Abstract

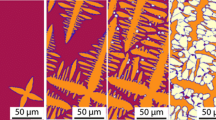

In order to achieve a fine uniform grain-size distribution using the process of thin slab casting and directing rolling (TSCDR), it is necessary to control the grain-size prior to the onset of thermomechanical processing. In the companion paper, Model Fe-Al Steel with Exceptional Resistance to High Temperature Coarsening. Part I: Coarsening Mechanism and Particle Pinning Effects, a new steel composition which uses a small volume fraction of austenite particles to pin the growth of delta-ferrite grains at high temperature was proposed and grain growth was studied in reheated samples. This paper will focus on the development of a simple laboratory-scale setup to simulate thin-slab casting of the newly developed steel and demonstrate the potential for grain size control under industrial conditions. Steel bars with different diameters are briefly dipped into the molten steel to create a shell of solidified material. These are then cooled down to room temperature at different cooling rates. During cooling, the austenite particles nucleate along the delta-ferrite grain boundaries and greatly retard grain growth. With decreasing temperature, more austenite particles precipitate, and grain growth can be completely arrested in the holding furnace. Additional applications of the model alloy are discussed including grain-size control in the heat affected zone in welds and grain-growth resistance at high temperature.

Similar content being viewed by others

References

C. Klinkenberg, C. Bilgen, J.M. Rodriguez-Ibabe, B. Lopez and P. Uranga: Mater. Sci. Forum, 2012, vols. 706-709, pp. 2752-57.

G. Arvedi, F. Mazzolari, J. Siegl, G. Hohenbichler and G. Holleis: Ironmaking and Steelmaking, 2010, vol. 37(4):271-75.

K. Hensger, L. Leduc Lezama, and F. Siciliano: 33rd McMaster Symposium on Iron & Steelmaking: Thinner Slab Casting, G.A. Irons, ed., McMaster University, Hamilton, 2005, pp. 262–76.

S.J. Cobo and C.M. Sellars: Ironmaking and Steelmaking. 2001, vol. 28(3), pp. 230-36.

P. Uranga, A.I. Fernández, B. López, and J.M. Rodriguez-Ibabe: Mater. Sci. Forum, 2005, vols. 500-501, pp. 245-52.

N.S. Pottore, C.I. Garcia, and A.J. DeArdo: Metall. Trans. A, 1991, vol. 22A, pp. 1871-80.

T. Gladman: The Physical Metallurgy of Microalloyed Steel, Institute of Materials, London, 1997, pp. 159-61.

Available from Thermo-calc Software: www.thermocalc.com. Accessed 7 Oct 2014.

T. Zhou, R.J. O’Malley and H.S. Zurob: Metall. Mater. Trans. A, 2010, vol. 41A, pp. 2112-20.

J.W. Martin, R.D. Doherty and B. Cantor: Stability of Microstructure in Metallic System, Cambridge University Press, Cambridge, 1997, pp. 219-31.

Y. Meng and B. G. Thomas: Metall. Mater. Trans. B, 2003, vol. 34B, pp. 685-705.

L.P. Zhang, C.L. Davis, and M. Strangwood: Metall. Mater. Trans. A, 1999, vol. 30A, pp. 2089–96.

F. Hamad, L. Collins, and R. Volkers: Proc. 7th Int. Pipeline Conf. (IPC2008), ASME, Calgary, 2008, IPC2008-64097.

R.A. Silva, G.Z. Batista, L.F.G. de Souza, and I.S. Bott: Mater. Sci. Forum, 2012, vols. 706-709, pp. 2059-65.

K. Banerjee, M. Militzer, M. Perez and X. Wang: Metall. Mater. Trans. A, 2010, vol. 41A, pp. 3161-72.

D. Turnbull: Trans. AIME, 1951, vol. 191, pp. 661-65.

T. Zhou and H.S. Zurob: Can. Metall. Q., 2011, vol. 50(4), pp. 389-95.

Acknowledgments

This work is supported by the McMaster University Steel Research Centre and the RIEM program. Professor G.R. Purdy and Mr. J. Thomson of McMaster University are gratefully acknowledged for valuable discussions. We also acknowledge with thanks technical support received from CANMET Materials Technology Lab (Ottawa, Canada) and Essar Steel Algoma Inc.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted May 10, 2014.

Rights and permissions

About this article

Cite this article

Zhou, T., Zhang, P., O’Malley, R.J. et al. Model Fe-Al Steel with Exceptional Resistance to High Temperature Coarsening. Part II: Experimental Validation and Applications. Metall Mater Trans A 46, 190–198 (2015). https://doi.org/10.1007/s11661-014-2612-7

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-014-2612-7