Abstract

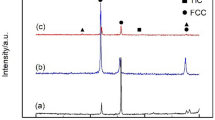

A Fe3Al-Fe3AlC x composite was prepared using reactive liquid processing (RLP) through controlled mixture of carbon steel and aluminum in the liquid state. The microstructure and phases of the composite were assessed using X-ray diffraction, scanning electron microscopy, energy-dispersive X-ray spectroscopy, optical microscopy, and differential scanning calorimetry. In addition, the density, hardness, microhardness, and elastic modulus were evaluated. The Fe3Al-Fe3AlC x composite consisted of 65 vol pct Fe3Al and 35 vol pct Fe3AlC x (κ). The κ phase contained 10.62 at. pct C, resulting in the stoichiometry Fe3AlC0.475. The elastic modulus of the Fe3Al-Fe3AlC0.475 composite followed the rule of mixtures. The RLP technique was shown to be capable of producing Fe3Al-Fe3AlC0.475 with a microstructure and properties similar to those achieved using other processing techniques reported in the literature.

Similar content being viewed by others

References

C. G. McKamey, C.T. Liu, J. V. Cathart, S. A. David, E. H. Lee: Technical Report, ORNL:TM-10125, Oak Ridge National Lab, Oak Ridge, 1986.

C.G. McKamey, J.H. DeVan, P.F. Tortorelli, V.K. Sikka: J. Mater. Res., (1991), vol. 6, pp. 1779-1805.

P.F. Tortorelli, K. Natesan: Mater. Sci. Eng. A, (1998), vol. 258, pp. 115–125.

N.S. Stoloff: Mater. Sci. Eng. A, (1998), vol. 258, pp. 1–14.

S.C. Deevi, V.K. Sikka: Intermetallics. (1996), vol. 4, pp. 357–375.

N.S. Stoloff, C.T. Liu, S.C. Deevi: Intermetallics. (2000), vol. 8, pp. 1313–1320.

J.H. Devan, P.F. Tortorelli: Corros. Sci.,(1993), vol. 35, 1065–1071.

P.F. Tortorelli, J.H. DeVan: Mater. Sci. Eng. A, (1992), vol. 153, pp. 573–577.

S. Banovic, J. DuPont, A. Marder: Scr. Mater., (1998), vol. 38, pp. 1763–1767.

H. Halfa: J. Miner. Mater. Charact. Eng., (2010), vol. 9, pp. 775–786.

N. Cinca, C.R.C. Lima, J.M. Guilemany: J. Mater. Res. Technol., (2013), vol. 2, pp. 75–86.

C.T.T. Liu, J. Stringer, J.N.N. Mundy, L.L.L. Horton, P. Angelini: Intermetallics. (1997), vol. 5, pp. 579–596.

N.S. Stoloff, C.T. Liub: Intermetallics. (1994), vol. 2, pp. 75–87.

W.C. Luu, J.K. Wu: Mater. Chem. Phys., (2001), vol.70, pp. 236–241.

R.G. Baligidad, U. Prakash, A. Radhakrishna, V.R. Rao, P.K. Rao, and N.B. Ballal: Scr. Mater., 1997, vol. 36, pp. 105–09.

R.G. Baligidad and A. Radhakrishna: Mater. Sci. Eng. A, 2000, vol. 287, pp. 17–24.

R.G. Baligidad, A. Radhakrishna, V.R. Rao, P.K. Rao, N.B. Ballal: Scr. Mater. (1997), vol. 36, pp. 667–671.

S.M. Zhu, X.S. Guan, K. Shibata, K. Iwasaki: Metall. Mater. Trans. A, (2002), vol. 33, pp. 1292–1295.

J. Yang, P. La, W. Liu, J. Ma, Q. Xue: Intermetallics. (2005), vol. 13, pp. 1184–1189.

T. Itoi, S. Mineta, H. Kimura, K. Yoshimi, M. Hirohashi: Intermetallics. (2010), vol. 18, pp. 2169–2177.

A. Radhakrishna, R.G. Baligidad, D.S. Sarma: Scr. Mater. (2001), vol. 45, pp. 1077–1082.

R.G. Baligidad, U. Prakash, A.R. Krishna: Malerials Sci. Eng. A, (1997), vol. 230, pp. 188–193.

V.A. Andryushchenko, V.G. Gavrilyuk, V.M. Nadutov: Ph. MET. Metallography, (1985), vol. 60, pp. 50-55.

D. Connétable, P. Maugis: Intermetallics. (2008), vol. 16, pp. 345–352.

D. Feijó, L. Borges, D. Crocce, R. Espinosa, C. Geraldo: J. Mater. Res. Technol., (2014), vol. 3, pp. 101–106.

R.G. Baligidad, U. Prakash, and A. Radhakrishna: Intermetallics., 1998, vol. 6, pp. 765–769.

A. Schneider, L. Falat, G. Sauthoff, G. Frommeyer: Intermetallics. (2005), vol. 13, pp. 1322–1331.

R.G. Baligidad, U. Prakash, A. Radhakrishna: Materials Sci. Eng. A, (1997), vol. 231, pp. 206–210.

R.G. Baligidad, A. Radhakrishna, U. Prakash: Materials Sci. Eng. A, (1998), vol. 257, pp. 235–239.

V.S. Rao, R.G. Baligidad, V.S. Raja: Corros. Sci., (2002), vol. 44, pp. 521–533.

U. Prakash, G. Sauthoff: Scr. Mater., (2001), vol. 44, pp. 73–78.

J. Yang, P. La, W. Liu, Y. Hao: Mater. Sci. Eng. A, (2004), vol. 382, pp. 8–14.

M.S. Archana, R.C. Gundakaram, Y.S. Rao, V.V.S.S. Srikanth, S.V. Joshi, J. Joardar: Mater. Sci. Eng. A, (2014), vol. 611, pp. 298–305.

K. Isonishi: Mater. Sci. Forum, (2007), vol. 534–536, pp. 189–192.

C. Shen, Z. Pan, Y. Ma, D. Cuiuri, H. Li: Addit. Manuf., (2015), vol. 7, pp. 20–26.

S. Deevi, V. Sikka, C. Liu: Prog. Mater. Sci., (1997), vol. 42, pp. 177–192.

V.K. Sikka, D. Wilkening, J. Liebetrau, B. Mackey: Mater. Sci. Eng. A, (1998), vol. 258, pp. 229–235.

U. Prakash: Trans. Indian Inst. Met., (2008), vol. 61, pp. 193–199.

G. Giunchi, G. Ripamonti, T. Cavallin, E. Bassani: Cryogenics, (2006), vol. 46, pp. 237–242.

Odegard, A. Bronson: JOM, (1997), vol. 49, pp. 52–54.

D. Zhu, M. Gao, H. Pan, Y. Liu, X. Wang, Y. Pan, F.J. Oliveira, J.M. Vieira: Ceram. Int., (2013), vol. 39, pp. 3831–3842.

A. Il’inskii, S. Slyusarenko, O. Slukhovskii, I. Kaban, and W. Hoyer: Mater. Sci. Eng. A, 2002, vol. 325, pp. 98–102.

V.S. Rao: J. Mater. Sci., (2004), vol. 39, pp. 4193–4198.

PDF 00-050-0955 (ICDD, 2015).

J. Kopecek, P. Kratochvíl, D. Rafaja, D. Plischke: Intermetallics, (1999), vol. 7, pp. 1367–1372.

PDF 00-029-0044 (ICDD, 2015).

J. A. Jiménez, G. Frommeyer: J. Alloys Compd., (2011), vol. 509, pp. 2729–2733.

ASTM International, ASTM E1876-09, Standard Test Method for Dynamic Young’s Modulus, Shear Modulus, and Poisson’s Ratio by Impulse Excitation of Vibration, West Conshohocken, PA, 2009.

R. Besson, A. Legris: Phys. Rev. B, (2008), vol. 78, pp. 1–11.

Legarra, E. Apiñaniz, F. Plazaola: Intermetallics, (2010), vol. 18, pp. 1288–1292.

M. Palm, G. Inden: Intermetallics, (1995), vol. 3, pp. 443–454.

V.I. Moravetski, V.A. Andryushchenko, L.M. Sheludchenko: J. Phys. Chem. Solids, (1994), vol. 55, pp. 195–200.

R.S. Sundar, R.G. Baligidad, Y.V.R.K. Prasad, D.H. Sastry: Mater. Sci. Eng. A, (1998), vol. 258, pp. 219–228.

A.T. Phan, M.-K.Paek, Y.-B. Kang: Acta Mater., (2014), vol. 79, pp. 1–15.

V. Raghavan: J. Phase Equilibria, (1993), vol. 14, pp. 615–617.

H. Ohtani, M. Yamano, M. Hasebe: ISIJ Int., (2004), vol. 44, pp. 1738–1747.

K. Yoshimp: Mater. Sci. Eng. A, (1995), vol. 194, pp. 53–61.

H. Mehrer, M. Eggersmann, A. Gude, M. Salamon, B. Sepiol: Mater. Sci. Eng. A, (1997), vol. 240, pp. 889–898.

F. Stein, A. Schneider, G. Frommeyer: Intermetallics, (2003), vol. 11, pp. 71–82.

I. Ohnuma, C.G. Schon, R. Kainuma, G. Inden, K. Ishida: Acta Mater., (1998), vol. 46, pp. 2083–2094.

R.T. Fortnum, D.E. Mikkola: Mater. Sci. Eng., (1987), vol. 91, pp. 223–231.

L. Anthony, B. Fultz: Acta Metall. Mater., (1995), vol. 43, pp. 3885–3891.

U. R Kattner, B. P. Burton, In: Okamoto H, editor. Binary Alloy Phase diagrams. Materials Park, OH: ASM International; 1993. pp. 2-44.

K.C.H. Kumar, V. Raghavan: J. Phase Equilibria, (1991), vol. 12, pp. 275–286.

M. Palm: Intermetallics, (2005), vol. 13, pp. 1286–1295.

R. Kant, U.P. Vijaya, A.V. V Satya Prasad: Trans. Indian Inst. Met., (2016). vol. 69, pp. 845–850.

C. T. Liu, K. S. Kumar: JOM, (1993), vol. 45, pp. 38-44.

E. Frutos, D.G. Morris: Intermetallics, (2013), vol. 38, pp. 1–3.

M. Friák, J. Deges, R. Krein, G. Frommeyer, J. Neugebauer: Intermetallics, (2010), vol. 18, pp. 1310–1315.

W. Sanders, G. Sauthoff: Intermetallics, (1997), vol. 5, pp. 377–385.

W.D. Callister Jr. and D.G. Rethwisch: Materials Science and Engineering: An Introduction, 8th ed. Wiley, 2009, pp. 630.

Acknowledgments

This research was supported by the Department of Mechanical Engineering of UTFPR and UFPR, which provided testing facilities, and the Fersul Cast Iron Foundry, which provided the experimental setup. We thank Tiffany Jain, M.S., from Edanz Group (www.edanzediting.com/ac) for editing a draft of this manuscript.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted March 9, 2017.

Rights and permissions

About this article

Cite this article

Verona, M.N., Setti, D. & Paredes, R.S.C. Microstructure and Properties of Fe3Al-Fe3AlC x Composite Prepared by Reactive Liquid Processing. Metall Mater Trans B 49, 529–536 (2018). https://doi.org/10.1007/s11663-017-1161-z

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-017-1161-z