Abstract

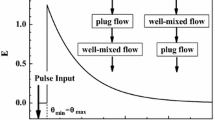

“Combined Model” is often applied to characterize the fluid flow in tundishes. There are different ways to manage the calculation of this model, while the most recently used is introduced by SAHAI and EMI. But this approach may lead to incorrect results in some special cases. In this paper, a new method based on the F-Curve is proposed to analyze the fluid flow in tundishes, and the relationship between E-Curve and F-Curve is concerned. In the end, their application to tundish fluid flow has been outlined. The dead volume calculated by the new method is much close to the results of dye experiment and the numerical simulation.

Similar content being viewed by others

Abbreviations

- E :

-

Dimensionless concentration obtained by pulse input

- F :

-

Dimensionless concentration obtained by step input

- θ :

-

Dimensionless time scale

- \( \bar{t} \) :

-

Mean residence time (=V/Q)

- \( \bar{t}_{\text{c}} \) :

-

Measured mean residence time up to two times the \( \bar{t} \)

- \( V_{\text{a}} \) :

-

Volume of active region in a tundish

- \( Q_{\text{a}} \) :

-

Volumetric flow rate through the active region of a tundish

- V :

-

Volume of liquid in a tundish

- Q :

-

Total volumetric flow rate through a tundish

- \( \frac{{V_{\text{d}} }}{V} \) :

-

Fraction of dead volume in a tundish

- \( \frac{{V_{\text{a}} }}{V} \) :

-

Fraction of active volume in a tundish

- \( \frac{{V_{\text{m}} }}{V} \) :

-

Fraction of well-mixed volume in a tundish

- \( \frac{{V_{\text{p}} }}{V} \) :

-

Fraction of the plug volume in a tundish

- V 2 :

-

Volume of the flow fluid which stays in the vessel for a period longer than two times the mean residence time

References

IISI Committee on Technology: IISI study on clean steel: State of the Art and Process Technology in Clean Steelmaking, International Iron and Steel Institute, Brussels, 2004, pp. 276-79.

O. Levenspiel: Chemical Reaction Engineering, 3rd ed., John Wiley & Sons, New York, 2001, p.261-65.

Y. Sahai and T. Emi: ISIJ Int., 1996, vol. 36, pp. 667-72.

S. P. Ferro, R. J. Principe and M. B. Goldschmit: Metall. Mater. Trans. B, 2001, vol. 32, pp. 1185-93.

5.S. Lopez-Ramirez, J. De, J. Barreto, J. Palafox-Ramos, RD Morales, D. Zacharias: Metall Mater Trans B, 2001, vol. 32, pp. 615-27.

G. Solorio-Díaz and R. D. Morales, A. Ramos-Banderas: Int. J. Heat Mass Transfer, 2005, vol. 48, pp. 3574-90.

G. H. Wen, Y. F. Huang, P. Tang, and M. M. Zhu: Int. J. Miner. Metall. Mater., 2012, vol. 19, pp. 15-20.

S. N. Lekakh and D. G. C. Robertson: ISIJ Int., 2013, vol. 53, pp. 622-28.

K. Takahashi, M. Ando and T. Ishii: ISIJ Int., 2014, vol. 54, pp. 304-10.

Y. Sahai and Emi T: Tundish Technology for Clean Steel Production, World Scientific Publishing Co. Pte. Ltd., Singapore, 2008, pp. 105-07.

R. Pardeshi, S. Basak, A. K. Singh, B. Basu, V. Mahashabde, S. K. Roy and S. Kumar: ISIJ Int., 2004, vol. 44, pp. 1534-40.

X. W. Zhang, X. L. Jin, Y. Wang, K. Deng and Z. M. Ren: ISIJ Int., 2001, vol. 51, pp. 581-87.

R. Chaudhary, C. Ji, B. G. Thomas and S. P. Vanka: Metall. Mater. Trans. B, 2011, vol. 42, pp. 987-1001.

A. Braun, M. Warzecha and H. Pfeifer: Metall. Mater. Trans. B, 2010, vol. 41, pp. 549-59.

Acknowledgments

The authors would like to thank Beijing Higher Education Young Elite Teacher Project (No. YETP0411) for the financial support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted August 3, 2014.

Rights and permissions

About this article

Cite this article

Li, D., Cui, H., Liu, Y. et al. A New Method Based on the F-Curve for Characterizing Fluid Flow in Continuous Casting Tundishes. Metall Mater Trans B 47, 1237–1242 (2016). https://doi.org/10.1007/s11663-015-0571-z

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-015-0571-z