Abstract

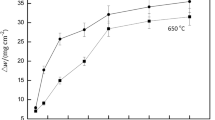

The effects of salt-bath nitriding time on the microstructure, microhardness, and erosion-corrosion behavior of nitrided 17-4PH stainless steel at 703 K (430 °C) were investigated by X-ray diffraction (XRD), scanning electron microscopy (SEM), transmission electron microscopy (TEM), and erosion-corrosion testing. The experimental results revealed that the microstructure and phase constituents of the nitrided surface alloy are highly process condition dependent. When 17-4PH stainless steel was subjected to complex salt-bathing nitriding, the main phase of the nitrided layer was expanded martensite (α`), expanded austenite (S), CrN, Fe4N, and Fe2N. The thickness of nitrided layers increased with the treating time. The salt-bath nitriding improves effectively the surface hardness. The maximum values measured from the treated surface are observed to be 1100 HV0.1 for 40 hours approximately, which is about 3.5 times as hard as the untreated material (309 HV0.1). Low-temperature nitriding can improve the erosion-corrosion resistance against two-phase flow. The sample nitrided for 4 hours has the best corrosion resistance.

Similar content being viewed by others

References

W. Jui-Hung and L. Chih-Kuang: J. Mater. Sci., 2003, vol. 38, pp. 965-71.

J. Wang, H. Zou, C. Li, S.-Yu. Qiu, and B.-L. Shen: Metall. Trans., 2005, vol. 46, pp. 846–51.

A. Leyland, D.B. Lewis, P.R. Stevenson, and A. Matthews: Surf. Coat. Technol., 1993, vol. 62, pp. 608-17.

F. Alonso, A. Arizaga, A. Garcia, and J.I. Onate: Surf. Coat. Technol., 1994, vol. 66, pp. 291-5.

B. Tesi, T. Bacci, and G. Poli: Vacuum, 1985, vol. 35, pp. 307-14.

Y. Sun, T. Bell, and G. Wood: Wear, 1994, vol. 178, pp. 131-8.

D. Manova, G. Thorwarth, S. Mandl, H. Neumann, B. Stritzker, and B. Rauschenbach: Nucl. Instr. Meth. B., 2006, vol. 242, pp. 285-8.

R.B. Frandsen, T. Christiansen, and M.A.J. Somers: Surf. Coat. Technol., 2006, vol. 200, pp. 5160-9.

Y. Sun and T. Bell: Surf. Eng., 2003, vol. 19, pp. 331-6.

H. Dong, M. Esfandiari, and X.Y. Li: Surf. Coat. Technol., 2008, vol. 202, pp. 2969–75.

H. Dong: Int. Mater. Rev., 2010, vol. 55, pp. 65-98.

P. Kochmański and J. Nowacki: Surf. Coat. Technol., 2006, vol. 200, pp. 6558-62.

K. Marusic, H. Otmacic, D. Landek, and F. Cajner: Surf. Coat. Technol., 2006, vol. 201, pp. 3415-21.

J. Wang, Y. Lin, Q. Zhang, J. Yan, D. Zen, R. Huang, and H. Fan: Surf. Coat. Technol., 2012, vol. 206, pp. 3399-404.

C.F. Yeung, K.H. Lau, H.Y. Li, and D.F. Luo: J. Mater. Process. Technol., 1997, vol. 66, pp. 249-52.

G. Li, J. Wang, Q. Peng, C. Li, Y. Wang, and B. Shen: J. Mater. Process. Technol., 2008, vol. 207, pp.187–92.

J.W. Zhang, L.T. Lu, K. Shiozawa, W.N. Zhou, and W.H. Zhang: Int. J. Fatigue, 2011, vol. 33, pp. 880-6.

K. Funatani: Met. Sci. Heat Treat., 2004, vol. 46, pp. 277–81.

J. Wang, Y. Lin, D. Zeng, J. Yan, and H. Fan: Metall. Mater. Trans. B, 2013, vol. 44B, pp. 414-22.

B. Larisch, U. Brusky, and H.J. Spies: Surf. Coat. Technol., 1999, vols. 116–119, pp. 205–11.

C.E. Foerster, F.C. Serbena, S.L.R. da Silva, C.M. Lepienski, C.J. deM. Siqueira, and M. Ueda: Nucl. Instr. Meth. B, 2007, vol. 257, pp. 732–36.

W. Jun, Y. Lin, H. Fan, D. Zen, P. Qian, and S. Baoluo: J. Mater. Eng. Perform., 2012, vol. 21, pp. 1708-13.

Z.L. Zhang and T. Bell: Surf. Eng., 1985, vol. 1, pp. 131-6.

J. Wang, J. Xiong, and T. Zhang: China Patent, No. ZL2011 10184878.1.

G. Dong, J. Xiong, M. Yang, Z. Guo, and W. Wan: Wear, 2012, vol. 294, pp. 364-9.

D. Hoeft, B.A. Latella, and K.T. Short: J. Phys.: Condens. Matter., 2005, vol. 17, pp. 3547-58.

D. Lopez, C. Sanchez, and A. Toro: Wear, 2005, vol. 258, pp. 684-92.

S.D. Chyou and H.C. Shih: Corrosion, 1991, vol. 47, pp. 31-4.

C.X. Li and T. Bell: Corros. Sci., 2004, vol. 46, pp. 1527-47.

E. Menthe and K.-T. Rie: Surf. Coat. Technol., 1999, vols. 116–119, pp. 199–24.

K.C. Chen, J.L. He, W.H. Huang, and T.T. Yeh: Wear, 2002, vol. 252, pp. 580-5.

Acknowledgments

The authors are very grateful to the National Natural Science Foundation of China (Grant No. 50901047) for financial support of this research work. The author (J.W) would like to thank Prof. Luo Defu of Xihua University, China for valuable discussions during the course of the research.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted December 18, 2012.

Rights and permissions

About this article

Cite this article

Wang, J., Lin, Y., Li, M. et al. Effects of the Treating Time on Microstructure and Erosion Corrosion Behavior of Salt-Bath-Nitrided 17-4PH Stainless Steel. Metall Mater Trans B 44, 1010–1016 (2013). https://doi.org/10.1007/s11663-013-9841-9

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-013-9841-9