Abstract

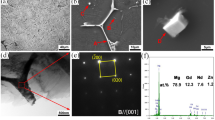

In the present work, two-step heat treatments with preheating at different temperatures (175 °C, 250 °C, and 330 °C) as the first step followed by the peak precipitation treatment (375 °C/48 h) as the second step were performed in Al-Mn-Mg 3004 alloys to study their effects on the formation of dispersoids and the evolution of the elevated-temperature strength and creep resistance. During the two-step heat treatments, the microhardness is gradually increased with increasing time to a plateau after 24 hours when first treated at 250 °C and 330 °C, while there is a minor decrease with time when first treated at 175 °C. Results show that both the yield strength (YS) and creep resistance at 300 °C reach the peak values after the two-step treatment of 250 °C/24 h + 375 °C/48 h. The formation of dispersoids is greatly related to the type and size of pre-existing Mg2Si precipitated during the preheating treatments. It was found that coarse rodlike β′-Mg2Si strongly promotes the nucleation of dispersoids, while fine needle like β″-Mg2Si has less influence. Under optimized two-step heat treatment and modified alloying elements, the YS at 300 °C can reach as high as 97 MPa with the minimum creep rate of 2.2 × 10−9 s−1 at 300 °C in Al-Mn-Mg 3004 alloys, enabling them as one of the most promising candidates in lightweight aluminum alloys for elevated-temperature applications.

Similar content being viewed by others

References

Y.J. Li, A.M.F. Muggerud, A. Olsen, and T. Furu: Acta Mater., 2012, vol. 60, pp. 1004–14.

K. Liu and X.G. Chen: Mater. Des., 2015, vol. 84, pp. 340–50.

K. Liu and X.G. Chen: Metall. Mater. Trans. B, 2015, vol. 47B, pp. 3291–3300.

Y.J. Li and L. Arnberg: Acta Mater., 2003, vol. 51, pp. 3415–28.

R. Kamat: JOM, 1996, vol. 48, pp. 34–38.

Q. Du, W.J. Poole, M.A. Wells, and N.C. Parson: Acta Mater., 2013, vol. 61, pp. 4961–73.

K. Liu, H. Ma, and X.G. Chen: J. Alloys Compd., 2017, vol. 694, pp. 354–65.

K. Liu and X.-G. Chen: J. Mater. Res., 2017, vol. 32, pp. 2585–93.

K. Liu, A.M. Nabawy, and X.-G. Chen: Trans. Nonferrous Met. Soc. China, 2017, vol. 27, pp. 771–78.

H.-W. Huang and B.-L. Ou: Mater. Des., 2009, vol. 30, pp. 2685–92.

A.M.F. Muggerud, E.A. Mørtsell, Y. Li, and R. Holmestad: Mater. Sci. Eng., A, 2013, vol. 567, pp. 21–28.

Y. Li and L. Arnberg (2013) Essential Readings in Light Metal. Wiley, Hoboken, NJ, pp. 1021–27

K. Liu and X.G. Chen: Mater. Sci. Eng. A, 2017, vol. 697, pp. 141–48.

Y.-L. Deng, Y.-Y. Zhang, L. Wan, A. Zhu, and X.-M. Zhang: Metall. Mater. Trans. A, 2013, vol. 44A, pp. 2470–77.

Z. Guo, G. Zhao, and X.G. Chen: Mater. Charact., 2015, vol. 102, pp. 122–30.

Z. Jia, G. Hu, B. Forbord, and J. K. Solberg: Mater. Sci. Eng. A, 2008, vols. 483–484, pp. 195–98.

X.-Y. Lü, E.-J. Guo, P. Rometsch, and L.-J. Wang: Trans. Nonferrous Met. Soc. China, 2012, vol. 22, pp. 2645–51.

J.D. Robson: Mater. Sci. Eng. A, 2002, vol. 338, pp. 219–29.

P. X. Liu, Y. Liu, and R. Xu: Trans. Nonferrous Met. Soc. China, 2014, vol. 24, pp. 2443–51.

E.R. Weibel and H. Elias: Quantitative Methods in Morphology, Springer-Verlag, Berlin, 1967.

A.R. Farkoosh, X. Grant Chen, and M. Pekguleryuz: Mater. Sci. Eng., A, 2015, vol. 620, pp. 181–89.

L. Lodgaard and N. Ryum: Mater. Sci. Eng., A, 2000, vol. 283, pp. 144–52.

J. Osten, B. Milkereit, C. Schick, and O. Kessler: Materials, 2015, vol. 8, pp. 2830–48.

Y. Ohmori, L.C. Doan, and K. Nakai: Mater. Trans., 2002, vol. 43, pp. 246–55.

A. Gaber, M.A. Gaffar, M.S. Mostafa, and A.F. Abo Zeid: Mater. Sci. Technol., 2006, vol. 22, pp. 1483–88.

L.C. Doan, K. Nakai, Y. Matsuura, S. Kobayashi, et al.: Mater. Trans., 2002, vol. 43, pp. 1371–80.

Y. Birol: Trans. Nonferrous Met. Soc. China, 2013, vol. 23, pp. 1875–81.

J.G. Kaufman: Properties of Aluminum Alloys: Tensile, Creep, and Fatigue Data at High and Low Temperatures; Aluminum Association, Washington, DC, 1999.

C. Booth-Morrison, D.C. Dunand, and D.N. Seidman: Acta Mater., 2011, vol. 59, pp. 7029–42.

K.E. Knipling, D.C. Dunand, and D.N. Seidman: Acta Mater., 2008, vol. 56, pp. 114–27.

X.M. Chen, Y.C. Lin, M.S. Chen, H.B. Li, D.X. Wen, J.L. Zhang, et al.: Mater. Des., 2015, vol. 77, pp. 41–49.

T. Wang, C. Wang, W. Sun, X. Qin, J. Guo, and L. Zhou: Mater. Des., 2014, vol. 62, pp. 225–32.

Acknowledgments

The authors acknowledge the financial support of the Natural Sciences and Engineering Research Council of Canada (NSERC) and Rio Tinto Aluminum through the NSERC Industry Research Chair in the Metallurgy of Aluminum Transformation at the University of Quebec at Chicoutimi.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted August 16, 2017

Rights and permissions

About this article

Cite this article

Liu, K., Ma, H. & Chen, X.G. Improving the Elevated-Temperature Properties by Two-Step Heat Treatments in Al-Mn-Mg 3004 Alloys. Metall Mater Trans B 49, 1588–1596 (2018). https://doi.org/10.1007/s11663-018-1268-x

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-018-1268-x