Abstract

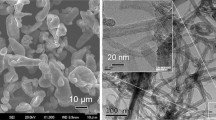

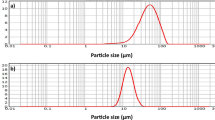

In the present work, a novel technique is introduced called continual annealing and press bonding (CAPB) for the manufacturing of a bulk aluminum matrix composite dispersed with 10 vol pct tungsten carbide particles (Al/WCp composite). The microstructural evolution and mechanical properties of the Al/WCp composite during various CAPB cycles were examined by scanning electron microscopy (SEM), wavelength dispersive X-ray spectroscopy (WDX), and tensile testing. The microstructure of the fabricated composite after fourteen cycles of CAPB showed homogenous distribution of the WC particles in the aluminum matrix and strong bonding between the various layers. According to WDX analysis, the manufactured Al/WCp composite did not evidence the presence of additional elements. The results indicated that the tensile strength of the composites increased with the number of CAPB cycles, and reached a maximum value of 140 MPa at the end of the fourteenth cycle, which was 1.6 times higher than the obtained value for annealed aluminum (raw material, 88 MPa). Even though the elongation of the Al/WCp composite was reduced during the initial cycles of CAPB process, it increased significantly during the final cycles. SEM observation of fracture surfaces showed that the rupture mode in the CAPB-processed Al/WCp composite was of the shear ductile rupture type.

Similar content being viewed by others

References

S. Amirkhanlou and B. Niroumand: T. Nonferr. Met. Soc., 2010, vol. 20, Supplement 3, pp. s788-s793.

M. Zhao, A. Liu, M. Guo, D. Liu, Z. Wang, and C. Wang: Surf. Coat. Technol., 2006, vol. 201, pp. 1655-1659.

R. Jendrzejewski, K. Van Acker, D. Vanhoyweghen, and G. Śliwiński: Appl. Surf. Sci., 2009, vol. 255, pp. 5584-5587.

Y. Saito, N. Tsuji, H. Utsunomiya, T. Sakai, and R. G. Hong: Scripta Mater., 1998, vol. 39, pp. 1221-1227.

Y. Saito, H. Utsunomiya, N. Tsuji, and T. Sakai: Acta Materialia, 1999, vol. 47, pp. 579-583.

E. S. K. Kitazono, K. Kuribayashi: Scripta Mater., 2004, vol. 50, pp. 495–98.

R. Jamaati and M. R. Toroghinejad: Mater. Des., 2010, vol. 31, pp. 4816-22.

R. Jamaati and M. R. Toroghinejad: Mater. Sci. Eng. A, 2010, vol. 527, pp. 7430-35.

R. Jamaati and M. R. Toroghinejad: Mater. Sci. Eng. A, 2010, vol. 527, pp. 4146-51.

R. Jamaati and M. R. Toroghinejad: Mater. Sci. Eng. A, 2010, vol. 527, pp. 4858-63.

R. Jamaati, M. R. Toroghinejad, and A. Najafizadeh: Mater. Sci. Eng. A, 2010, vol. 527, pp. 3857-3863.

R. Jamaati, M. R. Toroghinejad, and A. Najafizadeh: Mater. Sci. Eng. A, 2010, vol. 527, pp. 2720-2724.

R. Jamaati, M. R. Toroghinejad, M. Hoseini, and J. A. Szpunar: Mater. Sci. Eng. A, 2011, vol. 528, pp. 3573-3580.

M. Hashemi, R. Jamaati, and M. R. Toroghinejad: Mater. Sci. Eng. A, 2012, vol. 532, pp. 275-281.

R. Jamaati, M. R. Toroghinejad, J. Dutkiewicz, and J. A. Szpunar: Mater. Des., 2012, vol. 35, pp. 37-42.

M. A. Soltani, R. Jamaati, and M. R. Toroghinejad: Mater. Sci. Eng. A, 2012, vol. 550, pp. 367-374.

S. Amirkhanlou, M. Ketabchi, N. Parvin, S. Khorsand, and R. Bahrami: Materials & Design, 2013, vol. 51, pp. 367-374.

S. Amirkhanlou, R. Jamaati, B. Niroumand, and M. R. Toroghinejad: Mater. Manuf. Processes, 2011, vol. 26, pp. 902-907.

S. Amirkhanlou, M. R. Rezaei, B. Niroumand, and M. R. Toroghinejad: Mater. Des., 2011, vol. 32, pp. 2085-2090.

S. Amirkhanlou, M. R. Rezaei, B. Niroumand, and M. R. Toroghinejad: Mater. Sci. Eng. A, 2011, vol. 528, pp. 2548-2553.

R. Jamaati, S. Amirkhanlou, M. R. Toroghinejad, and B. Niroumand: Mater. Charact., 2011, vol. 62, pp. 1228-1234.

R. Jamaati, S. Amirkhanlou, M. R. Toroghinejad, and B. Niroumand: Mater. Sci. Eng. A, 2011, vol. 528, pp. 2143-2148.

R. Jamaati, S. Amirkhanlou, M. R. Toroghinejad, and B. Niroumand: J. Mater. Eng. Perform., 2011, vol. 21, pp. 1249-1253.

A. Roshanghias, A. H. Kokabi, Y. Miyashita, Y. Mutoh, M. Rezayat, and H. R. Madaah-Hosseini: J. Mater. Sci.-Mater. El., 2012, vol. 23, pp. 1698-1704.

M. Rezayat, A. Akbarzadeh, and A. Owhadi: Metall. Mater. Trans. A, 2012, vol. 43A, pp. 2085-2093.

M. Rezayat, A. Akbarzadeh, and A. Owhadi: Compos. Part A-Appl. S., 2012, vol. 43, pp. 261-267.

M. Rezayat and A. Akbarzadeh: Mater. Des., 2012, vol. 36, pp. 874-879.

C. Y. Liu, R. Jing, Q. Wang, B. Zhang, Y. Z. Jia, M. Z. Ma, and R. P. Liu: Mater. Sci. Eng., A, 2012, vol. 558, pp. 510-516.

C. Y. Liu, Q. Wang, Y. Z. Jia, B. Zhang, R. Jing, M. Z. Ma, Q. Jing, and R. P. Liu: Mater. Sci. Eng., A, 2012, vol. 547, pp. 120-124.

C. Y. Liu, B. Zhang, P. F. Yu, R. Jing, M. Z. Ma, and R. P. Liu: Mater. Sci. Eng. A, 2013, vol. 580, pp. 36-40.

C.W. Schmidt, C. Knieke, V. Maier, H.W. Höppel, W. Peukert, and M. Göken: Scripta Mater., 2011, vol. 64, pp. 245–48.

A. Yazdani and E. Salahinejad: Mater. Des., 2011, vol. 32, pp. 3137-3142.

S. Salimi, H. Izadi, and A. P. Gerlich: J Mater Sci 2011, vol. 46, pp. 409–415.

M. Alizadeh and M. Talebian: Mater. Sci. Eng., A, 2012, vol. 558, pp. 331-337.

S. Amirkhanlou and B. Niroumand: J. Mater. Eng. Perform., 2012, vol. 22, pp. 85-93.

S. Amirkhanlou and B. Niroumand: J. Mater. Process. Technol., 2012, vol. 212, pp. 841-847.

S. Amirkhanlou and B. Niroumand: Mater. Des., 2011, vol. 32, pp. 1895-1902.

A. Ahmadi, M. R. Toroghinejad, and A. Najafizadeh: Mater. Des., 2014, vol. 53, pp. 13-19.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted February 17, 2014.

Rights and permissions

About this article

Cite this article

Amirkhanlou, S., Ketabchi, M., Parvin, N. et al. Structural Evaluation and Mechanical Properties of Aluminum/Tungsten Carbide Composites Fabricated by Continual Annealing and Press Bonding (CAPB) Process. Metall Mater Trans B 45, 1992–1999 (2014). https://doi.org/10.1007/s11663-014-0129-5

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-014-0129-5