Abstract

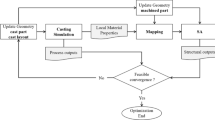

A methodology of how to exploit the Niyama criterion for the elimination of various defects such as centerline porosity, macrosegregation, and hot tearing in steel castings is presented. The tendency of forming centerline porosity is governed by the temperature distribution close to the end of the solidification interval, specifically by thermal gradients and cooling rates. The physics behind macrosegregation and hot tears indicate that these two defects also are dependent heavily on thermal gradients and pressure drop in the mushy zone. The objective of this work is to show that by optimizing the solidification pattern, i.e., establishing directional and progressive solidification with the help of the Niyama criterion, macrosegregation and hot tearing issues can be both minimized or eliminated entirely. An original casting layout was simulated using a transient three-dimensional (3-D) thermal fluid model incorporated in a commercial simulation software package to determine potential flaws and inadequacies. Based on the initial casting process assessment, multiobjective optimization of the solidification pattern of the considered steel part followed. That is, the multiobjective optimization problem of choosing the proper riser and chill designs has been investigated using genetic algorithms while simultaneously considering their impact on centerline porosity, the macrosegregation pattern, and primarily on hot tear formation.

Similar content being viewed by others

Notes

MAGMASOFT is a registered trademark of MAGMA GmbH, Aachen, Germany.

References

MAGMAsoft v.4.4 Reference Manual, MAGMA GmbH, Aachen, Germany, www.magmasoft.com.

P. Kotas, J.H. Hattel, J. Thorborg, I.L. Svensson, and S. Seifeddine: Proc. International Ph.D. Foundry Conference, Brno, Czech Republic, 2009.

S. Seifeddine, M. Wéssen, and I.L. Svensson: Metall. Sci. Technol., 2007, vol. 24, no. 2, p. 7.

J. Sturm, E. Hepp, and A. Enger-Walter: 20 th CAD-FEM Users` Meeting 2002, International Congress on FEM Technology, Lake Constance, Germany, 2002.

A. Egner-Walter: CP+T Casting Plant Tech. Int., 2007, vol. 23, no. 1, pp. 24–29.

D.R. Gunasageram, B.R. Finnin, and F.B. Polivka: Mater. Sci. Technol., 2007, vol. 23, no. 7, pp. 847–56.

K. Domkin, J.H. Hattel, and J. Thorborg: J. Mater. Process. Tech., 2009, vol. 209, no. 8, pp. 4051–61.

P. Kotas: Master’s Thesis, Technical University of Denmark, Lyngby, Denmark, 2007.

Z. Lin, C.A. Monroe, R.K. Huff, and C. Beckermann: Proc. Int. Conf. On Modelling of Casting, Welding and Advanced Solidification Processes, MCWASP XII, Vancouver, Canada, 2009, pp. 329–36.

V. Kokot and P. Bernbeck: Proc. Int. Conf. On Modelling of Casting, Welding and Advanced Solidification Processes, MCWASP X, Destin, FL, 2003, pp. 487–94.

MAGMAfrontier v.4.4 Reference Manual, MAGMA GmbH, Aachen, Germany, www.magmasoft.com, 2005.

I. Hahn and G. Hartmann: Cast. Plant Technol., 2008, vol. 24 (4), pp. 2–14.

I. Hahn and J.C. Sturm: Proc. World Foundry Congress, Hangzhou, China, 2010.

V.D. Tsoukalas: Proc. I Mech. E, 2008, vol. 222, pp. 1097–1106.

V.D. Tsoukalas: Mater. Des., 2008, vol. 29, pp. 2027–33.

N. Gramegna, P. Baumgartner, and V. Kokot: IDEAL International Conf., Lecce, Italy, 2005.

J. Campbell: Mater. Sci. Tech., 1988, vol. 4, pp. 194–204.

J.C. Simo and T.J.R. Hughes: Computational Inelasticity Series: Interdisciplinary Applied Mathematics, vol. 7, 1st ed., Springer, New York, NY, 1998.

J.H. Hattel: Fundamentals of Numerical Modelling of Casting Processes, 1st ed., Polyteknisk Forlag, Kgs. Lyngby, 2005.

W.S. Pellini: AFS Trans., 1953, vol. 61, pp. 61–80.

E. Niyama, T. Uchida, M. Morikawa, and S Saito: AFS Int. Cast. Met. J., 1982, vol. 7, no. 3, pp. 52–63.

J.A. Dantzig and M. Rappaz: Solidification, EPFL Press, Lausanne, Switzerland, 2009.

K.D. Carlson and C. Beckermann: Metall. Mater. Trans. A, 2009, vol. 40A, pp. 163–75.

K.D. Carlson, S. Ou, and C. Beckermann: Metall. Mater. Trans. B, 2005, vol. 36B, pp. 843–56.

R.A. Hardin, S. Ou, K.D. Carlson, and C. Beckermann: Metall. Mater. Trans. B, 2002, vol. 33B, pp. 731–40.

M.C. Schneider, J.P. Gu, C. Beckermann, W.J. Boettinger, and U.R. Kattner: Metall. Mater. Trans. A, 1997, vol. 28A, pp. 1517–31.

G.K. Sigworth and C. Wang: AFS Trans, 1992, vol. 100, pp. 989–1004.

C. Monroe and C. Beckermann: Mater. Sci. Eng. A, 2005, vols. 413–414, pp. 30–36.

C. Monroe: Ph.D. Dissertation, University of Iowa, Iowa City, IA, 2008.

U. Feurer: Giessereiforschung, 1976, vol. 28, no. 2, pp. 75–80.

I. Farup and A. Mo: Metall. Mater. Trans. A, 2000, vol. 31A, pp. 1461–72.

Y.M. Wong, H.N. Han, T. Yeo, and K.H. Oh: ISIJ Int., 2000, vol. 40, no. 2, pp. 129–36.

U.K. Bhattacharya, C.M. Adams, and H.F. Taylor: AFS Trans., 1952, vol. 60, p. 675.

D.G. Eskin and L. Katgerman: Metall. Mater. Trans. A, 2007, vol. 38A, pp. 1511–19.

D.E. Goldberg: Genetic Algorithms in Search, Optimization & Machine Learning, Addison Wesley Longmann, Inc., Boston, MA, 1989.

E. Zitzler: Ph.D. Dissertation, Swiss Federal Institute of Technology (ETH), Zurich, Switzerland, 1999.

S. Poles: MOGA-II: An improved Multi-Objective Genetic Algorithm. Technical Report; ESTECO s.r.l., 2003.

C.C. Tutum: Ph.D. Dissertation, Technical University of Denmark, Kongens Lyngby, Denmark, 2009.

K. Deb: Multi-Objective Optimization Using Evolutionary Algorithms, Wiley, New York, NY, 2001.

C.C. Tutum and J.H. Hattel: Sci. Technol. Weld. Joi., 2010, vol. 15, no. 5, pp. 369–77.

P. Kotas, C.C. Tutum, O. Snajdrova, J. Thorborg, and J.H. Hattel: Int. J. Met. Cast., 2010, vol. 4 (4).

P. Kotas, C.C. Tutum, S. Andersen, and J.H. Hattel: 115th Metalcasting Congress, Schaumburg, IL, 2011.

K. Deb: Eng. Optim., 2003, vol. 35, no. 5, pp. 445–70.

J. Kor, X. Chen, and H. Hu: IEEE International Symp. on Intelligent Control, Saint Petersburg, Russia, 2009.

I. Sobol: SIAM J. Numer. Anal., 1979, vol. 16, pp. 790–93.

J. Campbell: Castings Practice, The 10 Rules of Castings, Elsevier Butterworth-Heinemann, Atlanta, GA, 2004.

J. Campbell: Castings, Elsevier Butterworth-Heinemann, Atlanta, GA, 2003.

X. Dai, X. Yang, J. Campbell, and J. Wood: Mater. Sci. Technol., 2004, vol. 20, no. 4, pp. 505–13.

K. Miettinen: Nonlinear Multiobjective Optimization, Kluwer Academic Publishers, Boston, MA, 1999.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted April 13, 2011.

Rights and permissions

About this article

Cite this article

Kotas, P., Tutum, C.C., Thorborg, J. et al. Elimination of Hot Tears in Steel Castings by Means of Solidification Pattern Optimization. Metall Mater Trans B 43, 609–626 (2012). https://doi.org/10.1007/s11663-011-9617-z

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-011-9617-z