Abstract

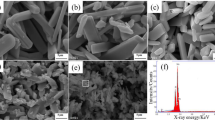

The molybdenum powder with crystalline icositetrahedron morphology was produced by hydrogen reduction of MoO3. The particle size and morphology of MoO3 were specified to control the reaction rate. The phase change and microstructure during the MoO3-MoO2 reduction were highlighted to obtain MoO2, which tended to form polyhedral Mo powder. Reduction conditions such as temperature profile, hydrogen dew point, and flow rate were optimized systematically to favor the nucleation and growth of new phases. The molybdenum powder thereof was sintered with conventional method, and the microstructure of the post-sinter plate was determined. The density of 10.15 g/cm3 was achieved. The mechanism of the polyhedral powder formation and the sintering performance of 99 pct theoretical density were discussed.

Similar content being viewed by others

References

G.P. Martins, T. Kangsadan, G. Scott, C. Wagner, and J. Van Hoose: Mater. Sci. Forum, 2007, vols. 561–565, pp. 447-52.

Z. Jun, L.Z. Zhong, L.Y. Min, and W.Z. Wei: China Molybd. Ind., 2006, vol. 30, no 3, pp. 36-39.

G.L. Messing and A.J. Stevence: Science, 2008, vol. 322, no. 5990, pp. 383-84.

J.L. Garrin and R.L. Mannheim: Key Eng. Mater., 2001, vols. 181–191, pp. 232-38.

T. Leisegang, A.A. Levin, J. Walter, and D.C. Meyer: Cryst. Res. Technol., 2005, vol. 40, no.1–2, pp. 95-105.

T. Ressler, J. Wienold, R.E. Jentoft, and T. Neisius: J. Catal., 2002, vol. 210, pp. 67-83.

Y. Fenglin: Int. J. Refract. Met. Hard Mater., 2004, vol. 22, no. 1, pp. 57-60.

J. Orehotskya and M. Kaczenskia: Mater. Sci. Eng., 1979, vol. 40 (2), pp. 245-50.

W. Schulmeyler and H. Ortner: Int. J. Refract. Metall. Hard Mater., 2002, vol. 20, pp. 261-69.

S. Majumdar, I.G. Sharma, I. Samajdar, and P. Bhargava: Metall. Mater. Trans. B, 2008, vol. 39B, pp. 431-38.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted July 24, 2009.

Rights and permissions

About this article

Cite this article

Wang, X., Liu, J., Zhuang, F. et al. The Formation of Icositetrahedron Molybdenum Powder and the Characteristics of Sintering Performance. Metall Mater Trans B 41, 1067–1073 (2010). https://doi.org/10.1007/s11663-010-9409-x

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-010-9409-x