Abstract

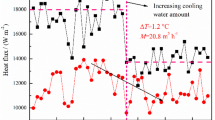

The direct current (DC) furnace, the earliest type of the electric arc furnace (EAF), was popularized at the end of the 1980s. Even in its heyday, there were always doubts about its superiority due to some imperfections of the DC furnace (e.g., the problems of the bottom electrode system). The water-cooled billet electrode, which is classified as one of the four types of the bottom electrodes, has been in use for more than two decades. However, so far its melting mechanism has not been well understood. A sophisticated numerical model was thus constructed by coupling the heat transfer and the fluid flow, and taking into account the electromagnetic effect as well as the influence of the gap between the billet and the copper jacket. The observed phenomena could readily be explained using the model. The computed results show that the axial component of the electromagnetic force plays an essential role in driving the strong flow within the electrode hole, and that the Joule effect does not contribute the majority of the heat taken away by cooling water. An important conclusion is reached that there is a double-edged effect by changing the billet diameter. Accordingly, a modification of the billet shape is suggested, i.e., a diameter-variable structure, which should greatly assist in improving the thermal state of the billet.

Similar content being viewed by others

Abbreviations

- C p :

-

specific heat (J·kg−1·K−1)

- C pl :

-

specific heat of liquid steel (J·kg−1·K−1)

- C ps :

-

specific heat of solid steel (J·kg−1·K−1)

- D :

-

diameter of the steel billet (m)

- f l :

-

mass fraction of liquid steel

- f s :

-

mass fraction of solid steel

- F r :

-

radial component of the body force (N)

- F z :

-

axial component of the body force (N)

- F B–S :

-

Biot–Savart force

- \( F_r^{B - S} \) :

-

radial component of F B–S (N)

- \( F_z^{B - S} \) :

-

axial component of F B–S (N)

- g :

-

acceleration of gravity (m·s−2)

- h :

-

heat-transfer coefficient (W·m−2·K−1)

- h air :

-

environmental heat-transfer coefficient at boundary B4 (W·m−2·K−1)

- h e :

-

equivalent heat-transfer coefficient at boundary B5 (W·m−2·K−1)

- H :

-

enthalpy of the two-phase mixture (J·kg−1)

- H l :

-

enthalpy of liquid steel (J·kg−1)

- H s :

-

enthalpy of solid steel (J·kg−1)

- I :

-

electric current through a steel billet (A)

- m :

-

multiplier used to estimate the equivalent thermal conductivity of liquid steel

- p :

-

pressure (Pa)

- Q average :

-

average heat flux from the billet to the copper jacket (W·m−2)

- ΔQ water :

-

total heat taken away by the cooling water (W)

- r :

-

radial coordinate (m)

- R :

-

radius of the steel billet (m)

- S :

-

inner heat resource (W·m−3)

- T :

-

temperature (K)

- T air :

-

environmental temperature at boundary B4 (K)

- T billet :

-

temperature of the billet at boundary B5 (K)

- T copper :

-

temperature of the copper jacket at boundary B5 (K)

- T furnace :

-

temperature of furnace shell at boundary B4 (K)

- T m :

-

temperature of solid-liquid phase transformation of the steel billet (K)

- T max :

-

maximal temperature in the electrode hole (K)

- ΔT water :

-

inlet-outlet temperature difference of the cooling water (°C)

- v :

-

velocity vector of the flow

- v r :

-

radial component of v (m·s−1)

- v z :

-

axial component of v (m·s−1)

- V max :

-

maximal magnitude of the flow velocity in the electrode hole (m·s−1)

- z :

-

axial coordinate (m)

- Z liquidus :

-

position of the liquidus (m)

- α:

-

expanding angle of the electrode hole

- β:

-

volume expansion coefficient of liquid steel (K−1)

- δ :

-

space of the gap between the billet and the copper jacket (mm)

- ε shell :

-

emissivity of the furnace shell

- η :

-

viscosity (Pa·s)

- η sl :

-

equivalent viscosity in mush region (Pa·s)

- η l :

-

viscosity of liquid steel (Pa·s)

- λ :

-

thermal conductivity (W·m−1·K−1)

- λ e :

-

equivalent thermal conductivity of liquid steel (W·m−1·K−1)

- λ st :

-

stagnation thermal conductivity of liquid steel (W·m−1·K−1)

- μ o :

-

magnetic permeability of vacuum (Wb·m−1·A−1)

- θ :

-

angular coordinate

- ρ :

-

mass density (kg·m−3)

- ρ R :

-

electrical resistivity of the steel billet (Ω·m)

- σ :

-

Stefen–Boltzmann constant (W·m−2·K−4)

- τ :

-

time coordinate (s)

References

Steel Times, 1989, vol. 217 (11), p. 631

B. Bowman: I & SM, 1993, vol. 20 (10), pp. 55–59

C. Bonnet and C. Roederer: Electric Furnace Conf. Proc., New Orleans, LA, Iron and Steel Society Inc., Pittsburgh, PA, 1990, vol. 48, pp. 429–35

S. Ueda, T. Nishimoto, H. Yamashita, Y. Kawazu, I. Kawakami, T. Maki, and N. Ao: Electric Furnace Conf. Proc., Toronto, Iron and Steel Society Inc., Pittsburgh, PA, 1991, vol. 49, pp. 173–76

J. Cui, and X. Liu: Iron and Steel (Chin.), 2006, vol. 41 (2), pp. 1–5

S.C. Beason: Electric Furnace Conf. Proc., Washington, DC, Iron and Steel Society Inc., Pittsburgh, PA, 1993, vol. 51, pp. 345–47

A.W. Kurley and E.G. Mueller: Electric Furnace Conf. Proc., Atlanta, GA, Iron and Steel Society Inc., Pittsburgh, PA, 1992, vol. 50, pp. 317–25

E.H. Nix and H.G. Muller: 4th Eur. Electric Steel Congr., Committee of Technology of Spanish Iron and Steel Industry, Madrid, Spain, 1992, pp. 131–37

P. Destannes, C. Lebrun, G. Maurer, P. Rivat, and D. Huin: 4th Eur. Electric Steel Congr., Committee of Technology of Spanish Iron and Steel Industry, Madrid, Spain, 1992, pp. 121–26

A.R. Janiak and G.J. Davene: U.S. Patent 4,821,284

Steel Times, 1993, vol. 221 (11), p. 471

Y.B. Zhu, D.L. Song, Z.S. Zeng, X.Y. Meng, and K.W. Hu: DC Arc Furnace Steelmaking Technology (chin.), Metallurgical Industry Press, Beijing, China, 1997, pp. 217–20

M. Pavlicevic, A. Kolesnichenko, A.D. Negra, and A. Poloni: U.S. Patent 5,889,809

M. Hamy and J. Michel: MPT, 1989, vol. 12 (5), pp. 54–60

N. Takashiba, K. Takahashi, Y. Oh-iwa, H. Numata, S. Otsubo, and P. Goujet: Electric Furnace Conf. Proc., Washington, DC, Iron and Steel Society Inc., Pittsburgh, PA, 1993, vol. 51, pp. 209–14

A.H. Castillejos, F.A. Acosta, M.A. Pedroza, M.A. Melendez, M.A. Herrera, and R.G. Gonzalez: Electric Furnace Conf. Proc., New Orleans, LA, Iron and Steel Society Inc., Pittsburgh, PA, 1998, vol. 56, pp. 525–34

K. Morgan, R.W. Lewis, and O.C. Zienkiewicz: Int. J. Num. Meth. Eng., 1978, vol. 12, pp. 1191–95

M.N. Ozisik: Basic Heat Transfer, McGraw-Hill Book Co., New York, NY, 1977, pp. 21–26

A.J. Chapman: Heat Transfer, 3rd ed., Macmillan Publishing Co., Inc., New York, NY, 1974, pp. 13–15

A.J. Chapman: Heat Transfer, 3rd ed., Macmillan Publishing Co., Inc., New York, NY, 1974, pp. 422–23

C. Gau, and R. Viskanta: Int. J. Heat Mass Transfer, 1984, vol. 27, pp. 113–23

FLUENT Manual 6.0 [M], FLUENT Inc., Lebanon, NH, 2002

W.D. Bennon, and F.P. Incropera: Int. J. Heat Mass Transfer, 1987, vol. 30, pp. 2162–70

W.D. Bennon, and F.P. Incropera: Int. J. Heat Mass Transfer, 1987, vol. 30, pp. 2171–87

F.R. Menter: 24th AIAA Fluid Dynamics Conf. Proc. (AIAA 93-2906), Orlando, FL, AIAA, Washington, DC, 1993, pp. 1–21

V.R. Voller, M. Cross, and N.C. Markatos: Int. J. Num. Methods Eng., 1987, vol. 24, pp. 271–84

X. Liu, Y.M. Zhou, H.L. Shi, and Y.L. Yan: Chinese Patent 03,230,028.X

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted July 23, 2007.

Rights and permissions

About this article

Cite this article

Liu, X., Zhou, J., Shi, H. et al. Melting Mechanism of Water-Cooled Billet-Type Bottom Electrode of Direct Current Arc Furnace: A Numerical Approach. Metall Mater Trans B 39, 713–724 (2008). https://doi.org/10.1007/s11663-008-9189-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-008-9189-8