Unified Int. Tech. Conf. Refract., 2013, pp. 801–06.

[20] W.L. Wang, B.X. Lu, and D. Xiao: Metall. Mater. Trans. B, 2016, vol. 47, pp. 384-89.

[21] G.H. Kim and I. Sohn: Metall. Mater. Trans. B, 2016, vol. 47, pp. 1773-84.

X.B. Zhang, Y. Ren, L.F. Zhang, and W. Yang: Metall. Mater. Trans. B, 2018, https://doi.org/10.1007/s11663-018-1366-9.

G. Skoczylas: 79th Steelmak. Conf., 1996, pp. 269–75.

[24] Q. Liu, G.H. Wen, J. Li, X. Fu, P. Tang, and W. Li: Ironmaking Steelmaking, 2014, vol. 41, pp. 292-97.

[25] J.W. Cho, K. Blazek, M. Frazee, H.B. Yin, J.H. Park, and S.W. Moon: ISIJ Int., 2013, vol. 53, pp. 62-70.

[26] G.H. Kim and I. Sohn: Metall. Mater. Trans. B, 2014, vol. 45, pp. 86-95.

[27] H. Zhao, W.L. Wang, L.J. Zhou, B.X. Lu, and Y.B. Kang: Metall. Mater. Trans. B, 2014, vol. 45, pp. 1510-19.

[28] T. Wu, Q. Wang, S.P. He, J.F. Xu, X. Long, and Y.J. Lu: Steel Res. Int., 2012, vol. 83, pp. 1194-202.

[29] K.C. Mills: ISIJ Int., 2016, vol. 56, pp. 1-13.

[30] X. Long, S.P. He, Q. Wang, and P.C. Pistorius: Metall. Mater. Trans. B, 2017, vol. 48, pp. 1652-58.

L.L. Zhu, Q. Wang, Q.Q. Wang, S.D. Zhang, and S.P. He: J. Am. Ceram. Soc., 2018, https://doi.org/10.1111/jace.16085.

[32] S.D. Zhang, Q.Q. Wang, S.P. He, and Q. Wang: Metall. Mater. Trans. B, 2018, vol. 49, pp. 2038-49.

[33] K. Mukai, H. Iwasaki, T. Eguchi, S. Iizuka, J.M. Toguri: Taikabutsu (Refractories), 1990, vol.42, pp. 710-19.

P. Shen, L.F. Zhang, Yi Wang, S. Sridhar, and Q.Q. Wang: Ceram. Int., 2016, vol. 42, pp. 16040-48.

[35] M.R. Yang, X.W. Lv, R.R. Wei, and C.G. Bai: Metall. Mater. Trans. B, 2018, vol. 49, pp. 2667-80.

[36] M.R. Yang, X.W. Lv, R.R. Wei, J. Xu, and C.G. Bai: Metall. Mater. Trans. B, 2018, vol. 49, pp. 1331-45.

A.R. Cooper: Proc. Educ. Symp. Refract. Sagging Environ. Ceram. Eng. Sci. Proc., 1981, pp. 1063–89.

A.W. Cramb and I. Jimbo: Trans. ISS, 1989, pp. 43–55.

[39] T. Imaoka and Y. Iwamoto: Shinagawa Technical Report, 2012, vol. 55, pp. 21-30.

[40] C.C. Miller: Proc. R. Soc. London. Ser. A, 1924, vol. 106, pp. 724-29.

[41] P. Rocabois, J. Lehmann, H. Gaye, and J.N. Pontoire: J. Non-Cryst. Solids, 2001, vol. 282, pp. 98-109.

[42] Z.T. Zhang, G.H. Wen, and Y.Y. Zhang: Int. J. Miner. Metall. Mater., 2011, vol. 18, pp. 150-58.

R.J. Phillips, W.F. Salem, W.R. Emling, and H.D. Baker: 73rd Steelmak. Conf. Proc., 1990, pp. 247–51.

D.W. Bruce and N.S. Hunter: Proc. 2nd Eur. Conf. Contin. Cast., 1994, p. 156.

[45] T. Mukongo, P.C. Pistorius, and A.M. Garbers-Craig: Ironmaking Steelmaking, 2004, vol. 31, pp. 135-43.

[46] Z. Wang, Q.F. Shu, H.M. Hou, and K.C. Chou: Ironmaking Steelmaking, 2012, vol. 39, pp. 210-15.

[47] A.B. Fox, K.C. Mills, D. Lever, C. Bezerra, C. Valadares, I. Unamuno, J.J. Laraudogoitia, and J. Gisby: ISIJ Int., 2005, vol. 45, pp. 1051-58.

[48] H. Hashimoto, T. Watanabe, and K. Nagata: CAMP-ISIJ, 2004, vol. 17, pp. 849.

Acknowledgments

The authors are grateful for the support from the National Natural Science Foundation of China (Grant Nos. 51804057, U1660204, and 51874057), and the Fundamental Research Funds for the Central Universities in China (Grant No. 2018CDXYCL0018).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted October 8, 2018.

Rights and permissions

About this article

Cite this article

Zhang, S., Yuan, H., Gan, M. et al. Wetting and Erosion of ZrO2-Graphite Refractory by CaO-SiO2 and CaO-Al2O3-Based Mold Slags for Submerged Entry Nozzle. Metall Mater Trans B 50, 1407–1416 (2019). https://doi.org/10.1007/s11663-019-01541-z

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-019-01541-z