Abstract

Slag refining is one of few metallurgical methods for removal of boron from silicon. It is important to know the thermodynamic properties of boron in slags to understand the refining process. The relation of the distribution coefficient of boron to the activity of silica, partial pressure of oxygen, and capacity of slags for boron oxide was investigated. The link between these parameters explains why the distribution coefficient of boron does not change much with changing slag composition. In addition, the thermodynamic properties of dilute boron oxide in CaO-MgO-Al2O3-SiO2 slags was determined. The ratio of the activity coefficient of boron oxide and silica was found to be the most important parameter for understanding changes in the distribution coefficient of boron for different slags. Finally, the relation between the activity coefficient of boron oxide and slag structure was investigated. It was found that the structure can explain how the distribution coefficient of boron changes depending on slag composition.

Similar content being viewed by others

Introduction

The thermodynamic properties of boron in slag and silicon have been in focus for some time due to the possibility of removing boron from silicon by slag refining. Slag refining is one of the few metallurgical refining methods that can be used to remove boron from silicon. This is a part of a method for refining silicon directly to solar grade using metallurgical techniques. Lower cost, less energy use, and a reduced carbon footprint are the potential benefits of using a purely metallurgical refining process instead of a chemical purification method. The conventional technique for making solar grade silicon is a chemical vapor deposition method using chlorosilane or silane.

Knowing the thermodynamic properties of boron in slags is important for understanding the refining process. Slag refining for boron removal is an oxidation process where boron dissolved in silicon is oxidized at the slag-silicon interface and absorbed into the slag through the reaction

The stability of boron oxide is similar to that of silicon dioxide.[1] In addition, there is no strong interaction between boron oxide and silicon dioxide in slags,[2] or between boron and silicon in metal.[3] Altogether, this means that boron does not have a strong affinity for either slag or silicon, as will be seen from the experimental data discussed later in this article.

The ability of a slag for extracting boron from silicon can be expressed by the distribution coefficient of boron, \( L_{\text{B}} \), which is given by

where w is the weight fraction, x is the mole fraction, and \( k_{w \to x} \) is the conversion factor going from weight fraction to mole fraction.

The concentration of boron in the system is at parts per million level in this work. Since the interaction between boron and silicon is relatively weak in both metallic and oxide form, the assumption in this work is that boron behaves as a Henrian solute in both slag and silicon. This may not be true regarding interaction of boron with other components in the slag, but Henrian behavior of boron was still assumed because of the limited thermodynamic data available to make any other assumption.

If this assumption is not valid, the activity coefficient of boron oxide in slag is a regular activity coefficient rather than a Henrian activity coefficient. The measurements are, however, done at low boron contents. Therefore, a possible deviation from Henrian solute behavior is expected to be relatively small.

Hence, the equilibrium for oxidation of boron is given by

where \( \gamma_{{{\text{BO}}_{1.5} }}^{\text{o}} \) is the Henrian activity coefficient of boron oxide in slag and \( \gamma_{\text{B}}^{\text{o}} \) is the Henrian activity coefficient of boron in silicon. For SiO2, β-cristobalite was used as the standard state, while the liquid standard state was used for the other components.

The activity of SiO2 can be found in the literature or it can be calculated from thermodynamic databases. The activity of silicon is assumed to follow Raoult’s law since the concentration of other impurities is relatively low. In this work the mole fraction of silicon was determined by measuring the content of other impurities in silicon.

The equation for the equilibrium constant can be rearranged into an expression for the Henrian activity coefficient of boron oxide:

Alternatively, the distribution of boron between silicon and slag can be expressed in terms of the activity coefficient of boron in silicon and boron oxide in the slag by rearranging this equation.

The Henrian activity coefficient of boron oxide in slags is mostly unknown. The only known estimates are deduced from experimental data for the distribution coefficient of boron, see References 4,5,6, through 7. In addition, there are limited data for the Henrian activity coefficient of boron in silicon. Therefore, different thermodynamic relations have been found depending on the experimental results.

Noguchi et al.[4] determined the Henrian activity coefficient of boron in silicon using boron nitride (BN) and a controlled partial pressure of nitrogen. They used this to calculate the activity coefficient of boron oxide in slags using results from a previous study.[5] From this, they found the activity coefficient to decrease monotonically with increasing basicity of the slag.

The Henrian activity coefficient of boron in silicon was later revised by Yoshikawa and Morita.[8] Yoshikawa and Morita determined the Henrian activity coefficient of boron in silicon by having silicon saturated with both Si3N4 and BN. The results were found to be in agreement with Inoue et al.[9] They also re-evaluated the results from Noguchi et al. based on the assumption that Si3N4 had also been present in those experiments. The re-evaluated activity coefficient was in good agreement with their own measurements and the work by Inoue et al. The Henrian activity coefficient was determined to be

in the range from 1693 K to 1923 K. This value was also employed in the present work.Footnote 1

An estimate of the Henrian activity coefficient can also be derived (see for example Tang et al.[10]) from the thermodynamic database COST 507 B.[3] The value that can be derived from this database is 21 pct lower at 1873 K than the value given by Yoshikawa and Morita. Elements that are major slag components will also be present at low percentages in silicon after equilibration. The influence of these elements on the activity of boron is discussed for each slag system later in this article.

Teixeira et al.[6] calculated the activity coefficient of boron oxide as a function of slag composition using the Henrian activity coefficient of boron in silicon found by Yoshikawa and Morita.[8] In addition, they used the distribution coefficient of boron that they had determined in their own work. The activity coefficient had a maximum value for intermediate basicities and decreased both for lower and higher basicities. In addition, they combined 11B NMR measurements of the slag with quantum chemical calculations of the chemical shift. From this, they found boron to be tetrahedrally coordinated and charge compensated by Ca2+ at a basicity (CaO/SiO2 mass ratio) of 0.55 and 0.61. They also found boron to be at a Q4 site in the slag.

The Henrian activity coefficient of boron oxide was determined by using the distribution coefficient of boron in this work as well. To keep it simple, this activity coefficient will be denoted as the activity coefficient of boron oxide even if it is in the dilute range and likely to behave as a Henrian solute throughout this article.

Teixeira and Morita[7] defined the borate capacity as a measure of the affinity of a slag for boron. This measure is defined so that it is independent of the partial pressure of oxygen. The definition from their work is given by Eqs. [6] to [8]. The oxidation and ionization reaction is defined as

where

The borate capacity is defined as

where f is the activity coefficient expressed in mass percent. They found the borate capacity to increase with increasing basicity of the investigated slags.

Johnston and Barati[11] normalized the distribution coefficient from a previous study[12] by the oxygen partial pressure:

They did this to investigate the effect of basicity and found that increasing basicity is favorable for removing boron.

The normalization is similar to the borate capacity defined by Morita and Teixeira.[7] Therefore, the equations for \( C_{{{\text{BO}}_{3}^{3 - } }} \) and \( D_{\text{B}} \) only differ by a constant factor at dilute concentrations of boron.

Experimental Determination of the Thermodynamic Properties of Boron Oxide

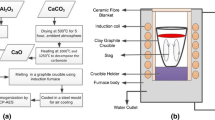

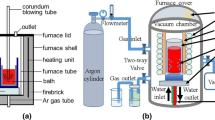

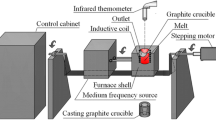

The distribution of boron between silicon and different binary and ternary slags in the CaO-MgO-Al2O3-SiO2 system was determined by the present authors in a previous article.[13] Before the experiments, either slag or silicon was doped with around 100 ppm mass of boron. Slag and silicon were then charged in equal amounts into a graphite crucible and inserted into an enclosed furnace. The material was heated under argon atmosphere to 1873 K (1600 °C) and held at that temperature for 6 to 9 hours to ensure chemical equilibrium between slag and silicon. The temperature at the end of a typical experiment, logged right below the crucible, is shown in Figure 1.

The cooling rate is important, as it is crucial to cool fast enough to avoid re-equilibration at lower temperatures than investigated. Equilibration with respect to boron took several hours; therefore, a cooling rate of about 100 K per minute was considered sufficient. More details about the experimental procedure can be found in Reference 13. Previous experimental works on the distribution coefficient of boron in the CaO-MgO-Al2O3-SiO2 system were also discussed in that article.

The total content of impurities in the slag used in the aforementioned study[13] was measured to be approximately 0.1 pct Fe2O3 and 0.1 pct of other compounds. Most of the iron oxide will be reduced into silicon under the experimental conditions in the present work. The iron content in silicon after the experiments was measured to be up to 500 ppmw, which relates well with the initial iron oxide content in the slags.

The content of impurities in silicon after the experiments was measured and found to be less than 150 ppmw in total, except iron, tungsten, cobalt, and major slag components. Approximately 250 ppmw tungsten and 30 ppmw cobalt were detected, which were likely to have been introduced from the tungsten carbide mill used to make the powdered samples; therefore, they were not considered. Altogether, the total impurity content was considered to be negligible.

The elements constituting the slags will also be present at low concentrations in silicon. The concentration of Mg and Ca in silicon equilibrated with CaO-MgO-SiO2 slags is given in a previous work,[14] and the concentration of Ca and Al in silicon in equilibrium with CaO-Al2O3-SiO2 slags is given in Table I.

The uncertainty of the measured concentrations is expressed as 95 pct confidence intervals based on analyses in three replicate splits. Both in the previous works and in this work, the confidence intervals were calculated using the Student’s t-distribution. For analyses in three replicate splits, this means that the standard deviation of the mean was multiplied by a factor of 4.303.

Discussion

In equilibrium between slag and silicon, we have

We see that the partial pressure of oxygen increases with the increasing activity of silica, where the upper limit is given by unit activty of silica. A lowered activity of silicon (by adding other elements) could also increase the partial pressure of oxygen, but this is not practical considering that the primary goal is to remove boron from relatively pure silicon. The equilibrium given by Eq. [11] can be used together with Eq. [4] to express the distribution coefficient of boron as a function of the partial pressure of oxygen:

where \( K_{3} = K_{1} /K_{2}^{3/4} \). From this expression, we see that a decreased partial pressure of oxygen should reduce the distribution coefficient of boron. All basic oxides reduce the activity of silica when added to a slag, which, in turn, leads to a decreased partial pressure of oxygen according to Eq. [11]. This means that the positive effect of increased basicity on the affinity of the slag for boron, as found by Johnston and Barati[11] and Teixeira and Morita[7] is counteracted by the negative effect of decreased oxygen partial pressure.

In the present work, the defined boron oxide capacity is somewhat different from the borate capacity defined by Teixeira and Morita.[7] The oxidation of boron is given as

From this equation, we can define the boron oxide capacity as

where K′ is the equilibrium constant for Reaction [13] combined with a conversion factor from mole fraction to mass percent. This definition does not assume anything about the local structure of oxidized boron in the slag and is, therefore, a bit simpler in form. It should be noted that the boron oxide capacity is inversely proportional to the activity coefficient of boron oxide.

The Binary CaO-SiO2 System

The distribution of boron between silicon and CaO-SiO2 slags was, as mentioned earlier, determined in a previous study.[13] The concentration of Ca in Si was also experimentally determined, and the activity of silica was estimated from these concentrations in another article.[14] Using these data, the activity coefficient of boron oxide can be determined from Eq. [4]. Gibbs energies of formation of SiO2 (β-cristobalite) from Si (l) and B2O3 (l) from B (l) were taken from the NIST-JANAF tables.[1] The calculated parameters are shown in Table I.

The interaction between boron and calcium may influence the activity of boron in silicon, but limited data for the mixing properties of boron with calcium make it hard to estimate this interaction. Inoue et al.[9] studied the interaction between calcium and boron at 1723 K and found \( \varepsilon_{\text{B}}^{\text{Ca}} \) to be − 3.08. By assuming the same interaction at 1873 K, a calcium content of 1.4 mass pct in silicon will decrease the activity coefficient of boron by about 3 pct relative to pure silicon, which is considered insignificant for the calculations in the present work. The interaction of boron with calcium in silicon, therefore, was neglected when calculating the activity coefficient of boron oxide.

The activity coefficient of boron oxide in the binary CaO-SiO2 system is plotted in Figure 2 as a function of the calcia content. It is seen to decrease with increasing content of calcia, which means that the slag should have a higher affinity for boron at higher calcia contents. This is the same effect of basicity found by Teixeira and Morita[7] and Johnston and Barati.[11]

The activity coefficient of silica is also plotted in Figure 2 and is seen to follow a similar decreasing trend. The partial pressure of the system is controlled by the activity of silica, which means that the partial pressure of oxygen decreases with increasing basicity.

The ratio of the activity coefficients of boron oxide and silica is shown together with the distribution coefficient of boron in Figure 3. The figure shows that the ratio of the activity coefficients does not change much with changing basicity. This means that boron oxide and silica respond in a similar way when the content of the basic oxide calcia increases in the slag.

Figure 4 shows the boron oxide capacity and partial pressure of oxygen plotted as a function of basicity in the binary CaO-SiO2 system. The boron oxide capacity is inversely proportional to the activity coefficient of boron oxide in the slag, as can be seen in Eq. [14]. Therefore, the partial pressure of oxygen and the boron oxide capacity are seen to have opposite trends in Figure 4. This illustrates why the distribution coefficient remains almost unchanged with changing calcia content in the binary CaO-SiO2 system.

From a physical point of view, the network is broken down and the slag becomes less polymerized with increasing calcia content. This reaction stabilizes both silica and dilute boron oxide in the slag phase, since both are network forming oxides that have a strong negative interaction with calcia. Therefore, the activity coefficients of both silica and boron oxide decrease with increasing calcia content in the slag, as can be seen in Figure 2.

Kline et al.[15] investigated the structure of the CaO-SiO2 system with the addition of boron oxide using Raman spectroscopy. They found boron oxide to behave as a network former in a similar way as silica, which is also well documented elsewhere in the literature.

There is a slight decrease in the ratio of the activity coefficients at intermediate basicities, as can be seen in Figure 3. This indicates that boron oxide is slightly more stabilized in the slag than silica.

Hence, intermediate basicities seem to be optimal for stabilizing tetrahedrally coordinated boron oxide relative to silica. Teixeira et al.[6] have, as previously discussed, shown that boron oxide is tetrahedrally coordinated and charge compensated with Ca2+ at Q4 sites. At intermediate basicities, there is a relatively large concentration of Ca2+ for charge compensation and there are many Q4 sites in the structure. At higher basicities, there are less Q4 sites, which causes the activity coefficient of boron oxide to increase relative to the activity coefficient of silica. At lower basicities, there are limited Ca2+ for charge compensation, causing the activity coefficient of boron oxide to increase relative to the activity coefficient of silica.

This effect is masked when observing the distribution coefficient of boron. The masking is caused by the difference in valency between boron and silicon together with the activity coefficient of silica, which decreases with increasing basicity.

From Kline et al.,[15] it can be seen that the Q2 species in the slag are peaking at intermediate basicities in the binary CaO-SiO2 system. Sakamoto et al.[16] also found Q2 species to peak at intermediate basicities in the ternary CaO-SiO2-BO1.5 system using MAS-NMR.

The Ternary CaO-MgO-SiO2 System

The same approach as for the binary CaO-SiO2 system was used to calculate the activity coefficient of boron oxide in the ternary CaO-MgO-SiO2 system, using data from the previous studies.[13,14] The calculated parameters in the ternary CaO-MgO-SiO2 system are shown in Table II.

The interaction between boron and magnesium in silicon was estimated using the FactSage FTlite database. In this database, the binary B-Si, Mg-Si, and B-Mg systems are all assessed, but none of the assessments have been published. The interaction between boron and magnesium in silicon is calculated in Factsage by ternary interpolation of the binary systems. The highest magnesium content was measured at 0.74 mass pct.[14] At this level, the activity of boron was calculated to be 1.6 pct lower than in pure silicon, which was considered insignificant for the calculations in the present work. The calcium content in the ternary CaO-MgO-SiO2 system is lower than in the binary CaO-SiO2 system. Therefore, the influence of calcium on the activity of boron is considered insignificant in the CaO-MgO-SiO2 system as well.

The same trend for the activity coefficients of boron oxide and silica as in the binary CaO-SiO2 system is also seen in the ternary CaO-MgO-SiO2 system. In Figure 5, the ratios between the activity coefficient of boron oxide and silica from both the binary CaO-SiO2 and MgO-SiO2 systems, and the ternary CaO-MgO-SiO2 system, are plotted as a function of basicity. The ratio is not seen to change much. The distribution coefficient of boron is also plotted in Figure 5 and is similarly seen not to change much with changing basicity.

Magnesia is observed to have the same effect on the activity coefficients of silica and boron oxide as calcia had in the binary CaO-SiO2 system. Both calcia and magnesia are basic oxides and have the same effect on the activity coefficient of silica and the activity coefficient of dilute boron oxide. As a result, the distribution coefficient of boron is almost unaffected by changing slag composition in the ternary CaO-MgO-SiO2 system. This also means that the oxygen partial pressure of the system and the boron oxide capacity of the slag balance each other in the same way as in the binary CaO-SiO2 system.

Kline[17] investigated the structure of the CaO-MgO-SiO2 system with addition of boron oxide using Raman spectroscopy. He found the structural changes to be the same as in the CaO-SiO2 system[15] when adding boron oxide. This also is in line with the finding that the distribution coefficient of boron is unaffected when exchanging calcia with magnesia. The second consequence is that the distribution coefficient is almost unaffected by basicity also in the ternary CaO-MgO-SiO2 system.

From Kline,[17] it can be seen that there is a peak of Q2 species at intermediate basicities in the ternary CaO-MgO-SiO2 system in the same way as in the binary CaO-SiO2 system. The trend of the ratio of the activity coefficients of boron oxide and silica is almost identical as in the binary CaO-SiO2 system, as can be seen in Figure 5. This indicates that boron oxide is stabilized relative to silica at intermediate basicities also in the ternary CaO-MgO-SiO2 system. Kline found that there is also a minimum of Q1 species at intermediate basicities in the ternary CaO-MgO-SiO2 system, but this does not seem to have any additional influence on the activity coefficient of boron oxide in the slag. In addition, Kline found the abundance of Q2 species to decrease and Q1 species to increase when replacing calcia with magnesia at constant silica content. These changes do, however, not seem to affect the ratio of the activity coefficients of boron oxide and silica.

The Ternary CaO-Al2O3-SiO2 System

In a previous study,[13] the distribution coefficient of boron was determined for the CaO-Al2O3-SiO2 system. It was found to decrease with increasing alumina content in the slag.

The calcium and aluminum concentration in silicon is relatively high in equilibrium with the slags with the highest alumina content. The measured aluminum and calcium concentrations in silicon in equilibrium with different slags are shown in Table III. These concentrations were measured in parallel with the boron content given in a previous study.[13] Experiments CAS1 and CAS2 were not considered to have been in equilibrium with respect to boron; therefore, these experiments were not used in the evaluation of the results.

The activity of silicon will be affected when the concentration of calcium and aluminum increases. Silicon follows Raoult’s law for low contents of calcium and aluminum. At higher contents of calcium, the activity of silicon will become lower than predicted by Raoult’s law. The activity of silicon will also be lower than predicted by Raoult’s law at higher aluminum contents, but the deviation from Raoult’s law is smaller than for calcium. For experiment CAS6, the activity of silicon was calculated to be 1.5 pct lower than predicted by Raoult’s law using the FactSage FTlite database. This was considered insignificant for the calculations in the present work, and the activity of silicon, therefore, was assumed to follow Raoult’s law.

There is some interaction between boron and aluminum in liquid silicon, but the aluminum content in silicon is too low in the present work to have a noticeable effect on the activity of boron. The activity of boron was calculated to decrease by 0.6 pct at an aluminum content of 2.6 mass pct relative to pure silicon using the FactSage FTlite database. The interaction between aluminum and boron in silicon is calculated in Factsage by ternary interpolation of the binary B-Si, Al-B, and Al-Si systems. The assessments of these binary systems have not been published. The calcium content, on the other hand, is so high that it may have an influence on the activity of boron. The interaction coefficient between boron and calcium from Inoue et al.[9] of − 3.08, therefore, was employed when calculating the activity coefficient of boron oxide.

The activity of silica is needed to calculate the activity coefficient of boron oxide. The activity coefficient of boron oxide was calculated using activities of silica from the FactSage FToxid database. The CaO-Al2O3-SiO2 system was assessed by Pelton et al.,[18] and the parameters from their optimization are used in the FToxid database. The activity coefficients of silica and boron oxide are plotted in Figure 6 as a function of Al2O3/(Al2O3 + SiO2), and both activity coefficients are seen to decrease with an increasing Al2O3/(Al2O3 + SiO2) ratio at constant CaO content. Experiments CS4 and CS7 from the binary CaO-SiO2 system were used in the plot as nonalumina containing slags. The activity coefficients are also seen to become more similar with increasing Al2O3/(Al2O3 + SiO2) ratio. The activity coefficients are listed in Table IV together with the activity of silica and the distribution coefficient of boron determined in a previous study.[13]

The ratio of the activity coefficients of boron oxide and silica is plotted as a function of Al2O3/(Al2O3 + SiO2) in Figure 7, and it is seen to increase with increasing Al2O3/(Al2O3 + SiO2) ratio. Experiments CS4 and CS7 were also included in this plot as nonalumina containing slags. This increase of the activity coefficient of boron oxide relative to the activity coefficient of silica is the reason why the distribution coefficient of boron decreases with increasing alumina content.

The activity coefficients of both boron oxide and silica decrease with increasing Al2O3/(Al2O3 + SiO2) ratio in the slag at constant CaO content. This indicates that both boron oxide and silica have a negative interaction with alumina. However, the interaction between silica and alumina is stronger than the interaction between boron oxide and alumina. This causes the ratio between the activity coefficient of boron oxide and silica to increase with increasing alumina content. The different interactions may be explained by looking at the structure.

The oxygen partial pressure of the system decreases with increasing Al2O3/(Al2O3 + SiO2) ratio in the slag at constant CaO content. At the same time, the boron oxide capacity of the slag increases. Both these effects were also observed in the binary CaO-SiO2 system and the ternary CaO-MgO-SiO2 system. In this system, however, the boron oxide capacity does not fully balance the decreased oxygen partial pressure.

Kline[17] investigated the structure of the ternary CaO-Al2O3-SiO2 system. He found the relative abundance of Q2 species to decrease and the abundance of Q1 species to increase with increasing Al2O3/(Al2O3 + SiO2) ratio. The same trend was observed in the CaO-MgO-SiO2 system when replacing calcia with magnesia at constant silica content. In this case, however, the ratio of the activity coefficients of boron oxide and silica increases with increasing alumina content in the slag. Some other mechanism than Qn speciation, therefore, may also be influencing the activity coefficient of boron oxide.

Merzbacher et al.[19] showed that aluminum is tetrahedrally coordinated and mostly located at Q4 sites in silica-rich CaO-Al2O3-SiO2 slags. Alumina needs to be charge compensated by Ca2+ to be incorporated in the liquid slag with a tetrahedral structure. The charge compensation reaction can be written in two reaction steps. In the first step, alumina bonds with free oxygen and assumes tetrahedral coordination:

The tetrahedrally coordinated aluminum then bonds with Ca2+ to achieve charge neutrality:

Altogether, we have the reaction

Hence, with increasing alumina content, free oxygen anions and Ca2+ in the melt will decrease:

Boron oxide, as discussed previously, has been shown to be tetrahedrally coordinated at low concentrations in calcium-silicate slags.[6] The same reactions as for alumina, therefore, also apply to boron oxide:

The equilibrium constant for the charge-compensation reaction is, hence, given as

The ratio \( a_{{{\text{BCa}}_{0.5} {\text{O}}_{2} }} /a_{{{\text{BO}}_{1.5} }} \) can be expressed as the ratio of tetrahedrally orientated boron ([4]B) to trigonally orientated boron ([3]B):

By rearranging Eq. [20] and differentiating with respect to alumina, we obtain

Since boron is most stable in tetrahedral coordination, the activity of boron oxide should decrease relative to the activity coefficient of silica with increasing \( v_{\text{B}} \):

Hence, we get

In other words, the activity coefficient of boron oxide should increase relative to the activity coefficient of silica with increasing content of alumina, as shown in Figure 7. This means that the expected behavior, from a structural perspective, of boron oxide in the slag fits well with the experimentally measured behavior.

Teixeira et al.[6] determined that boron was located at Q4 sites in CaO-SiO2 slags at dilute concentrations. Merzbacher et al.[19] showed that aluminum is located mostly at Q4 sites in silica-rich CaO-Al2O3-SiO2 slags. This may contribute to an increased activity coefficient of boron oxide relative to the activity coefficient of silica, when the alumina content in the slag increases, since boron and aluminum compete for the same structural sites. However, this effect will be challenging to separate from the simultaneous effect of charge compensation with Ca2+.

Johnston and Barati[12] found increasing alumina content to decrease the distribution coefficient of boron in the quaternary CaO-MgO-Al2O3-SiO2 system. In a previous article,[13] these results were found to fit well with the effect of increasing alumina content in the ternary CaO-Al2O3-SiO2 system. This indicates that alumina may have the same effect on the distribution coefficient of boron when added to the ternary CaO-MgO-SiO2 system as when added to the binary CaO-SiO2 system.

Conclusions

Silica and dilute boron oxide respond in a similar way to changing content of the basic oxides calcia and magnesia in slags. The ratio of the activity coefficients of boron oxide and silica is the parameter that mainly determines how the distribution coefficient of boron changes with slag composition.

Increasing the content of the basic oxides calcia and magnesia decreases the activity of silica, which causes the partial pressure of oxygen in the system to decrease. Increased basicity does, however, also decrease the activity coefficient of boron oxide in the slag by an almost equal magnitude as the activity coefficient of silica.

The slag, therefore, has an increasing boron oxide capacity with increasing basicity, but the reduced partial pressure of the system counteracts this and leads the distribution coefficient of boron to be almost unaffected by slag composition in both the binary CaO-SiO2 and the ternary CaO-MgO-SiO2 system.

It was found that intermediate basicities give the lowest ratio of the activity coefficients of boron oxide and silica in both the binary CaO-SiO2 and the ternary CaO-MgO-SiO2 system. This means that intermediate basicities are optimal for stabilizing boron oxide in the slag relative to silica. Looking at the structure, intermediate basicities are optimal because there is Ca2+ available for charge compensation of boron oxide at the same time as there are Q4 sites available in the slag.

Addition of alumina to the binary CaO-SiO2 system, on the other hand, decreases the activity coefficient of silica more than the activity coefficient of boron oxide. The partial pressure of oxygen, therefore, decreases more relative to the activity coefficient of boron oxide. This leads the distribution coefficient of boron to decrease with increasing alumina content in the slag.

Boron oxide and alumina are tetrahedrally coordinated in the slag and both, therefore, need Ca2+ for charge compensation. An increase of the alumina content in the slag means that there is less Ca2+ available for charge compensation of tetrahedrally coordinated boron oxide. Hence, the activity coefficient of boron oxide is increased relative to the activity coefficient of silica by the presence of alumina in the slag.

Notes

It should be noted that the trend of the activity coefficient of boron oxide is not affected by an adjustment of the value of the Henrian activity coefficient of boron in silicon: only the magnitude will be changed. Therefore, the exact value of the activity coefficient is not critical for the evaluations done in this work.

References

M.W. Chase: NIST-JANAF Thermochemical Tables (J. Phys. Chem. Ref. Data Monograph No. 9), American Institute of Physics, College Park, MD, 1998.

S.A. Decterov, V. Swamy, and I.-H. Jung: Int. J. Mater. Res., 2007, vol. 98, pp. 987–94.

I. Ansara, M.H. Rand, and A.T. Dinsdale: COST 507—Thermochemical Database for Light Metal Alloys, 1998, vol. 2.

R. Noguchi, K. Suzuki, F. Tsukihashi, and N. Sano: Metall. Mater. Trans. B, 1994, vol. 25B, pp. 903–07.

K. Suzuki, T. Sugiyama, K. Takano, and N. Sano: J. Jpn. Inst. Met., 1990, vol. 54, pp. 168–72.

L.A.V. Teixeira, Y. Tokuda, T. Yoko, and K. Morita: ISIJ Int., 2009, vol. 49, pp. 777–82.

L.A.V. Teixeira and K. Morita: ISIJ Int., 2009, vol. 49, pp. 783–87.

T. Yoshikawa and K. Morita: Mater. Trans., 2005, vol. 46, pp. 1335–40.

G. Inoue, T. Yoshikawa, and K. Morita: High Temp. Mater. Processes, 2003, vol. 22, pp. 221–26.

K. Tang, E.J. Øvrelid, G. Tranell, and M. Tangstad: Mater. Trans., 2009, vol. 50, pp. 1978–84.

M.D. Johnston and M. Barati: J. Non-Cryst. Solids, 2011, vol. 357, pp. 970–75.

M.D. Johnston and M. Barati: Solar Energy Materials and Solar Cells, 2010, vol. 94, pp. 2085–90.

L.K. Jakobsson and M. Tangstad: Metall. Mater. Trans. B, 2014, vol. 45B, pp. 1644–55.

L.K. Jakobsson and M. Tangstad: Metall. Mater. Trans. B, 2015, vol. 46B, pp. 595–605.

J. Kline, M. Tangstad, and G. Tranell: Metall. Mater. Trans. B, 2015, vol. 46B, pp. 62–73.

M. Sakamoto, Y. Yanaba, H. Yamamura, and K. Morita: ISIJ Int., 2013, vol. 53, pp. 1143–51.

J. Kline: Structures of CaO-SiO2, CaO-MgO-SiO2 and CaO-Al2O3-SiO2 Slags and with the Addition of B2O3: A Raman Spectroscopic Study, Doctoral Thesis, NTNU, Trondheim, 2013.

A.D. Pelton, S.A. Degterov, G. Eriksson, C. Robelin, and Y. Dessureault: Metall. Mater. Trans. B, 2000, vol. 31B, pp. 651–59.

C.I. Merzbacher, B.L. Sherriff, J.S. Hartman, and W.B. White: J. Non-Cryst. Sol., 1990, vol. 124, pp. 194–206.

Acknowledgments

This work was financially supported by The Research Council of Norway through the BASIC project (191285/V30).

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted June 25, 2017.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Jakobsson, L.K., Tangstad, M. Thermodynamics of Boron Removal from Silicon Using CaO-MgO-Al2O3-SiO2 Slags. Metall Mater Trans B 49, 1699–1708 (2018). https://doi.org/10.1007/s11663-018-1250-7

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-018-1250-7