Abstract

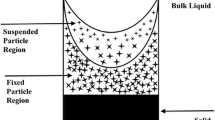

A mathematical model for simulating the electromagnetic field and the evolution of the temperature and velocity fields during solidification of a molten metal subjected to a time-varying magnetic field is described. The model is based on the dual suspended particle and fixed particle region representation of the mushy zone. The key feature of the model is that it accounts for turbulent interactions with the solidified crystallites in the suspended particle region. An expression is presented for describing the turbulent damping force in terms of the turbulent kinetic energy, solid fraction, and final grain size. Calculations were performed for solidification of an electromagnetically stirred melt in a bottom chill mold. It was found that the damping force plays an important role in attenuating the intensity of both the flow and turbulent fields at the beginning of solidification, and strongly depends on the final grain size. It was also found that turbulence drops significantly near the solidification front, and the flow becomes laminarized for solid fraction around 0.3.

Similar content being viewed by others

References

A.A. Tzavaras and H.D. Brody: J. Met., 1984, vol. 36, no. 3, pp. 31-37.

C. Vives: in Magnetohydrodynamics in Process Metallurgy, J. Szekely, J.W. Evans, K. Blazek, and N. El-Kaddah, eds., TMS, Warrendale, PA, 1991, pp. 169–74.

Y.A. Kompan, I. Protokovilov, Y. Fautrelle, Y.U. Gelfgat, and A. Bojarevics: in Modelling for Materials Processing, pp. 85-90, University of Latvia Press, Riga, 2010.

C. Vives and C. Perry: Int. J. Heat Mass Transfer, 1986, vol. 29, pp. 21-33.

Q. Zhao, X. Zhang, C. Feng, N. Zhang, Y. Han, J. Guo, and X. Hou: Adv. Mater. Res., 2012, vols. 482-484, pp. 1447-1452.

K.A. Jackson, J.D. Hunt, and D.R. Uhlmann: Trans TMS-AIME, 1966, vol. 236, pp. 149-158.

B. Willers, S. Eckert, U. Michel, I. Haase, G. Zouhar: Mater. Sci. Eng. A, 2005, vol. 402, pp. 55-65.

J.A. Dantzig and M. Rappaz: Solidification, EPFL Press, Lausanne, 2009, pp. 464-466.

B. Wang, Y. Yang, and W. Tang: Trans. Nonferrous Met. Soc. China, 2008, vol. 18, pp. 536-540.

B. Chalmers: J. Aust. Inst. Met., 1963, vol. 8, pp. 255-263.

R. Mehrabian, M. Keane, and M.C. Flemings: Metall. Trans., 1970, vol. 1, pp. 455-464.

C.M. Oldenburg and F.J. Spera: Numer. Heat Transfer, Part B, 1992, vol. 21, pp. 217-229.

C.J. Parides, R.N. Smith, and M.E. Glicksman: Metall. Mater. Trans. A, 1997, vol. 28, pp. 875-883.

T. Campanella, C. Charbon, and M. Rappaz: Scr. Mater., 2003, vol. 49, pp. 1029-1034.

P.J. Prescott and F.P. Incropera: J. Heat Transf., 1995, vol. 117, pp. 716-724.

P.J. Prescott and F.P. Incropera: J. Heat Transf., 1993, vol. 115, 302–10.

W. Shyy, Y. Pang, G. Hunter, D.Y. Wei, and M.H. Chen: Intl. J. Heat Mass Transf., 1992, vol. 35, 1229–45.

W. Shyy, Y. Pang, G. Hunter, D.Y. Wei, and M.H. Chen: ASME J. Eng. Mater. Technol., 1993, vol. 115, 8-16.

R. Lantzsch, V Galindo, I. Grants, C. Zhang, O. Paetzold, G. Gerbeth, and M. Stelter: J. Crystal Growth, 2007, vol. 305, 249–56.

R. Pardeshi, A.K. Singh, and P. Dutta: Numer. Heat Transfer, Part A, 2008, vol. 55, pp. 42-57.

O. Budenkova, F. Baltaretu, J. Kovács, A. Roósz, A. Rónaföldi, A.M. Bianchi, and Y. Fautrelle: IOP Conf. Ser.: Mater. Sci. Eng., 2012, vol. 33, 012046.

Y. Yamagishi, H. Takeuchi, A.T. Pyatenko, and N. Kayukawa: AIChE J., 1999, vol. 45, pp. 696-707.

J.L. Alvarado, C. Marsh, C. Sohn, G. Phetteplace, and T. Newell: Int. J. Heat Mass Transfer, 2007, vol. 50, pp. 1938-1952.

S. Wenji, X. Rui, H. Chong, H. Shihui, D. Kaijun, and F. Ziping: Int. J. Refrig., 2009, vol. 32, pp. 1801-1807.

E. Kolbe and W. Reiss: Wiss. Z. der TH Ilmenau, 1963, vol. 9, 311–17.

R.F. Dudley and P.E. Burke: IEEE Trans. Indu. Appl., 1972, vol. 8, 565-571.

N. El-Kaddah and J. Szekely: J. Fluid Mech., 1983, vol. 133, 37-46.

J.L. Meyer, N. El-Kaddah, J. Szekely, C. Vives, and R. Ricou: Metall. Trans. B, 1987, vol. 18, 529–38.

H. Tennekes and J.L. Lumley: A First Course in Turbulence, pp. 19-20, MIT Press, Cambridge, 1972.

W. P. Jones and B.E. Launder: Int. J. Heat Mass Transfer, 1972, vol. 15, pp. 301-314.

D.G. Thomas: J. Colloid Sci., 1965, vol. 20, pp. 267-277.

P. Bradshaw, D.H. Ferriss, and N.P. Atwell: J. Fluid Mech., 1967, vol. 28, pp. 593-616.

B.E. Launder and D.B. Spalding: Mathematical Models of Turbulence, p. 78, Academic Press, London, 1972.

W.M. Pun and D.B. Spalding: Report HTS/76/2, Imperial College of Science and Technology, London, August 1977.

S.V. Patankar: Numerical Heat Transfer and Fluid Flow, Hemisphere Publishing, New York, NY, 1980.

G. Poole, N. Rimkus, A. Murphy, P. Boehmcke, and N. El-Kaddah: in Magnesium Technology, S.N. Mathaudhu, W.H. Sillekens, N.R. Neelmeggham, and N. Hort, eds., Wiley, New York, NY, 2012, pp. 161–64.

L. Nastac and N. El-Kaddah: IOP Conf. Ser.: Mater. Sci. Eng., 2012, vol. 33, 012084.

Acknowledgment

The authors graciously thank the National Science Foundation for their funding of this project under Grant CMMI-0856320.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted May 24, 2013.

Appendix A. The Damping Force in the Suspended Particle Region

Appendix A. The Damping Force in the Suspended Particle Region

In the suspended particle region, the fluctuating velocity of the solid particles is zero, and the instantaneous velocity of the two-phase mixture is

The instantaneous Navier–Stokes equation in this region can then be written as

Taking the time average of [A2] yields

where τ t is the Reynolds stress tensor. From Eqs. [11] and [A3], the damping force is given by

Rights and permissions

About this article

Cite this article

Poole, G.M., El-Kaddah, N. An Improved Model for the Flow in an Electromagnetically Stirred Melt during Solidification. Metall Mater Trans B 44, 1531–1540 (2013). https://doi.org/10.1007/s11663-013-9944-3

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-013-9944-3