Abstract

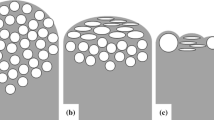

Closed-cell foams were produced from re-melted aluminum alloy scrap that contained 0.13 wt pct Mg magnesium in the as-received state and higher levels after adding 1, 2, or 5 wt pct Mg. The excess Mg gave rise to the fragmentation of long oxide filaments present in the scrap alloy into smaller filaments and improved its distribution and wetting by the Al matrix. Foaming the re-melted scrap alloy containing 1, 2, and 5 wt pct Mg excess showed stability and good expansion in comparison to the scrap alloy containing 0.13 wt pct Mg only, but the cells became non-equiaxed when the Mg concentration was high (≥2 wt pct excess) due to cell wall rupture during solidification. Compressibility and energy absorption behavior were studied for scrap alloy foams containing 1 wt pct Mg excess, which is the optimum level to obtain good expansion, stability, and uniform cell size. Foams with densities in the range of 0.2 to 0.4 g cm−1 produced by holding at the foaming temperature for different times were used for the investigation. A uniform cell structure led to flatter stress plateaus, higher energy absorption efficiencies, and reduced “knockdown” in strength compared with commercial foams made by gas bubbling. The mechanical performance found is comparable to that of commercial foams made by a similar method but the expected costs are lower.

Similar content being viewed by others

References

J. Banhart, Prog. Mater. Sci., 2001. vol. 46, pp. 559-632.

L. Drenchev, J. Sobczak, S. Malinov, W. Sha, Mater.Sci. Technol., 2006, vol. 22, pp. 1135-47.

S. W. Ip, S.Y.Wang, J. M. Toguri, Can. Metall. Q, 1999, vol. 38, pp. 81-92.

J. Banhart: JOM, J. Miner. Metals Mater. Soc., 2000, vol. 52, pp. 22–27.

N. Babcsán, D. Leitlmeier, H.P. Degischer, Materialwiss.Werkstofftech., 2003, vol.34, pp. 22-29.

N. Babcsán, F.Garcia-Moreno, J. Banhart, Colloids Surf., A, 2007,vol.309, pp. 254-63.

G. S. Vinod Kumar, M. Chakraborty, F. Garcia-Moreno, J. Banhart, Metall. Mater. Trans. A, 2011, vol.42, pp. 2898-908.

J. Banhart, Adv. Eng. Mater., 2006,vol.8, pp.781-94.

W. Ha, S. K. Kim, H.H Jo, Y.J Kim, Mater.Sci.Technol., 2005, vol.21, pp. 495-99.

M. Haesche, D. Lehmhus, J. Weise, M. Wichmann, I. C. M.Mocellin, J. Mater.Sci. Technol.,2010, vol.26, pp. 845-50.

G. S. Vinod Kumar, K. Heim, F. Garcia-Moreno, J. Banhart, A. R. Kennedy, Adv. Eng. Mater., 2013, vol.15, pp.129-33.

G. S. Vinod Kumar, K. Heim, F. Garcia-Moreno, J. Banhart, A. R. Kennedy,.Int. J. Mater. Res., 2015, vol.106, pp. 978-87.

M. Mukherjee, U. Ramamurty, F. Garcia-Moreno, J. Banhart, Acta Mater., 2010, vol.58, pp. 5031-42.

E. Andrews, W. Sanders, L.J. Gibson, Mater. Sci. Eng. A, 1999, vol.270, pp. 113-24.

V. Gergely and B. Clyne, Adv. Eng. Mater., 2000, vol.2, pp.175-78.

O.Olurin, N. Fleck, M. Ashby, Mater. Sci. Eng. A, 2000, vol.291, pp.136-46.

A. E. Simoneand L.J. Gibson, Acta Mater., 1998. vol.46, pp.3109-23.

T. Miyoshi, M. Itoh, S. Akiyama, A. Kitahara, Adv. Eng. Mater., 2000, vol.2, pp. 179-83.

U. Ramamurty, A. Paul, Acta Mater., 2004, vol.52, pp.869-76.

B.C. Pai, G. Ramani, R. M. Pillai, K. G. Satyanarayana, J.Mater.Sci., 1995, vol.30, pp. 1903-11.

S.Y. Kim, Y.S. Um, B.Y. Hur,Mater. Sci. Forum, 2006, vol. 510-511, pp. 902-5, 2006

M. Mukherjee,F.Garcia-Moreno, J. Banhart, Scripta Mater., 2010, vol.63, pp. 235-38.

Acknowledgments

The corresponding author thanks German DFG, Grants GA 1304/2-1 and BA 1170/17-1 and Indian Naval Research Board, Grants NRB-317/MAT/13-14 for the support provided to this study.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted February 21, 2017.

Rights and permissions

About this article

Cite this article

Vinod-Kumar, G.S., Heim, K., Jerry, J. et al. Effect of Magnesium Addition on the Cell Structure of Foams Produced From Re-melted Aluminum Alloy Scrap. Metall Mater Trans B 48, 2551–2563 (2017). https://doi.org/10.1007/s11663-017-1043-4

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-017-1043-4