Abstract

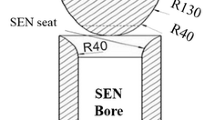

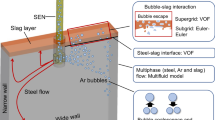

The effects of nozzle design on dispersed, two-phase flows of the steel-argon system in a slab mold are studied using a water-air model with particle image velocimetry and ultrasound probe velocimetry techniques. Three nozzle designs were tested with the same bore size and different port geometries, including square (S), special bottom design with square ports (U), and circular (C). The meniscus velocities of the liquid increase two- or threefold in two-phase flows regarding one-phase flows using low flow rates of the gas phase. This effect is due to the dragging effects on bubbles by the liquid jets forming two-way coupled flows. Liquid velocities (primary phase) along the narrow face of the mold also are higher for two-phase flows. Flows using nozzle U are less dependent on the effects of the secondary phase (air). The smallest bubble sizes are obtained using nozzle U, which confirms that bubble breakup is dependent on the strain rates of the fluid and dissipation of kinetic energy in the nozzle bottom and port edges. Through dimensionless analysis, it was found that the bubble sizes are inversely proportional to the dissipation rate of the turbulent kinetic energy, ε0.4. A simple expression involving ε, surface tension, and density of metal is derived to scale up bubble sizes in water to bubble sizes in steel with different degrees of deoxidation. The validity of water-air models to study steel-argon flows is discussed. Prior works related with experiments to model argon bubbling in steel slab molds under nonwetting conditions are critically reviewed.

Similar content being viewed by others

References

R. Sánchez-Pérez, R.D. Morales, L. García-Demedices, J. Palafox-Ramos, and M. Díaz-Cruz: Metall. Mater. Trans. B, 2004, vol. 35B, pp. 85–99.

J. Knoepke, M. Hubbard, J. Kelly, R. Kittridge, and J. Lucas: Steelmaking Conf. Proc., ISS, Warrendale, PA, 1994, vol. 77, pp. 381–88.

H. Yamamura, Y. Mizukami, and K. Misawa: ISIJ Int., 1996, vol. 36, pp. S223–S226.

H. Esaka, Y. Kuroda, K. Shinozuka, and M. Tamura: ISIJ Int., 2004, vol. 44, pp. 682–90.

Z. Wang, K. Mukai, and I. Jae Lee: ISIJ Int., 1999, vol. 39, pp. 553–62.

G. Kaptay and K.K. Kelemen: ISIJ Int., 2001, vol. 41, pp. 305–07.

J. Sengupta, Brian G. Thomas, Ho-Jung Shin, and Seon-Hyo Kim: AISTech 2006 Proc., vol. 1, pp. 903–14.

W.H. Emling and T.A. Waugaman: Steelmaking Conf. Proc., ISS, Warrendale, PA, 1994, vol. 77, pp. 371–79.

Y. Mizuno and M. Iguchi: ISIJ Int., 2001, vol. 41 (Suppl.), pp. S56–S60.

T. Szirtes: Applied Dimensional Analysis and Modeling, McGraw-Hill Book Company, New York, NY, 1997, pp. 1–787.

M. Iguchi, H. Ueda, and T. Uemura: Int. J. Multiphase Flows, 1995, vol. 21, pp. 861–73.

H. Bai and Brian G. Thomas: Metall. Mater. Trans. B, 2001, vol. 32B, pp. 253–67.

H. Bai and Brian G. Thomas: Metall. Mater. Trans. B, 2001, vol. 32B, pp. 269–84.

Z. Liu, B. Li, and M. Jiang: Metall. Mater. Trans. B, 2014, vol. 45B, pp. 675–97.

Y. Miki and S. Takeuchi: ISIJ Int., 2003, vol. 43, pp. 1548–55.

E. Torres-Alonso, R.D. Morales, S. Garcia-Hernández, and J. Palafox-Ramos: Metall. Mater. Trans. B, 2010, vol. 41B, pp. 598–97.

E. Torres-Alonso, R.D. Morales, and S. Garcia-Hernández: Metall. Mater. Trans. B, 2010, vol. 41B, pp. 675–90.

Z. Liu, L. Li, F. Qi, B. Li, M. Jiang, and F. Tsukihashi: Metall. Mater. Trans. B, 2015, vol. 46B, pp. 406–20.

I. Calderón-Ramos and R.D. Morales: Metall. Mater. Trans. B, 2015, vol. 46B, pp. 1314–25.

I. Calderón-Ramos, R.D. Morales, and María Salazar-Campoy: Steel Res. Int., 2016, vol. 87, pp. 1154–67.

José DeJBarreto, R.D. Morales, S. García‐Hernández, A. Nájera‐Bastida, and I. Calderón‐Ramos: Steel Res. Int., 2015, vol. 86, pp. 517–27

S. García-Hernández, J. de J. Barreto, R.D. Morales, and H. Arcos-Gutiérrez: ISIJ Int., 2013, vol. 53, pp. 809–17.

R. Sánchez-Pérez, R.D. Morales, M. Díaz-Cruz, O. Olivares-Xometl, and J. Palafox-Ramos: ISIJ Int., 2003, vol. 43, pp. 637–46.

M. Iguchi and O.J. Ilegbusi: Modeling Multiphase Materials Processes, 1st ed., Springer Science+Business Media, LLC, New York, NY, 2011, pp. 95–174.

J.C. Delgado-Pureco: Arcelor Mittal Steel, Lázaro Cárdenas, Michoacán.

ImageJ-1.49 (Image Processing and Analysis in Java): http://imagej.nih.gov/ij/index.html. Accessed 10 Dec 2015.

C. Crowe, M. Sommerfeld, and Y. Tsuji: Multiphase Flows with Droplets and Particles, 1st ed., CRC Press LLC, New York, NY, 1998, pp. 40–44.

M. Iguchi and N. Kasai: Metall. Mater. Trans. B, 2000, vol. 31B, pp. 453–60.

D.C. Wilcox: Turbulence Models for CFD, La Cañada Flintridge, CA, 2000, pp. 10–13.

C. Martinez-Bazán: Ph.D. Thesis, University of California at San Diego, San Diego, 1998.

G.M. Evans, G.D. Rigby, T.A. Honeyands, and Q.L. He: Chem. Eng. Sci., 1999, vol. 54, pp. 4861–67.

F. Oeters: Metallurgy of Steelmaking, Stahl und Eisen, Berlin, 1989, pp. 167–80.

E.T. Turkdogan: Fundamentals of Steelmaking, The Institute of Materials, London, 1996, pp. 125–36.

A. Ghosh: Secondary Steelmaking, CRC Press, London, 2001, pp. 225–52.

R. Clift, J.R. Grace, and M.E. Weber: Bubbles, Drops and Particles, Academic Press, New York, NY, 1978, pp. 26–29 and 172.

Z. Wang, K. Mukai, Z. Ma, M. Nishi, H. Tsukamoto, and Feng Shi: ISIJ Int., 1999, vol. 39, pp. 795–803.

E. Sven, K. Timmel, N. Shevchenko, M. Röder, M. Anderhuber, and P. Gardin: Experimental Investigation of Liquid Metal Two-Phase Flows in a Continuous Casting Model, 8th ECCC, 2015.

K. Timmel, N. Shevchenko, M. Röder, M. Anderhuber, P. Gardin, S. Eckert, and G. Gerbeth: Metall. Mater. Trans. B, 2015, vol. 36B, pp. 700–10

R. Chaudhary, C. Ji, and B.G. Thomas: CCC Report No. 201013, Aug. 12, 2010.

S. Uno and R.C. Kitner: AIChE J., 1956, pp. 420–25.

Acknowledgments

The authors thank the National Council of Science and Technology and the program IPN-PIFI for grant scholarships to MMSC. RDM thanks IPN and SNI for their support of his research group.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted January 27, 2016.

Appendix A

Appendix A

Equation [1A] in text is rewritten here:

As an example, the square, 3 × 3 matrix A is located in the right corner of the subsequent general matrix. The 3 × 1 matrix in the left corner is B. The C matrix is built by 1 × 3 elements and is located just below matrix A. Finally, the D matrix with 1 × 1 elements (called the identity matrix) is that located just below matrix B. Matrices A and B constitute the complete dimensional matrix, whereas matrixes C and D constitute the matrix of dimensionless numbers, as shown in Figure A1.

The variables used to build the dimensional matrix were the following: Db is the bubble diameter (m), σm-s is the surface tension metal (kg/s2), ρm is the metal density (kg/m3), ε is the dissipation of kinetic energy (m2/s3), \( \pi_{1} \) is a constant number equal to 1.26.[26]

Rights and permissions

About this article

Cite this article

Salazar-Campoy, M.M., Morales, R.D., Nájera-Bastida, A. et al. A Physical Model to Study the Effects of Nozzle Design on Dispersed Two-Phase Flows in a Slab Mold Casting Ultra-Low-Carbon Steels. Metall Mater Trans B 49, 812–830 (2018). https://doi.org/10.1007/s11663-018-1181-3

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-018-1181-3