Abstract

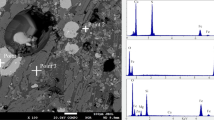

Copper slag, a by-product of copper pyrometallurgy, inevitably contains a certain amount of copper. Oxygen-enriched smelting technologies increase the copper content in slag indirectly because of the production of higher-grade matte. The effect of iron phase evolution on the copper content in slag during the slag cleaning process in an electric furnace was investigated using the method of combining theory with experiments. Based on the analysis, the main factors that impede the separation of slag and copper/matte were determined. Subsequently, the properties of slag were analyzed after decreasing the magnetite content within the slag. The experimental results showed that decreases in magnetite content were beneficial for the separation of copper and slag because of the decrease of slag viscosity. Nevertheless, Cu-Fe alloys formed when magnetite was completely reduced to metallic iron, and the foaming slag was formed at 1250 °C. Furthermore, the distribution of copper in the reduced slags was studied in detail.

Similar content being viewed by others

References

1. I.F.F. Neto, C. A. Sousa, M.S.C.A. Brito, A. M. Futuro, and H.M.V.M. Soares, Sep. Purif. Technol, 2016, vol. 164, pp. 19–27.

2. B. Das, B.K. Mishra, S. Angadi, S.K. Pradhan, S. Prakash, and J. Mohanty, Waste Management & Research the Journal of the International Solid Wastes & Public Cleansing Association Iswa, 2010, vol. 28, pp. 561-567.

M.E. Schlesinger, M.J. King, K.C. Sole, and W.G. Davenport, Extractive Metallurgy of Copper 5th ed, Elsevier, Oxford, 2011.

4. R. Sridhar, J.M. Toguri, and S. Simeonov, Metall. Mater. Trans. B, 1997, vol. 28B, pp. 191-200.

5. R. Sharma, and R.A. Khan, J. Clean. Prod, 2017, vol. 151, pp. 179-192.

6. A. Rusen, A.Geveci, Y. A. Topkaya, and B. Derin, JOM, 2016, vol. 68, pp.2323-2331.

Jones, M.J., Advances in extractive metallurgy and refining, IMM, London, 1972.

8. P. Spira, N. J. Themelis, JOM. 1969, vol. 21, pp. 35-42.

9. J.C. Yannopoulos, Can. Metall. Q., 1971, vol. 10, pp. 291-307.

10. J.M. Toguri, N.J. Themelis, and P.H. Jennings, Can. Metall. Q., 1964, vol. 3, pp. 197-220.

M.E. Schlesinger, M.J. King, A.W. Davenport, and K.C. Sole, Extractive Metallurgy of Copper, 5th ed. Elsevier, New York, 2011.

12. H. Jalkanen, J. Vehviläinen, and J. Poijärvi, Scand. J. Metall., 2003, vol. 32, pp. 65-70.

13. N. Cardona, P. Coursol, P. J. Mackey, and R. Parra, Can. Metall. Q., 2011, vol. 50, pp. 318-29.

14. M. Kucharski, Archiwum Hutnictwa, 1987, vol. 32, pp. 307-23.

15. H.P. Rajcevic and W.R. Opie, JOM, 1982, vol. 34, pp. 54-56.

A. Moreno, G. Sánchez, A. Warczok, and G. Riveros, Proc. Conf. Copper 2003, London, Metallurgical Societ of CIM, 2003, vol. IV, pp. 475–92.

17. A. Warczok, G. Riveros, P. Echeverrã, C.M. Díaz, H. Schwarze and G. Sánchez, Can. Metall. Q., 2013, vol. 41, pp. 465-473.

V. Montenegro, T. Fujisawa, A. Warczok, and G. Riveros, Metallurgical and Materials Processing: Principles and Technologies, 2003, High-Temperature Metal Production, vol 2, pp. 199–09.

A. Warczok, G. Riveros, and V. Montenegro, Proc. 5th Int. Conf. Copper 2003, Santiago, Chile, November 30–December 3, 2003, pp. 1–17.

20. A. Warczok, T. A. Utigard, Metall. Mater. Trans. B., 1995, vol. 26, pp. 1165-1173.

21. M. S. Bafghi, ISIJ Int., 2007, vol. 32, pp. 1084-1090.

22. A. Mitrašinović, JOM, 2017, vol. 69, pp. 1-6.

23. A. Warczok, T. A. Utigard, Can. Metall. Q., 2013, vol. 37, pp. 27-39.

24. J.H. Heo, Y, Chung, and J.H. Park, J. Clean. Prod., 2016, vol. 137, pp. 777-787.

A.A. Lykasov, G.M. Ryss, D.G. Sharafutdinov, and A.Y. Pogodin, Izvestiya Vysshikh Uchebnykh Zavedenij Chernaya Metall. 2016, vol. 59, pp. 597-607.

26. D. Busolic, F. Parada, R. Parra, M. Sanchez, J. Palacios, and M. Hino, Miner. Process. Extr. Metall., 2011, vol. 120, pp. 32-36.

27. H.F. Yang, L.L. Jing, and C.G. Dang, Chin. J. Nonferrous. Met., 2011, vol. 21, pp. 1165-1170.

28. R.W. Ruddle, The physical chemistry of copper smelting, IMM, London, 1953.

29. C.P Liu, Nonferrous Metals: Extractive Metallurgy, 1975, vol. 8, pp. 36-45. (In Chinese)

L. Bodnar, S. Cempa, K. Tomasek, and L. Bobok, Chem. Pap. 1978, vol. 32(6), pp. 798–809.

31. J.O. Bockris, and D.C. Lowe, Proc. R. Soc. A., 1954, vol. 226, pp. 423-435.

32. G.H. Kaiura, J.M. Toguri, and G. Marchant, Can. Metall. Q., 2013, vol. 16, pp. 156-160.

P. Taskinen, K. Seppã¤Lã¤, J. Laulumaa, and J. Poijã¤Rvi, Min. Proc. Ext. Met., 1997, vol. 110, pp. 94–100.

34. J. Matousek, JOM, 2012, vol. 64, pp. 1314-1320.

35. S.W. Ip, and J.M. Toguri, Metall. Trans. B., 1992, vol. 23, pp. 303-311.

36. P.K. Iwamasa, and R.J. Fruehan, ISIJ Int., 1996, vol. 36, pp. 1319-1327.

37. N. Cardona, P. Coursol, J. Vargas, and R. Parra, Can. Metall. Q., 2013, vol. 50, pp. 330-340.

38. S.A. Degterov, and A.D. Pelton, Metall. Mater. Trans. B., 1999, vol. 30B, pp. 1033-1044.

39. D.C. Lynch, S. Akagi, and W.G. Davenport, Metall. Trans. B., 1991, vol. 22, pp. 677-688.

Acknowledgments

This work was supported by the National Natural Science Foundation of China (U1602272 and 51664039) and the Analysis and Testing Foundation of Kunming University of Science and Technology (2017P20161102004).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Manuscript submitted March 20, 2018.

Rights and permissions

About this article

Cite this article

Zhou, S., Wei, Y., Li, B. et al. Effect of Iron Phase Evolution on Copper Separation from Slag Via Coal-Based Reduction. Metall Mater Trans B 49, 3086–3096 (2018). https://doi.org/10.1007/s11663-018-1379-4

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-018-1379-4