Abstract

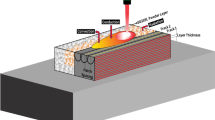

Argon gas commonly is injected into the liquid metal stream through the porous refractory walls in many metallurgical processes. In this work, a new model has been developed to investigate gas diffusion through heated porous refractory, including the effects of refractory geometry, the thermal expansion of the gas, temperature-dependent gas viscosity, and possible leakage into unsealed joints. A novel one-way-flow pressure boundary condition has been formulated and implemented to prevent unrealistic flow into the refractory. The complete model is validated with both analytical solutions of 1D test problems and observations of a water bubbling experiment. Then, to demonstrate practical application of this general model, argon gas flow is simulated through a double-slitted upper tundish nozzle during continuous steel casting with a slide-gate system. Realistic liquid steel pressure distributions with the bubbling threshold condition are applied on the inner surface. Parametric studies are conducted to investigate the effects of joint gas leakage, refractory conductivity, permeability, and injection pressure on the resulting gas distributions, gas mass flow rates, and leakage fraction. This new model of porous flow can serve as the first step of a comprehensive multiphase model system.

Similar content being viewed by others

References

B.G. Thomas: Making, Shaping and Treating of Steel, A. Cramb, ed., 11th edition, vol. 5, Casting Volume, The AISE Steel Foundation, Pittsburgh, PA, 2003, pp. 1–24.

D. Hershey, B.G. Thomas and F.M. Najjar: “Turbulent Flow through Bifurcated Nozzles”, International Journal for Numerical Methods in Fluids, 1993, vol. 17 (1), pp. 23-47.

Y. Xie, S. Orsten and F. Oeters: “Behavior of Bubbles at Gas Blowing into Liquid Wood’s Metal”, ISIJ International, 1992, vol. 32(1), pp. 66-75.

S.T. Johansen, F. Boysan and W.H. Ayers: “Mathematical modelling of bubble driven flows in metallurgical processes”, Applied Scientific Research, 1987, vol. 44, pp. 197-207.

D. Mazumdar and R.I.L. Guthrie: “The Physical and Mathematical Modelling of Gas Stirred Ladle System”, ISIJ International, 1995, vol. 35(1), pp. 1-20.

B. Li, H. Yin, C.Q. Zhou and F. Tsukihashi: “Modeling of three-phase flows and behavior of slag/steel interface in an argon gas stirred ladle”, ISIJ International, 2008, vol. 48(12), pp. 1704-1711.

L. Wang, H. Lee and P. Hayes: “A new approach to molten steel refining using fine gas bubbles”, ISIJ International, 1996, vol. 36(1), pp. 17-24.

A. Vargas-Zamora, R.D. Morales, M. Diaz-Cruz, J. Palafox-Ramos, and J.DE J. Barreto-Sandoval: Metall. Mater. Trans. B., 2004, vol. 35B, pp. 247–57.

H. Bai and B.G. Thomas: Metall. Mater. Trans. B., 2001, vol. 32B, pp. 253–67.

X. Huang and B.G. Thomas: “Modeling of Transient Flow Phenomena in Continuous Casting of Steel”, Canadian Metallurgical Quarterly, 1998, vol. 37(304), pp. 197-212.

T. Shi and B.G. Thomas: Continuous Casting Consortium at University of Illinois at Urbana-Champaign, Report, 2001.

H. Yu and M. Zhu: “Numerical Simulation of the Effects of Electromagnetic Brake and Argon Gas Injection on the Three-dimensional Multiphase Flow and Heat Transfer in Slab Continuous Casting Mold”, ISIJ International, 2008, vol. 48(5), pp. 584–591.

V. Singh, S.K. Dash, J.S. Sunitha: “Experimental Simulation and Mathematical Modeling of Air Bubble Movement in Slab Caster Mold”, 2006, ISIJ International, vol. 46(2), pp. 210-218.

B.G. Thomas, X. Huang, and R.C. Sussman: “Simulation of Argon Gas Flow Effects in a Continuous Slab Caster”, Metallurgical and Materials Trans. B, 1994, vol. 25B, pp. 527-547.

R. Gass: Personal Communication, Inland Steel, 1998.

M. Iguchi, Y. Demoto, N. Sugawara and Z. Morita: “Bubble Behavior in Hg-Air Vertical Bubbling Jets in a Cylindrical Vessel”, ISIJ International, 1992, vol. 32(9), pp. 998-1005.

M. Iguchi, H. Kawabata, K. Nakajima and Z. Morita: “Measurements of bubble characteristics in a molten iron bath at 1600 °C using an electroresistivity probe”, Metallurgical and Materials Trans. B., 1995, vol. 26B, pp. 67-74.

H. Bai and B.G. Thomas: “Bubble Formation during Horizontal Gas Injection into Downward Flowing Liquid”, Metallurgical and Materials Trans. B, 2001, vol. 32B, pp. 1143-1159.

S. Ghaemi, P. Rahimi, and D. Nobes: Physics of Fluids, 2010, vol. 22, pp. 043305 1-15.

N.A. Kazakis, A.A. Mouza and S.V. Paras: “Initial bubble size through a sparger Experimental study of bubble formation at metal porous spargers: Effect of liquid properties and sparger characteristics on the initial bubble size distribution”, Chemical Engineering Journal, 2008, vol. 137, pp. 265-281.

G. Houghton, A.M. McLean, and P.D. Ritchie: “Mechanism of formation of gas bubble-beds”, Chemical Engineering Science, 1957, vol. 7 (1–2), pp. 40–50.

B. Bowonder and R. Kumar: “Studies in bubble formation – IV: bubble formation at porous discs”, Chemical Engineering Science, 1970, vol. 25, pp. 25-32.

G. Lee, B.G. Thomas and S. Kim: “Effect of Refractory Properties on Initial Bubble Formation in Continuous-casting Nozzles”, Metal and Materials International, 2010, vol. 16(3), pp. 501-506.

FLUENT ANSYS Inc. 2007 FLUENT 6.3-Manual (Lebanon, NH).

S. Whitaker: “The Forchheimer equation: a theoretical development”, Transport in Porous Media, 1996, vol. 25, pp. 27-61.

S. Ergun: “Fluid flow through packed columns”, Chemical Engineering Process, 1952, vol. 48(2), pp. 89-94.

Y. Lee: ArcelorMittal Inc. Global R&D, Personal Communication, 2011.

G.M. DÄRR, U. Ludwig: “Determination of permeable porosity”, MATÉRIAUX ET CONSTRUCTIONS, 1973, vol. 6(33), pp. 185-190.

R.E. Collins: in Flow of Fluids Through Porous Materials, C.R. Wilke, ed., Reinhold, Chapman & Hall, London, 1961.

G.H. Fancheark and J.A. Lewis: “Flow of simple fluids through porous refractory”, Industrial and Engineering Chemistry, 1933, vol. 25(10), pp. 1139-1147.

C.A. Sleicher and M.W. Rouse: “A Convenient Correlation for Heat Transfer to Constant and Variable Property Fluids in Turbulent Pipe Flow”, International Journal of Heat and Mass Transfer, 1975, vol.18, pp. 677-683.

P. Wesseling: Principles of Computational Fluid Dynamics, Springer, Berlin, 2001. ISBN 7-03-016677-9, pp. 62.

T. Young: “An essay on the cohesion of fluids”, Philosophical Transactions of the Royal Society of London, 1805, vol.95, pp.65-87.

G. Kaptay, T. Matrushita, K. Mukai and T. Ohuchi: “On different modifications of the capillary model of penetration of inert liquid metals into porous refractories and their connection to the pore size distribution of the refractories”, Metallurgical and Materials Transaction B., 2004, vol. 35B, pp. 471-486.

L. Jimbo, A. Sharan, and A.W. Cramb: 76th Steelmak. Conf. Prof., Dallas, TX, 1993, pp. 485–94.

R. Dawe and E. Smith: “Viscosity of Argon at High Temperatures”, Science, 1969, vol. 163, pp. 675-676.

R. Nunnington: LWB Refractories, Personal Communication, November 6, 2006.

B. van Leer: “Towards the Ultimate Conservative Difference Scheme, V. A Second Order Sequel to Godunov’s Method”, J. Com. Phys., 1997, vol. 135(2), pp. 229–248.

S.V. Patankar: “Numerical Heat Transfer and Fluid Flow”, Hemisphere Publishing Corporation, Washington D.C., 1980.

S.R. Mathur and J.Y. Murthy: “A Pressure-based Method for Unstructured Meshes”, Numerical Heat Transfer, Part B: Fundamentals, 1997, vol. 31(2), pp.195-215.

S. Achaya, B.R. Baliga, K. Karki, J.Y. Murthy, C. Prakash, and S.P. Vanka: “Pressure-based Finite-Volume Methods in Computational Fluid Dynamics”, Journal of Heat Transfer, 1996, vol. 129(7), pp. 407-424.

R. Liu and B.G. Thomas: Proc. AISTech 2012 Steelmak. Conf., Atlanta, GA, 2012, pp. 2235–46.

M. Burty, M. Larrecq, C. Pusse, and Y. Zbaczyniak: “Experimental and Theoretical Analysis of Gas and Metal Flows in Submerged Entry Nozzles in Continuous Casting”, Revue de Metallurgie. Cahiers D’Informations Techniques, 1996, vol. 93(10), pp. 287-292.

J. Sengupta and S.D. Chung: Proc. AISTech 2014 Steelmak. Conf., Indianapolis, IN, 2014, pp. 1857–64.

Acknowledgments

This work was supported by the Continuous Casting Consortium at the University of Illinois. The authors would like to thank Dr. J. Sengupta at ArcelorMittal Dofasco, Dr. H. Yin, and B. Forman at ArcelorMittal Global R&D in East Chicago for their help with the static water bubbling test. The authors also express gratitude to R. Nunnington at Magnesita Refractories for providing data for the parametric studies, and for helpful discussions. Most of all, we thank former graduate student, Zaher Hashisho, now at the University of Alberta, Canada, for initial work on this project.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted February 11, 2014.

Appendix A. Analytical Solution for 1D Test Problem

Appendix A. Analytical Solution for 1D Test Problem

The one-way coupled heat conduction and pressure-source Eqs. [2] and [9] simplify into two ODEs, expressed in cylindrical coordinates as Eqs. [A1] and [A4]. The heat conduction equation,

has the general solution,

The two integration constants, C 1 and C 2, are determined from the fixed temperature boundary conditions at the inner (T 1) and outer radius (T 2):

The 1D gas pressure equation can be expressed as:

Equation [A4] was discretized using a central finite-difference scheme and solved with a tri-diagonal matrix algorithm (TDMA), on a 200-node mesh.[42] Equation [A4] can be solved analytically for two special cases: (1) with gas thermal expansion but constant gas viscosity; and (2) without any thermal effects.

With Thermal Expansion and Constant Gas Viscosity

With constant gas viscosity, the Equation [A4] simplifies to:

which has the following positive general solution:

Applying Eq. [8] gives the corresponding gas velocity:

where integration constants C 1 and C 2 are given in Eq. [A3]. Inserting the fixed pressure boundary conditions, at the inner (P 1) and outer radius (P 2) gives:

No Thermal Effects

The simplest scenario ignores both temperature-dependent gas viscosity and gas expansion. Assuming constant viscosity and temperature simplifies Eq. [A4] into:

which has the pressure solution:

where,

The corresponding gas velocity distribution is: \( V_{\text{r}} = - K_{\text{D}} \frac{{C_{3} }}{r} \).

Rights and permissions

About this article

Cite this article

Liu, R., Thomas, B.G. Model of Gas Flow Through Porous Refractory Applied to an Upper Tundish Nozzle. Metall Mater Trans B 46, 388–405 (2015). https://doi.org/10.1007/s11663-014-0198-5

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-014-0198-5