Abstract

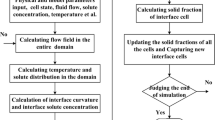

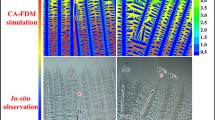

A cellular automaton (CA)–finite difference model is developed to simulate dendrite growth and solute diffusion during solidification process in the molten pool of Al-Cu alloy. In order to explain the interaction between the dendritic growth and solute distribution, a series of CA simulations with different solute diffusion velocity coefficients are carried out. It is concluded that the solute concentration increases with dendrite growing and solute accumulation in the dendrite tip. Converged value of the dendrite tip growth velocity is about 480 μm/s if the mesh size is refined to 2 μm or less. Growth of the primary dendrite and the secondary dendrite is mainly influenced by solute diffusion at the dendrite tips. And growth of secondary and tertiary dendrites is mainly influenced by solute diffusion at interdendrite.

Similar content being viewed by others

References

S.G.R. Brown and N.B. Bruce: Scripta Metall. Mater., 1995, vol. 32, pp. 241–6.

S.A. David, S.S. Babu, and J.M. Vitek: Trans. JWRI, 1996, vol. 25, pp. 127–43.

M.A. Martorano, C. Beckermann, and C.A. Gandin: Metall. Mater. Trans. A, 2003, vol. 34, pp. 1657–74.

C.A. Gandin and M. Rappaz: Acta Mater., 1997, vol. 45, pp. 2187–95.

T.M. Wang, S.W. Cai, J. Li, J.J. Xu, Z.N. Chen, J. Zhu, Z.Q. Cao, and T.J. Li: China Foundry, 2010, vol. 7, pp. 61–7.

M. Bedel, G. Reinhart, A.A. Bogno, C.A. Gandin, S. Jacomet, E. Boller, H. Nguyen-Thi, and H. Henein: Acta Mater., 2015, vol. 89, pp. 234–46.

S. Karagadde, L. Yuan, N. Shevchenko, S. Eckert, and P.D. Lee: Acta Mater., 2014, vol. 79, pp. 168–80.

K.P. Young and D.H. Kerkwood: Metall. Trans. A, 1975, vol. 6, pp. 197–205.

Y. Miyata, T. Suzuki, and J.I. Uno: Metall. Trans. A, 1985, vol. 16, pp. 1799–1805.

A. Farzadi, M. Doquang, S. Serajzadeh, A.H. Kokabi, G. Amberg: Model. Simul. Mater. Sci. Eng., 2008, vol. 16, pp. 1932–6.

Y. Lu, C. Beckermann, and J.C. Ramirez: J. Cryst. Growth, 2005, vol. 280, pp. 320–34.

W.J. Zheng, Z.B. Dong, Y.H. Wei, K.J. Song, J.L. Guo, and Y. Wang: Comput. Mater. Sci., 2013, vol. 82, pp. 525–30.

A. Choudhury, K. Reuther, E. Wesner, A. August, B. Nestler, and M. Rettenmayr: Comput. Mater. Sci., 2012, vol. 55, pp. 263–8.

V. Fallah, M. Amoorezaei, N. Provatas, S.F. Corbin, and A. Khajepour: Acta Mater., 2012, vol. 60, pp. 1633–46.

K.J. Song, Y.H. Wei, Z.B. Dong, X.H. Zhan, W.J. Zheng, and K. Fang: Model. Simul. Mater. Sci. Eng., 2014, vol. 22, pp. 15006–23.

Y. Chen, X.B. Qi, D.Z. Li, X.H. Kang, and N.M. Xiao: Comput. Mater. Sci., 2015, vol. 104, pp. 155–61.

K. Reuther and M. Rettenmayr: J. Comput. Phys., 2014, vol. 279, pp. 63–6.

Y. Yang, J.W. Garvin, and H.S. Udaykumar: Int. J. Heat Mass Transf., 2005, vol. 48, pp. 5270–83.

L. Tan and N. Zabaras: J. Comput. Phys., 2007, vol. 226, pp. 131–55.

X.H. Zhan, Z.B. Dong, Y.H. Wei, and R. Ma: J. Cryst. Growth, 2009, vol. 311, pp. 4778–83.

X.H. Zhan, Y.H. Wei, and Z.B. Dong: J. Mater. Process. Technol., 2008, vol. 208, pp. 1–8.

Y.H. Wei, X.H. Zhan, Z.B. Dong, and L. Yu: Sci. Technol. Weld. Join., 2013, vol. 12, pp. 138–46.

A.B. Dong, S.J. Wang, R. Ma, Y.H. Wei, K.J. Song, and G.F. Zhai: J. Mater. Sci. Technol. (Shenyang, China), 2011, vol. 27, pp. 183–8.

L. Beltran-Sanchez and D.M. Stefanescu: Metall. Mater. Trans. A, 2003, vol. 34, pp. 367–82.

M.B. Cortie: Metall. Trans. B, 1993, vol. 24, pp. 1045–53.

C.A. Gandin, J.L. Desbiolles, M. Rappaz, and P. Thevoz: Metall. Mater. Trans. A, 1999, vol. 30, pp. 3153–65.

L. Beltran-Sanchez and D.M. Stefanescu: Int. J. Cast Met. Res., 2002, vol. 15, pp. 251–6.

M.A. Zaeem and S.D. Felicelli: J. Mater. Sci. Technol., 2012, vol. 28, pp. 137–46.

M.A. Zaeem, H. Yin, and S.D. Felicelli: Appl. Math. Model., 2013, vol. 37, pp. 3495–503.

L. Wei, X. Lin, M. Wang, and W. Huang: Comput. Mater. Sci., 2012, vol. 54, pp. 66–74.

M. Zhu, D. Sun, S. Pan, Q. Zhang, and D. Raabe: Model. Simul. Mater. Sci. Eng., 2014, vol. 22, pp. 384–7.

W. Tan and Y.C. Shin: Comput. Mater. Sci., 2015, vol. 98, pp. 446–58.

X.F. Zhang and J.Z. Zhao: J. Cryst. Growth, 2014, vol. 391, pp. 52–8.

R. Chen, Q. Xu, and B. Liu: Comput. Mater. Sci., 2015, vol. 105, pp. 90–100.

H. Yin and S.D. Felicelli: Acta Mater., 2010, vol. 58, pp. 1455–65.

H. Yin, S.D. Felicelli, and L. Wang: Acta Mater., 2011, vol. 59, pp. 3124–36.

S.C. Michelic, J.M. Thuswaldner, and C. Bernhard: Acta Mater., 2010, vol. 58, pp. 2738–51.

B. Jelinek, M. Eshraghi, S. Felicelli, J.F. Peters: Comput. Phys. Commun., 2014, vol. 185, pp. 939–47.

M. Eshraghi, S.D. Felicelli, and B. Jelinek: J. Cryst. Growth, 2012, vol. 354, pp. 129–34.

L. Nastac: Acta Mater., 1999, vol. 47, pp. 4253–62.

C. Moore: Physica D (Amst., Neth.), 1998, vol. 111, pp. 27–41.

C. Moore and J. Machta: J. Stat. Phys., 2000, vol. 99, pp. 661–90.

H.B. Dong and P.D. Lee: Solid State Phenom., 2005, vol. 53, pp. 659–68.

L. Beltran-Sanchez and D.M. Stefanescu: Metall. Mater. Trans. A, 2004, vol. 35A, pp. 2471–85.

S. Luo and M.Y. Zhu: Comput. Mater. Sci., 2013, vol. 71, pp. 10–8.

Acknowledgments

This work was supported by National Natural Science Foundation of China (Grant No. U1637103).

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted January 10, 2017.

Rights and permissions

About this article

Cite this article

Zhan, X., Gu, C., Liu, Y. et al. Effect of Solute Diffusion on Dendrite Growth in the Molten Pool of Al-Cu Alloy. Metall Mater Trans B 48, 2685–2694 (2017). https://doi.org/10.1007/s11663-017-1056-z

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-017-1056-z