Abstract

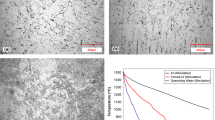

Austenite grain growth does not only play an important role in determining the mechanical properties of steel, but certain surface defects encountered in the continuous casting industry have also been attributed to the formation of large austenite grains. Earlier research has seen innovative experimentation, the development of metallographic techniques to determine austenite grain size and the building of mathematical models to simulate the conditions pertaining to austenite grain growth during the continuous casting of steel. Oscillation marks and depressions in the meniscus region of the continuously casting mold lead to retarded cooling of the strand surface, which in turn results in the formation of coarse austenite grains, but little is known about the mechanism and rate of formation of these large austenite grains. Relevant earlier research will be briefly reviewed to put into context our recent in situ observations of the delta-ferrite to austenite phase transition. We have confirmed earlier evidence that very large delta-ferrite grains are formed very quickly in the single-phase region and that these large delta-ferrite grains are transformed to large austenite grains at low cooling rates. At the higher cooling rates relevant to the early stages of the solidification of steel in a continuously cast mold, delta-ferrite transforms to austenite by an apparently massive type of transformation mechanism. Large austenite grains then form very quickly from this massive type of microstructure and on further cooling, austenite transforms to thin ferrite allotriomorphs on austenite grain boundaries, followed by Widmanstätten plate growth, with almost no regard to the cooling rate. This observation is important because it is now well established that the presence of a thin ferrite film on austenite grain boundaries is the main cause of reduction in hot ductility. Moreover, this reduction in ductility is exacerbated by the presence of large austenite grains.

Similar content being viewed by others

References

M. Militzer, A. Giumelli, E. B. Hawbolt and T. R. Meadowcroft: Metall Mater. Trans. A, vol. 27A, 1996, p. 3399.

E. S. Szekeres: Proceedings of the Sixth International Conference on Clean Steel, Balatonfüred, Hungary, 10–12 June 2002, OMBKE, Budapest.

V. Ludlow, A.W.A. Smith, A.S. Normanton, S. Landa, J. Wans, A. Gotti and M. Thiemann, 4 th European Continuously Casting Conference, Birmingham, U.K., (2002).

J. Marcisz, B. Garbarz and A. Zak: AISTech12, 6–9 May 2012, Atlanta GA.

D.N. Crowther and B. Mintz: Mater. Sci. Technol., vol. 2(9), 1986, p. 671.

L. Schmidt and A. Josefsson: Scand. J. Met., vol. 5, 1974, pp. 193–99

G. Alvarez de Toledo, A. Arteaga, and J. J. Laraudogoitia: Mater. Sci. Forum, Nov 2005, pp. 500–01.

H.T. Tsai, H. Yin, M. Morales and S. Morales: AISTech 05, AISTech, Charlotte, NC (2005).

S.-C. Moon: MEng Thesis, University of Wollongong, 2004.

R. Dippenaar, S.-C. Moon, and E.S. Szekeres: Iron & Steel Technol., July 2007.

B. Mintz, S. Yue and J.J. Jonas, Int. Mat. Rev., 36, 5, (1991),.

E.S. Szekeres: Iron Steel Eng., vol. 73(7), 1996, pp. 29–37.

J. Sengupta, B.G. Thomas, H-J. Shin, and S-H. Kim, Acta Materialia, 54, 4, (2006).

J. Sengupta, B.G. Thomas, H-J. Shin, and S-H Kim: AISTech, Proceedings, vol. 1, 2006.

C.M. Chimani and K. Mörwald, ISIJ Int. 39, 11, (1999).

C. Chimani, G. X. Shan, K. Mörwald, O. Kolednik, H. J. Böhm, D. Duschlbauer, and T. Drabek: AISTech Proc. vol. 1, May 1–4, 2006, Cleveland OH.

Y. Maehara, K. Yasumoto, H. Tomono, T. Nagamichi and Y. Ohmori, Mat. Sci. and Tech., 6, 9, (1990).

C. Bernhard, J. Reiter, and H. Preszlinger: Mater. Sci. Technol., MS&T’06, Cincinnati, OH, Oct 2006.

B. Mintz, ISIJ Int., 39, 9, (1999).

J. Miettinen, S. Louhenkilpi and L. Holappa: ISIJ Int., 36, 1996.

C. Bernhard, J. Reiter and H. Presslinger: Metall. Mater. Trans. B, 39B, 2008, pp. 885–95.

S. Niknafs: MEng Thesis, University of Wollongong, 2007.

Niknafs, S. & Dippenaar, R. J., Direct observation of high-temperature phase transformations in steel: delta-ferrite to austenite phase transformation”; Dr. Müller: Saarbrücken, (2009).

Z. Liu, Y. Kobayashi, J. Yang, K. Nagai and M. Kuwabara, ISIJInt., 46, 6, (2006).

H. Shibata, Y. Arai, M. Suzuki, and T. Emi: Metall. Mater. Trans. B, vol. 31B, 2000, p. 981.

N. Kikuchi, S. Nabeshima, Y. Kishimoto, J. Nakano and S. Seetharaman, ISIJInt., 48, 7, (2008).

C. Bernhard and T. Sjökvist: Berg- und Huettenm. Mon., vol. 151, 2006, p. 5.

Acknowledgments

One of the authors (Rian D) wishes to thank the University of Wollongong (Australia) for granting study leave that enabled him to collaborate with the other authors in Leoben. The authors wish to acknowledge the support of the University of Leoben (Austria) for the provision of laboratory facilities. Financial support by the Austrian Federal Government (in particular from the Bundesministerium für Verkehr, Innovation und Technologie and the Bundesministerium für Wirtschaft und Arbeit) and the Styrian Provincial Government, represented by Österreichische Forschungsförderungsgesellschaft mbH and by Steirische Wirtschaftsförderungsgesellschaft mbH, within the research activities of the K2 Competence Centre on “Integrated Research in Materials, Processing and Product Engineering,” operated by the Materials Center Leoben Forschung GmbH in the framework of the Austrian COMET Competence Centre Programme, is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted January 23, 2013.

Rights and permissions

About this article

Cite this article

Dippenaar, R., Bernhard, C., Schider, S. et al. Austenite Grain Growth and the Surface Quality of Continuously Cast Steel. Metall Mater Trans B 45, 409–418 (2014). https://doi.org/10.1007/s11663-013-9844-6

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-013-9844-6