Abstract

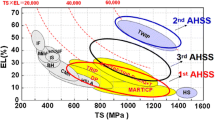

The characteristics of inclusions in Fe-16Mn-xAl-0.6C (x = 0.002, 0.033, 0.54, 2.10 mass pct) steels have been investigated and their effects on hot ductility of the high manganese TWIP steels have been discussed. Ductility is very poor in the steel containing 0.54 mass pct aluminum, which is lower than 20 pct in the temperature range of 873 K to 1473 K (600 °C to 1200 °C). For the steels containing 0.002 and 2.10 mass pct aluminum, ductility is higher than 40 pct in the same temperature range. The hot ductility of steel containing 0.033 mass pct aluminum is higher than 30 pct throughout the temperature range under examination. With increasing aluminum content, the main inclusions in the steels change along the route of MnO/(MnO + MnS) → MnS/(Al2O3 + MnS) → AlN/(Al2O3 + MnS)/(MgAl2O4 + MnS) → AlN. The thermodynamic results of inclusion types calculated with FactSage software are in agreement with the experimental observation results. The inclusions in the steels containing 0.002 mass pct aluminum do not deteriorate the hot ductility. MnS inclusions whose average size, number density, and volume ratio are 1.12 μm, 15.62 mm−2, and 2.51 × 10−6 in the steel containing 0.033 mass pct aluminum reduce the ductility. In the steel containing 0.54 mass pct aluminum, AlN inclusions whose average size, number density, and volume ratio are 0.878 μm, 16.28 mm−2 and 2.82 × 10−6 can precipitate at the austenite grain boundaries, prevent dynamic recrystallization and deteriorate the hot ductility. On the contrary, in the steel containing 2.10 mass pct aluminum, the average size, number density and volume ratio of AlN inclusions change to 2.418 μm, 35.95 mm−2, and 2.55 × 10−5. They precipitate in the matrix, which do not inhibit dynamic recrystallization and thereby do not lead to poor hot ductility.

Similar content being viewed by others

References

G. Frommeyer, U. Brüx and P. Neumann: ISIJ Int., 43 (2003), 438.

A. S. Hamada and L. P. Karjalainen: Mater. Sci. Eng. A, 528 (2011), 1819.

O. Grässel, L. Krüger, G. Frommeyer and L. W. Meyer: Int. J. Plast., 16 (2000), 1391.

S. Allain, J. P. Chateau and O. Bouaziz: Mater. Sci. Eng. A, 387–389 (2004), 143.

L. Chen, H. S. Kim, S. K. Kim and B. C. De Cooman: ISIJ Int., 47 (2007), 1804.

W. T. Nachtrab and Y. T. Chou: Metall. Trans. A, 19 (1988), 1305.

S. Harada, S. Tanaka, H. Misumi, S. Mizoguchi and H. Horiguch: ISIJ Int., 30 (1990), 310.

B. Mintz, R. Abushosha and M. Shaker: Mater. Sci. Technol., 9 (1993), 907.

B. Mintz: ISIJ Int., 39 (1999), 833.

J. Calvo, J. M. Cabrera, A. Rezaeian and S. Yue: ISIJ Int., 47 (2007), 1518.

L. H. Chowna and L. A. Cornish: Mater. Sci. Eng. A, 494 (2008), 263.

K. R. Carpenter, R. Dippenaar and C. R. Killmore: Mater. Metall. Trans. A, 40 (2009), 573.

X. M. Chen, S. H. Song, Z. C. Sun, S. J. Liu, L. Q. Weng and Z. X. Yuan: Mater. Sci. Eng. A, 527 (2010), 2725.

J. I. Kömi and L. P. Karjalainen: Effect of restoration kinetics on hot ductility of a ferritic-austenitic and super austenitic stainless steels, in: Proceedings of International Conference on Stainless Steels, Dusseldorf, Germany, 1996, p. 301.

J. Liu, G. W. Fan, P. De Han, J. S. Liu, J. Q. Gao and J. F. Yang: Mater. Sci. Forum, 620-622 (2009), 161.

F. Shi, L. J. Wang, W. F. Cui, Z. B. Li, M. Z. Xu and C. M. Liu: Mater. Sci. Forum, 575-578 (2008), 1056.

S. W. Hwang, J. H. Ji and K. T. Park: Mater. Sci. Eng. A, 528 (2011), 7267.

S. E. Kang, J. R. Banerjee, E. M. Maina and B. Mintz: Mater. Sci. Technol., 29 (2013), 1225.

S. E. Kang, J. R. Banerjee, A. S. Tuling and B. Mintz: Mater. Sci. Technol., 30 (2014), 486.

S. E. Kang, J. R. Banerjee, A. Tuling and B. Mintz: Mater. Sci. Technol., 30 (2014), 1328.

I. Mejía, A. E. Salas-Reyes, A. Bedolla-Jacuinde, J. Calvo and J. M. Cabrera: Mater. Sci. Eng. A, 616 (2014), 229.

A. E. Salas-Reyes, I. Mejía, A. Bedolla-Jacuinde, A. Boulaajaj, J. Calvo and J. M. Cabrera: Mater. Sci. Eng. A, 611 (2014), 77.

A. Dumay, J. P. Chateau, S. Allain, S. Miget and O. Bouaziz: Mater. Sci. Eng. A, 483-484 (2008), 184.

K. T. Park, K. G. Jin, S. H. Han, S. W. Hwang, K. Choi and C. S. Lee: Mater. Sci. Eng. A, 527 (2010), 3651.

A. S. Hamada, L. P. Karjalainen and M. C. Somani: Mater. Sci. Eng. A, 467 (2007), 114.

M. Koyama, T. Sawaguchi, K. Ogawa, T. Kikuchi and M. Murakami: Mater. Sci. Eng. A, 497 (2008), 353.

Y. Kim, N. Kim, Y. Park, I. Choi, G. Kim, S. Kim and K. Cho: J. Kor. Inst. Metall. Mater., 46 (2008), 780.

J. M. Jang, S. J. Kim, N. H. Kang, K. M. Cho and D. W. Suh: Metall. Mater. Int., 15 (2009), 909.

K. Ahn, D. Yoo, M. H. Seo, S. H. Park and K. Chung: Metall. Mater. Int., 15 (2009), 637.

K. G. Jin, C. Y. Kang, S. Y. Shin, S. Hong, S. Lee, H. S. Kim, K. H. Kim and N. J. Kim: Mater. Sci. Eng. A, 528 (2011), 2922.

J. Kim, S. J. Lee and B. C. De Cooman: Scripta Mater., 65 (2011), 363.

B. Mintz, S. Yue and J. J. Jonas: Int. Mater. Rev., 36 (1991), 187.

H. Su, W. D. Gunawadarna, A. Tuling and B. Mintz: Mater. Sci. Technol., 23 (2007), 1357.

B. Mintz, A. Tuling and A. Delgado: Mater. Sci. Technol., 19 (2003), 1721.

S. E. Kang, A. Tuling, J. R. Banerjee, W. D. Gunawardana and B. Mintz: Mater. Sci. Technol., 27 (2011), 95.

S. E. Kang, J. R. Banerjee and B. Mintz: Mater. Sci. Technol., 28 (2012), 589.

B. Mintz and D. N. Crowther: Int. Mater. Rev., 55 (2010), 168.

C. W. Bale, P. Chartrand, S. A. Degterov, G. Eriksson, K. Hack, R. Ben Mahfoud, J. Melancon, A. D. Pelton and S. Peterson: Calphad, 26 (2002), 189.

C. W. Bale, E. Belisle, P. Chartrand, S. A. Decterov, G. Eriksson, K. Hack, I.-H. Jung, Y.-B. Kang, J. Melancon, A. D. Pelton, C. Robelin and S. Peterson: Calphad, 33 (2009), 295.

R. T. DeHoff and F. N. Rhines: Quantitative Microscopy, McGraw-Hill, New York, (1968), 158.

R. Abushosha, R. Vipond and B. Mintz: Mater. Sci. Technol., 7 (1991), 1101.

B. Mintz and R. Abushosha: Mater. Sci. Technol., 8 (1992), 171.

N. Hansen and B. Bay: Acta Metall., 29 (1981), 65.

R. D. Doherty and J. W. Martin: Trans. Am. Soc. Met., 57 (1964), 874.

G. A. Osinkolu, M. Tacikowski and A. Kobylanski: Mater. Sci. Technol., 1 (1985), 520.

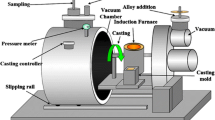

J. Yang, Y. N. Wang, X. M. Ruan, R. Z. Wang, K. Zhu, Z. J. Fan, Y. C. Wang, C. B. Li and X. F. Jiang: Mater. Metall. Trans. B, 46 (2015), 1365.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted September 22, 2015.

Rights and permissions

About this article

Cite this article

Wang, YN., Yang, J., Wang, RZ. et al. Effects of Non-metallic Inclusions on Hot Ductility of High Manganese TWIP Steels Containing Different Aluminum Contents. Metall Mater Trans B 47, 1697–1712 (2016). https://doi.org/10.1007/s11663-016-0626-9

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-016-0626-9