Abstract

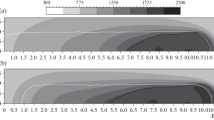

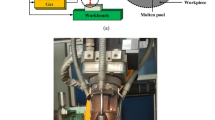

A multiscale model is developed in this article to investigate the transport phenomena and dendrite growth in the diode-laser-cladding process. A transient model with an improved level-set method is built to simulate the heat/mass transport and the dynamic evolution of the molten pool surface on the macroscale. A novel model integrating the cellular automata (CA) and phase field (PF) methods is used to simulate the dendritic growth of multicomponent alloys in the mushy zone. The multiscale model is validated against the experiments, and the predicted geometry of clad tracks and the predicted dendrite arm spacing of microstructure match reasonably well with the experimental results. The effects of the processing parameters on the track geometry and microstructure are also investigated.

Similar content being viewed by others

References

L. Costa, R. Vilar, T. Reti, and A.M. Deus: Acta Mater., 2005, vol. 53, pp. 3987-99.

L. Wang and S. Felicelli: J. Manuf. Sci. Eng.-Trans. ASME, 2007, vol. 129, pp. 1028-34.

B. Zheng, Y. Zhou, J.E. Smugeresky, J.M. Schoenung, and E.J. Lavernia: Metall. Mater. Trans. A, 2008, vol. 39A, pp. 2228-36.

S. Kumar, S. Roy, C.P. Paul, and A.K. Nath: Numer. Heat Tran. B, 2008, vol. 53, pp. 271-87.

P. Peyre, P. Aubry, R. Fabbro, R. Neveu, and A. Longuet: J. Phys. D, 2008, vol. 41, 025403.

L. Han, F.W. Liou, and K.M. Phatak: Metall. Mater. Trans. B, 2004, vol. 35B, pp. 1139-50.

J. Choi, L. Han, and Y. Hua: J. Heat Transfer-Trans. ASME, 2005, vol. 127, pp. 978-86.

H.O. Zhang, F.R. Kong, G.L. Wang, and L.F. Zeng: J. Appl. Phys., 2006, vol. 100, pp. 123522.

H. Qi, J. Mazumder, and H. Ki: J. Appl. Phys., 2006, vol. 100, pp. 024903.

X. He and J. Mazumder: J. Appl. Phys., 2007, vol. 101, pp. 053113.

S. Wen and Y.C. Shin: J. Appl. Phys., 2010, vol. 108, pp. 044908.

S. Wen and Y.C. Shin: J. Heat Transfer-Trans. ASME, 2011, vol. 133, pp. 031007.

A.F.A. Hoadley and M. Rappaz: Metall. Trans. B, 1992, vol. 23B, pp. 631-42.

S. Ghosh and J. Choi: J. Manuf. Sci. Eng.-Trans. ASME, 2007, vol. 129, pp. 319-32.

Z. Yang, S. Sista, J.W. Elmer, and T. DebRoy: Acta Mater., 2000, vol. 48, pp. 4813-25.

T. Koseki, H. Inoue, Y. Fukuda, and A. Nogami: Sci. Technol. Adv. Mater., 2003, vol. 4, pp. 183-95.

V. Pavlyk and U. Dilthey: Model. Simulat. Mater. Sci. Eng., 2004, vol. 12, pp. S33-45.

X.H. Zhan, Z.B. Dong, Y.H. Wei,and R. Ma: J. Cryst. Growth, 2009, vol. 311, pp. 4778-83.

H. Yin and S.D. Felicelli: Acta Mater., 2010, vol. 58, pp. 1455-65.

Y. Cao and J. Choi: J. Heat Transfer-Trans. ASME, 2007, vol. 129, pp. 852-63.

A. Farzadi, M. Do-Quang, S. Serajzadeh, A. Kokabi, and G. Amberg: Model. Simulat. Mater. Sci. Eng., 2008, vol. 16, pp. 065005.

B. Böttger, M. Apel, J. Eiken, P. Schaffnit, and I. Steinbach: Steel Res. Int., 2008, vol. 79, pp. 608-16.

W. Tan, N.S. Bailey, and Y.C. Shin: Comp. Mater. Sci., 2011, vol. 50 (9), pp. 2573–85.

W. Wang, P.D. Lee, and M. McLean: Acta Mater., 2003, vol. 51, pp. 2971-87.

S.G. Kim, W.T. Kim, and T. Suzuki: Phys. Rev. E, 1999, vol. 60, pp. 7186-97.

P.R. Cha, D.H. Yeon, and J.K. Yoon: J. Cryst. Growth, 2005, vol. 274, pp. 281-93.

R. Zhang, T. Jing, W. Jie, and B. Liu: Acta Mater., 2006, vol. 54, pp. 2235-39.

X. He, P.W. Fuerschbach, and T. DebRoy: J. Phys. D, 2003, vol. 36, pp. 1388-98.

W. Tan, N.S. Bailey, and Y.C. Shin: ASME Int. Conf. Manuf. Sci. Eng., 2011, pp. 50219.

W. Löser and D.M. Herlach: Metall. Trans. A, 1992, vol. 23A, pp. 1585-91.

S.G. Kim and W.T. Kim: Mater. Sci. Eng. A, 2001, vols. 304–306, pp. 281-86.

J. Miettinen: CALPHAD, 1999, vol. 23, pp. 231-48.

J. Miettinen: Metall. Mater. Trans. B, 2000, vol. 31B, pp. 365-79.

B. Zheng, Y. Zhou, J.E. Smugeresky, J.M. Schoenung, and E.J. Lavernia: Metall. Mater. Trans. A, 2008, vol. 39A, pp. 2237-45.

J. Choi and Y. Chang: Int. J. Mach. Tool. Manufact., 2005, vol. 45, pp. 597-607.

D.R. Poirier and J.C. Heinrich: Mater. Charact., 1994, vol. 32, pp. 287-98.

C. Beckermann, J.P. Gu, and W.J. Boettinger: Metall. Mater. Trans. A, 2000, vol. 31A, pp. 2545-57.

S.N. Tewari and R. Tiwari: Metall. Mater. Trans. A, 2003, vol. 34A, pp. 2365-76.

P.A. Kobryn, E.H. Moore, and S.L. Semiatin: Scripta Mater., 2000, vol. 43, pp. 299-305.

S. Katayama and A. Matsunawa: Proc. ICALEO, 1984, pp. 60–67.

J. Song, Q. Deng, C. Chen, D. Hu, and Y. Li: Appl. Surf. Sci., 2006, vol. 252, pp. 7934-40.

Acknowledgments

The authors wish to acknowledge gratefully the financial support provided for this study by the National Science Foundation (grants 0538786-IIP and 0917936-IIP), the State of Indiana through the 21st Century R&T Fund, and Industrial Consortium members of the Center for Laser-based Manufacturing. The authors also wish to thank Mr. Kevin Schoeffel for the help in the experiment.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted March 16, 2011.

Rights and permissions

About this article

Cite this article

Tan, W., Wen, S., Bailey, N. et al. Multiscale Modeling of Transport Phenomena and Dendritic Growth in Laser Cladding Processes. Metall Mater Trans B 42, 1306–1318 (2011). https://doi.org/10.1007/s11663-011-9545-y

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-011-9545-y