Abstract

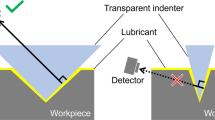

Cylindrical specimens of Electrical Conductivity grade aluminum were upset between flat platens to study the metal flow at room temperature. Platen-specimen-interface lubrication and specimen aspect ratio (height/diameter) were studied as process parameters. A vision system using PC-based video recording with a CCD (charge coupled device) camera was used to study the predrawn grid deformation at the midplane of the specimen and corresponding flow behavior. The forming process has been modeled and analyzed using the finite element software ANSYS. Lubrication minimized barreling of the lateral-free surface. Barreling decreased with increased aspect ratio. Microhardness studies reveal nonuniform deformation within the specimen. This effect was pronounced with high friction and low aspect ratio.

Similar content being viewed by others

Notes

LECO is a trademark of LECO Corporation, St. Joseph, MI.

References

H. Kudo, K. Aoi: J. Jpn. Soc. Techn. Plast., 1967, vol. 8, pp. 17–27

P.F. Thomason: Int. J. Mech. Sci., 1968, vol. 11, pp. 187–98

S. Kobayashi: J. Eng. Industry, Trans. ASME, 1970, Ser. B, vol. 92 (2), pp. 391–99

H.A. Kuhn, P.W. Lee: Metall. Trans., 1971, vol. 2, pp. 3197–3202

M. Kunogi: Reports of the Scientific Research Institute, Tokyo, 1954, vol. 30, p. 63

A.T. Male and M.G. Cockcroft: J. Inst. Met., 1964–65, vol. 93, p. 38

M. Jolgaf, A.M.S. Hamouda, S. Sulaiman, M.M. Haddar: J. Mater. Processing Technol., 2003, vol. 138, pp. 436–42

R. Shivpuri: Trans. Ind. Inst. Met., 2004, vol. 57 (4), pp. 345–66

T. Altan and D. Hannan: Forging: Prediction and Elimination of Defects in Cold Forging Using Process Simulation–The Engineering Research Center for Met Shape Manufacturing, 2002, http.www.ercnsm.org

V. Vazquez, T. Altan: J. Mater. Processing Technol., 2000, vol. 98, pp. 212–23

S. Kobayashi, S.I. Oh, T. Altan: Metal Forming and the Finite Element Method, Oxford University Press, New York, NY, 1989

L.H. Butler: Metallurgia, 1957, vol. 55, pp. 63–66

L.H. Butler: Metallurgia, 1960, vol. 61, pp. 167–74

L.H. Butler: J. Inst. Met., 1959–60, vol. 88, pp. 337–43

E. Tanaka, S. Semoto, and S. Wantanabe: Tohoku University Science Report Research Institute, Tohoku University, Sendai, Japan, 1965, Ser. A, vol. 17, pp. 208–18

E.P. Unksov: An Engineering Theory of Plasticity, Butterworth, London, 1961

K.M. Kulkarni, S. Kalpakjian: J. Eng. Ind., 1969, vol. 91, pp. 743–54

T. Ungair, J. Gubicza, G. Ribairik, A. Borbeily: J. Appl. Crystallogr., 2001, vol. 34, p. 298

Y. Iwahashi, Z. Horita, M. Nemota, T.G. Langdon: Metall. Mater. Trans. A, 1998, vol. 29A, p. 2503

S. Komlira, Z. Horita, M. Nemoto, T.G. Longdon: J. Mater. Res., 1999, vol. 14, p. 4044

E. Parteder, R. Bunten: J. Mater. Processing Technol., 1998, vol. 74, pp. 227–33

J.H. Hollomon: Trans. AIME, 1945, vol. 162, p. 268

W. Tong: J. Mech. Phys. Solids, 1998, vol. 46 (10), pp. 2087–2102

J.A. Bailey: Int. J. Mech. Sci., 1969, vol. 11, pp. 491–507

W.T. Wu, J.T. Jinn, and C.E. Fischer: Scientific Forming Technologies Corporation, ch. 15, http://www.asminternational.org/Template.cfm?Section=BrowsebyFormat&template=Ecommerce/FileDisplay.cfm&file=06701G_ch.pdf

http://www.matweb.com

C.H. Lee, S. Kobayashi: J. Eng. Ind. (Trans. ASME), 1973, vol. 95, p. 865

O.C. Zeinkiewiez: Numerical Analysis of Forming Processes, Wiley, New York, NY, 1984, pp. 1–44

Ansys 8.0 Reference Manual, ANSYS, Inc. Southpointe 275 Technology Drive Canonsburg, PA 15317

Acknowledgments

The authors thank the Department of Metallurgical Engineering and Department of Mechanical Engineering, Andhra University College of Engineering, Visakhapatnam, for providing necessary support in conducting the experiments.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted November 2, 2006.

Rights and permissions

About this article

Cite this article

Kamaluddin, S., Rao, J.B., Sarcar, M. et al. Studies on Flow Behavior of Aluminum Using Vision System during Cold Upsetting. Metall Mater Trans B 38, 681–688 (2007). https://doi.org/10.1007/s11663-007-9070-1

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-007-9070-1