Abstract

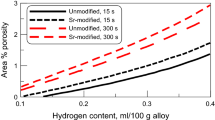

The mechanical properties of cast aluminum alloys can be affected by the delay in time involved between the stages of rapid cooling after solubilization (quenching) and aging. This effect was studied on samples from three different Al-Si alloys that were cast with a wide range of microstructures. It was found that the parameter that exerts the highest influence on the mechanical properties is the degree of microstructural refining, which is referred to dendrite arm spacing, as a finer structure enhances the strength and ductility. It was found that the yield strength and total elongation, and to a lesser extend the ultimate tensile strength, are affected by the delay in time. The material that was treated to the peak-aged condition was found to be more susceptible to the reduction in mechanical properties with the increase in the delay in time.

Similar content being viewed by others

References

J.B. Heywood: Internal Combustion Engine Fundamentals, McGraw-Hill, New York, NY, 1989.

P.M. Norris, M.C. Hastings, and W.J. Wepfer: J. Exp. Heat Trans., 1994, vol. 7, pp. 43-51.

I.J. Polmear: Light Alloys, Metallurgy of the Light Metals, Arnold, London, U.K., 1980.

J.W. Martin (1980) Micromechanisms in Particle Hardened Alloys, Cambridge University Press. Cambridge, U.K.

C.R. Brooks (1982) Heat Treatment, Structure and Properties of Nonferrous Alloys, ASM, Materials Park. OH.

J. Campbell: Castings, 2nd ed., Butterworth-Heinemann, Oxford, U.K., 2003.

R. Colás, E. Velasco, and S. Valtierra: in Handbook of Aluminum, Vol. 1: Physical Metallurgy and Processes, G.E. Totten and D.S. MacKenzie, eds., Marcel Dekker, New York, NY, 2003, pp. 591–641.

E. Sjölander and S. Seifeddine: J. Mater. Process. Tech., 2010, vol. 210, pp. 1249-59.

S. Das and U. Chandra: in Residual Stress and Distortion, Handbook of Aluminum, Vol. 1: Physical Metallurgy and Processes, G.E. Totten and D.S. MacKenzie, eds., Marcel Dekker, New York, NY, 2003, pp. 305–49.

A.I. García-Celis, E. Velasco, S. Valtierra, J.F. Mojica, and R. Colás: Automotive Alloys II, S. Das, ed., TMS, Warrendale, PA, 1998, pp. 135–43.

J.L. Cavazos and R. Colás: J. Mater. Eng. Perform., 1999, vol. 8, pp. 509-12.

J.L. Cavazos and R. Colás: Mater. Charact., 2001, vol. 47, pp. 175-79.

B. Xiao, Q. Qang, P. Jadhav, and K. Li: J. Mater Process. Tech., 2010, vol. 210, pp. 2023-28.

B. Xiao, Y. Ront, Q. Wang, G. Wang, M. Maniruzzaman, and R.D. Sisson: J. Mater. Eng. Perform., 2010, vol. 210, pp. 2023–2208.

F.J. Tavitas-Moreno, J.E. Gurzleski, F.H. Samuel, S. Valtierra, and H.W. Doty: Mater. Sci. Eng. A, 2008, vol. A480, pp. 356-68.

Z. Ma, A.M. Samuel, F.H. Samuel, H.W. Doty, and S. Valtierra: Mater. Sci. Eng. A, 2008, vol. A490, pp. 36-51.

L. Bäckerud, G. Chai, and J. Tamminen: Solidification Characteristics of Aluminum Alloys, Vol. 2: Foundry Alloys, AFS, Des Plains, IL, 1990.

L. Arnbert, L. Bäckerud, and G. Chai: Solidification Characteristics of Aluminum Alloys, Vol. 3: Dendritic Coherency, AFS, Des Plains, IL, 1996.

R. Colás, A. Rodríguez, J. Talamantes, and S. Valtierra: Int. J. Cast Metal. Res., 2004, vol. 17, pp. 332-38.

R. Torres, J. Esparza, E. Velasco, S. García-Luna, and R. Colás: Int. J. Microstruct. Mater. Prop., 2006, vol. 1, pp. 129-38.

ASTM B557M-94, Standard Test Methods of Tension Testing Wrought and Cast Aluminum and Magnesium Alloy Products (Metric), ASTM International, West Conshohocken, PA, 1994.

ASTM E8M-99, Standard Test Methods for Tension Testing of Metallic Materials (Metric), ASTM International, West Conshohocken, PA, 1999.

T. Din, A.K.M.B. Rashid, and J. Campbell: Mater. Sci. Technol., 1996, vol. 12, pp. 269-75.

C.H. Caceres, T. Din, A.K.M.B. Rashid, and J. Campbell: Mater. Sci. Technol., 1999, vol. 12, pp. 711-16.

C.H. Caceres: J. Mater. Eng. Perform., 2000, vol. 9, pp. 215-21.

C.H. Caceres, M. Makhlouf, D. Apelian, and L. Wang: J. Light Met., 2001, vol. 1, pp. 51-59.

N.D. Alexopoulos and S.G. Pantelakis: Metall. Mater. Trans. A, 2004, vol. 35A, pp. 301-08.

Z. Li, A.M. Samuel, F.H. Samuel, C. Ravindran, H.W. Doty, and S. Valtierra: Mater. Sci. Eng. A, 2004, vol. 367, pp. 96-110.

Z. Li, A.M. Samuel, F.H. Samuel, C. Ravindran, H.W. Doty, and S. Valtierra: Mater. Sci. Eng. A, 2004, vol. 367, pp. 111-22.

J.A. Taylor, D.H. St. John, J. Barresi, and M.J. Cooper: Int. J. Cast Metal. Res., 2000, vol. 12, pp. 277-82.

Z. Li, A.M. Samuel, F.H. Ravindran, and S. Valtierra: J. Mater. Sci., 2003, vol. 38, pp. 1203-18.

Y.M. Han, A.M. Samuel, F.H. Samuel, S. Valtierra, and H.W. Doty: AFS Trans., 2008, vol. 116, pp. 79-90.

E. Sjölander and S. Seifeddine: Mater. Des., 2010, vol. 31, pp. 544-49.

A.A. Canales, J. Talamantes-Silva, D. Gloria, S. Valtierra, and R. Colás: Thermochim. Acta, 2010, vol. 510, pp. 82-87.

J.A. Taylor, D.H. St. John, J. Barresi, and M.J. Couper: Mater. Sci. Forum, 2000, vols. 331–337, pp. 277-82.

H- Möller, G. Govender, and W.E. Stump: Int. J. Cast. Metal. Res., 2007, vol. 20, pp. 340–46.

A. Cuniberti, A. Tolley, M.V. Castro Riglos, and R. Giovachini: Mater. Sci. Eng. A, 2010, vol. 537, pp. 5307-11.

G.A. Edwards, K. Stiller, G.L. Dunlop, and M.J. Couper: Acta Mater., 1998, vol. 46, pp. 3893-3904.

M. Murayama and K. Hono: Acta Mater., 1999, vol. 47, pp. 1537-48.

P.A. Rometsch and G.B. Schaffer: Mater. Sci. Eng. A, 2002, vol. 325, pp. 424-34.

N.D. Alexopoulos and S.G. Pantelakis: Mater. Des., 2004, vol. 25, pp. 419-20.

W. Reif, S. Yu, J. Dutkiewicz, R. Ciach, and J. Król: Mater. Des., 1997, vol. 18, pp. 253-56.

M. Drouzy, S. Jacob, and M. Richard: AFS Int. Cast. Met. J., 1980, vol. 5, pp. 43-50.

N.D. Alexopoulos: J. Mater. Eng. Perform., 2006, vol. 15, pp. 59-66.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted December 28, 2010.

Rights and permissions

About this article

Cite this article

Carrera, E., Alejandro González, J., Talamantes-Silva, J. et al. Effect of the Delay in Time Between Cooling and Aging in Heat-Treated Cast Aluminum Alloys. Metall Mater Trans B 42, 1023–1030 (2011). https://doi.org/10.1007/s11663-011-9534-1

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-011-9534-1