Abstract

In the current study, a new artificial aging process, Retrogression and re-aging (RRA), which is a multi-step precipitation hardening, was utilized to investigate its effect on microstructure and mechanical properties of Al2024 alloys and compare the results with conventional T6. The microstructural evolution during heat treatment was studied by SEM and TEM, and tension test and hardness test were used to investigate the mechanical properties of specimens. The results showed that RRA process has improved the mechanical properties of Al2024 in comparison with T6. Yield stress, UTS, elongations and brinell hardness in RRA samples are higher than T6. The microstructural investigation revealed that during RRA, more secondary particles solute in matrix and more and finer S and θ phase precipitate. It was also observed that in RRA samples, S and θ phases have better distribution in Al matrix.

Similar content being viewed by others

References

A. Staszczyk, J. Sawicki and B. Adamczyk-Cieslak, A Study of Second-Phase Precipitates and Dispersoid Particles in 2024 Aluminum Alloy After Different Aging Treatments, Materials, 2019, 12(24), p 4168. https://doi.org/10.3390/ma1224168

D.A.P. Reis, A.A. Couto, N.I. Domingues, A.C.O. Hirschmann, S. Zepka and C. Moura Neto, Effect of Artificial Aging on the Mechanical Properties of an Aerospace Aluminum Alloy 2024, Defect Diffus Forum, 2012, 326, p 193–198. https://doi.org/10.4028/www.scientific.net/DDF.326-328.193

S. Lipa, Ł Kaczmarek, M. Stegliński, H. Radziszewska, K. Kyzioł and D. Kottfer, Effect of Core/Shell Precipitations on Fatigue Strength of 2024-T6i6 Alloy, Int. J. Fatigue., 2019, 127, p 165–174. https://doi.org/10.1016/j.ijfatigue.2019.06.006

G. Xiao, B. Chen, S. Li and X. Zhuo, Fatigue Life Analysis of Aero-Engine Blades for Abrasive Belt Grinding Considering Residual Stress, Eng. Fail. Anal., 2022, 131, p 105846. https://doi.org/10.1016/j.engfailanal.2021.105846

Z.M. Liang, G.Y. Wang, Z. Bin Sun, D.L. Wang, L.W. Wang and Y.M. Liang, Rapidly Improved Tensile Strength of 6n01 Al Alloy Fsw Joints By Electropulsing and Artificial Aging Treatment, Mater. Sci. Eng. A, 2022, 841, p 143056. https://doi.org/10.1016/j.msea.2022.143056

Y. Xie, X. Meng, F. Wang, Y. Jiang, X. Ma, L. Wan and Y. Huang, Insight on Corrosion Behavior of Friction Stir Welded Aa2219/Aa2195 Joints in Astronautical Engineering, Corros. Sci., 2021, 192, p 109800. https://doi.org/10.1016/j.corsci.2021.109800

K.B. Demétrio, A.P.G. Nogueira, C. Menapace, T. Bendo and A. Molinari, Effect of Nanostructure on Phase Transformations during Heat Treatment of 2024 Aluminum Alloy, J. Mater. Res. Technol., 2021, 14, p 1800–1808. https://doi.org/10.1016/j.jmrt.2021.07.044

C.K.S. Moy, M. Weiss, J. Xia, G. Sha, S.P. Ringer and G. Ranzi, Influence of Heat Treatment on the Microstructure, Texture and Formability of 2024 Aluminium Alloy, Mater. Sci. Eng. A, 2012, 552, p 48–60. https://doi.org/10.1016/j.msea.2012.04.113

T.J. Bastow and A.J. Hill, Guinier-Preston and Guinier-Preston-Bagaryatsky Zone Reversion in Al-Cu-Mg Alloys Studied By Nmr, Mater. Sci. Forum., 2006, 519–521, p 1385–1390. https://doi.org/10.4028/www.scientific.net/msf.519-521.1385

H. Wang, J. Xie, Y. Chen, W. Liu and W. Zhong, Effect of Cocrfenimn High Entropy Alloy Interlayer on Microstructure and Mechanical Properties of Laser-Welded Niti/304 Ss Joint, J. Mater. Res. Technol., 2022, 18, p 1028–1037. https://doi.org/10.1016/j.jmrt.2022.03.022

L. Liang, M. Xu, Y. Chen, T. Zhang, W. Tong, H. Liu, H. Wang and H. Li, Effect of Welding Thermal Treatment on the Microstructure and Mechanical Properties of Nickel-Based Superalloy Fabricated By Selective Laser Melting, Mater. Sci. Eng. A, 2021, 819, p 141507. https://doi.org/10.1016/j.msea.2021.141507

S.C. Wang and M.J. Starink, Two Types of S Phase Precipitates in Al-Cu-Mg Alloys, Acta Mater., 2007, 55, p 933–941. https://doi.org/10.1016/j.actamat.2006.09.015

Y. Zhong, J. Xie, Y. Chen, L. Yin, P. He and W. Lu, Microstructure and Mechanical Properties of Micro Laser Welding NiTiNb/Ti6Al4V Dissimilar Alloys Lap Joints with Nickel Interlayer, Mater. Lett., 2022, 306, p 130896. https://doi.org/10.1016/j.matlet.2021.130896

L. Sun, Y. Guo, L. Chen and G. Zhao, Effects of Solution and Aging Treatments on the Microstructure and Mechanical Properties of Cold Rolled 2024 Al Alloy Sheet, J. Mater. Res. Technol., 2021, 12, p 1126–1142. https://doi.org/10.1016/j.jmrt.2021.03.051

Y. Zhao, Stability of Phase Boundary Between L12-Ni3Al Phases: A Phase Field Study, Intermetallics, 2022, 144, p 107528. https://doi.org/10.1016/j.intermet.2022.107528

Y. Zhao, K. Liu, H. Hou and L.-Q. Chen, Role of Interfacial Energy Anisotropy in Dendrite Orientation in Al-Zn Alloys: A phase Field Study, Mater. Des., 2022, 216, p 110555. https://doi.org/10.1016/j.matdes.2022.110555

M. Emamy, M. Oliayee and K. Tavighi, Author ’s Accepted Manuscript, Mater. Sci. Eng. A, 2014 https://doi.org/10.1016/j.msea.2014.12.023

N.D. Alexopoulos, Z. Velonaki, C.I. Stergiou and S.K. Kourkoulis, The Effect of Artificial Ageing Heat Treatments on the Corrosion-Induced Hydrogen Embrittlement of 2024 (Al-Cu) aluminium alloy, Corros. Sci., 2016, 102, p 413–424. https://doi.org/10.1016/j.corsci.2015.10.034

M.S. Nandana, K. Udaya Bhat and C.M. Manjunatha, Effect of Retrogression and Re-ageing Heat Treatment on Microstructure and Microhardness of Aluminium 7010 Alloy, MATEC Web Conf., 2018 https://doi.org/10.1051/matecconf/201714402003

R. Gürbüz, N. Akgün, Efect of retrogression and re-aging heat treatment on the corrosion fatigue crack growth behavior of AA7050 aluminum alloy. In: 11th Int. Conf. Fract. 2005, ICF11. 1 (2005) 95

S.V. Emani, J. Benedyk, P. Nash and D. Chen, Double Aging and Thermomechanical Heat Treatment of AA7075 Aluminum Alloy Extrusions, J. Mater. Sci., 2009, 44, p 6384–6391. https://doi.org/10.1007/s10853-009-3879-8

X. Li, H. Wang, T. Shi, C. Zhang, X. Jiang, X. Zhou and C. Li, Efficient Preparation and Anticorrosion Mechanism of Superhydrophobic 7075 Aviation Aluminum Alloy, Xiyou Jinshu Cailiao Yu Gongcheng/Rare Met, Mater. Eng., 2022, 51, p 6–10.

Y. Xu, H. Zhang, F. Yang, L. Tong, D. Yan, Y. Yang, Y. Wang and Y. Wu, Experimental Investigation of Pneumatic Motor for transport Application, Renew. Energy, 2021, 179, p 517–527. https://doi.org/10.1016/j.renene.2021.07.072

B. Cina, (1974), https://patents.google.com/patent/US3856584A/en. Reducing the Susceptibility of Alloys, Particularly Aluminium Alloys, to Stress Corrosion Cracking

J.F. Li, Z.W. Peng, C.X. Li, Z.Q. Jia, W.J. Chen and Z.Q. Zheng, Mechanical Properties, Corrosion Behaviors and Microstructures of 7075 Aluminium Alloy with Various Aging Treatments, Trans. Nonferrous Met. Soc. China, 2008, 18, p 755–762. https://doi.org/10.1016/S1003-6326(08)60130-2

Z. Wu, S. Wu, J. Bao, W. Qian, S. Karabal, W. Sun and P.J. Withers, The Effect of Defect Population on the Anisotropic Fatigue Resistance of AlSi10Mg Alloy Fabricated by Laser Powder Bed Fusion, Int. J. Fatigue., 2021, 151, p 106317. https://doi.org/10.1016/j.ijfatigue.2021.106317

X. Li, X. Yang, D. Yi, B. Liu, J. Zhu, J. Li, C. Gao and L. Wang, Effects of NbC Content on Microstructural Evolution and Mechanical Properties of Laser Cladded Fe50Mn30Co10Cr10-xNbC Composite Coatings, Intermetallics, 2021, 138, p 107309. https://doi.org/10.1016/j.intermet.2021.107309

X. Li, D. Yi, X. Wu, J. Zhang, X. Yang, Z. Zhao, Y. Feng, J. Wang, P. Bai, B. Liu and Y. Liu, Effect of Construction Angles on Microstructure and Mechanical Properties of AlSi10Mg Alloy Fabricated by Selective Laser Melting, J. Alloys Compd., 2021, 881, p 160459. https://doi.org/10.1016/j.jallcom.2021.160459

S. Pournazari, K.M. Deen, D.M. Maijer and E. Asselin, Effect of Retrogression and Re-aging (RRA) Heat Treatment on the Corrosion Behavior of B206 Aluminum-Copper Casting Alloy, Mater. Corros., 2018, 69, p 998–1015. https://doi.org/10.1002/maco.201709925

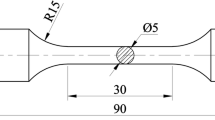

I. ASTM, ASTM E8/E8M Standard Test Methods For Tension Testing of Metallic Materials, ASTM Int, 2010 https://doi.org/10.1520/E0008

I. Standard, (2003) International Standard Metallic Materials Sheet and Strip

Z.Q. Feng, Y.Q. Yang, B. Huang, M.H. Li, Y.X. Chen and J.G. Ru, Crystal Substructures of the Rotation-Twinned T (Al20Cu 2Mn3) Phase in 2024 Aluminum Alloy, J. Alloys Compd., 2014, 583, p 445–451. https://doi.org/10.1016/j.jallcom.2013.08.200

S. Krymskiy, O. Sitdikov, E. Avtokratova and M. Markushev, 2024 Aluminum Alloy Ultrahigh-Strength Sheet Due to Two-Level Nanostructuring Under Cryorolling and Heat Treatment, Trans. Nonferrous Met. Soc. China, 2020, 30, p 14–26. https://doi.org/10.1016/S1003-6326(19)65176-9

Acknowledgments

This work was supported by Scientific Research Project of Hunan Provincial Department of Education (design and analysis of assembled frictional energy dissipation composite wallboard 20C0850); Yongzhou Guided Science and Technology Project (research on key technologies for BIM-based modular structure design and construction 2019-yzkj-17); National Natural Science Foundation of China in No. 51808247; Huaiyin Institute of Technology Laboratory Open Fund in No. JSZP201902; The Natural Science Foundation of the Jiangsu Higher Education Institutions of China in No. 18KJB560003.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Guo, E., Gao, Y., Ye, T. et al. Investigation on the Effect of Retrogression and Re-aging on Microstructure and Mechanical Properties of 2024 Aluminum Alloys. J. of Materi Eng and Perform 32, 728–734 (2023). https://doi.org/10.1007/s11665-022-07141-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-07141-4