Abstract

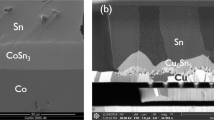

Transient Liquid Phase (TPL) bounding of Sn foil sandwiched between two Cu foils involves, in the temperature range above the melting point of Sn (232 °C) and below 350 °C, the formation and the growth of two intermetallic compounds (IMCs) Cu6Sn5 and Cu3Sn and mostly unintended micro-pores. The present study aims to analyze the mechanism of void development during the soldering process through an experimental and modeling approach of diffusion-controlled IMC transformation. This modeling couples the diffusion process and the interface motion with the volume shrinkage induced by the difference of partial molar volumes of atoms between each phase. We also consider two types of inter-diffusion transports: (i) inter-diffusion based on the exchange of Cu and Sn atoms and (ii) inter-diffusion of Sn atoms with vacancies allowing Kirkendall void formation. The simulations of IMC growth performed correspond to a sequence of planar phase layers, where the distinctive scallop morphology of the Cu6Sn5 layer is described through an analytical function allowing to quantify the grain boundary diffusion pathway. We take into account of the volume diffusion mechanism for Cu3Sn intermetallic. For Cu6Sn5 intermetallic two mechanisms are considered, volume diffusion and grain boundary diffusion, limited by grain growth. The simulations of IMC growth kinetics, for different transport scenarios, are compared to the experimental evolving morphologies to determine the most likely mechanism of micro-void formation.

Similar content being viewed by others

References

P. Beckedahl, Power Electron. Europe, 2011, 5, 23 http://www.power-mag.com/pdf/issuearchive/47.pdf

J.F. Li, P.A. Agyakwa, C.M. Johnson, Acta Mater., 2011, 59, 1198-211

T.B. Massalski, Binary alloy phase diagrams. (ASM Int. Materials Park, Ohio, 1990), pp. 1481-83

S. Fürtauer, D. Li, D. Cupid, H. Flandorfer, Intermetallics, 2013, 34, 142-47

C. Flötgen, M. Pawlak, E. Pabo, Microsyst. Technol., 2014, 20, 653-62

W.-L. Chui, C.-M. Liu, Y.-S. Haung, C. Chen, Appl. Phys. Lett., 2014, 104, 171905

D. Ma, W.D. Wang, S.K. Lahiri, J. Appl. Phys., 2002, 91, 3312-17

N.S. Bosco, F.W. Zok, Acta Mater., 2004, 52, 2965-72

M.S. Park, R. Arróyave, Acta Mater., 2012, 60, 923-34

M.S. Park, S.L. Gibbons, R. Arróyave, Acta Mater., 2012, 60, 6278-6287

M.S. Park, S.L. Gibbons, R. Arróyave, Microelectron. Reliab., 2014, 54, 1401-11

H. Shao, A. Wu, Y. Bao, Y. Zhao, G. Zou, Mater. Sc. Eng. A, 2017, 680, 221-231

H.Y. Chuang, T.L. Yang, M.S. Kuo, Y.J. Chen, J.J. Yu, C.C. Li, C.R. Kao, IEEE Trans. Device Mater. Reliab., 2012, 12, 233-240

Z. Mei, A.J. Sunwoo, J.W. Morris, Metall. Trans. A, 1992, 23, 857-864

E. Kirkendall, Trans. AIME, 1947, 147, 104-110

F. Gao, J. Qu, Mater. Lett., 2012, 73, 92–94

M. O. G. Vakanas, N. Moelans, M. Kajihara, W. Zhang, Microelectron. Eng., 2014, 120, 133-137

A. Paul, C. Ghosh, W.J. Boettinger, Metall. Mater. Trans. A, 2011, 42A, 952-63

K.N. Tu, R.D. Thompson, Acta Metall.,1982, 30, 947-952

S. Kumar, C.A. Handwerker, M.A. Dayananda, J. Phase Equilib. Diff., 2011, 32, 309-319

D.S. Duvall, W.A. Owczarski, D.F. Paulonis, Weld. J., 1974, 53, 203-214

L. Bernstein, J. Electrochem. Soc., 1966, 113, 1282-1288

I. Tuah-Poku, M. Dollar, T.B. Massalski, Metall. Trans. A, 1988, 19A, 675-686

G.O. Cook, C.D. Sorensen, J. Mater. Sc., 2011, 46, 5305-5323

M. Schaefer, R.A. Fournelle, J. Liang, J. Electron. Mater., 1998, 27, 1167-1176

B. Dimcic, R. Labie, J. De Messemaeker, K. Vanstreels, K. Croes, B. Verlinden, I. De Wolf, Microelectron. Reliab., 2012, 52, 1971-1974

K.L. Erickson, P.L. Hopkins, P.T. Vianco, J. Electron. Mater., 1994, 23, 729-734

P. Villars, L.D. Calvert, Pearson’s handbook of Crystallographic Data for intermetallic Phases (ASM, Metals Park, Ohio, 1985), pp. 2030

B. Alchagirov, A.M. Chochaeva, High Temp., 2000, 38, 44-48

M. Raessi, J. Mostaghimi, Numer. Heat Tr. Part B, 2005, 47, 507-531

J.A. Cahill, A.D. Kirshenbaum, J. Phys. Chem., 1962, 66, 1080-82

M. Onishi, H. Fujibuchi, Trans. JIM, 1975, 16, 539-547

J.F. Li, P.A. Agyakwa, C.M. Johnson, Intermetallics, 2013, 40, 50-59

K. Hoshino, Y. Iijima, K. Hirano, Trans JIM, 1980, 21, 674-682

C.H. Ma, R.A. Swalin, Acta Metall., 1960, 8, 388-395

D. Prokoshkina, V.A. Esin, G. Wilde, S.V. Divinski, Acta Mater., 2013, 61, 5188-5197

Y. Zhou, T.H. North, Acta Metall. Mater., 1994, 42, 1025-1029

R. An, Y. Tian, R. Zhang, J. Mater. Sci.: Mater. Electron., 2015, 26, 2674-81

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted January 26, 2018.

Rights and permissions

About this article

Cite this article

Bordère, S., Feuillet, E., Diot, JL. et al. Understanding of Void Formation in Cu/Sn-Sn/Cu System During Transient Liquid Phase Bonding Process Through Diffusion Modeling. Metall Mater Trans B 49, 3343–3356 (2018). https://doi.org/10.1007/s11663-018-1391-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-018-1391-8