Abstract

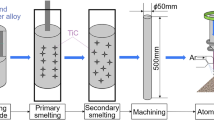

A novel processing technology was developed to investigate in situ synthesis of TiC-Al (Ti) nanocomposite powders by thermal plasma technology. Thermodynamic analysis was performed to predict possible starting materials and synthesizing conditions of TiC-Al (Ti) nanocomposite powders. A mathematical model was developed to describe temperature profile and velocity distribution in the reactor. The model is applied to optimize feeding rate, input power, and other processing parameters of TiC-Al (Ti) nanocomposite powders by thermal plasma technology, and to predict which materials can be used as starting materials. This paper emphasizes the investigation of the effect of feeding rate, input power, mole ratio, and other process parameters on synthesis of TiC-Al (Ti) nanocomposite powders by thermal plasma technology. The experimental results showed that TiC-Al (Ti) nanocomposite powders can be synthesized in situ by thermal plasma technology, and the average size of TiC-Al (Ti) nanocomposite powders was less than 100 nm.

Similar content being viewed by others

References

S.C. Tjong and Z.Y. Ma: Rev. J. Mater. Sci. Eng., 2000, vol. 29, pp. 49–113.

V.M. Kevorkijan: J. Metal., 1999, vol. 51 (11), pp. 54–58.

B. Maruyama and W.H. Hunt, Jr.: J. Metal., 1999, vol. 51 (11), pp. 59–61.

W.H. Hunt, Jr. and B. Maruyama: J. Metal., 1999, vol. 51 (11), pp. 62–64.

B. Maruyama: J. Metal., 1999, vol. 51 (11), pp. 47–55.

Q. Zheng and R.B. Reddy: J. Mater. Sci., 2004, vol. 39 (1), pp. 141–49.

V.M. Kevorkijan: Adv. Mater. Progress, 1999, vol. 5, pp. 27–29.

P.R. Taylor and S.A. Pirzada: Metall. Trans. B, 1992, vol. 23B, pp. 443–51.

Q. Zheng and R.B. Reddy: Metall. Mater. Trans. B, 2003, vol. 34B, pp. 793–804.

S. Niyomwas, B. Wu, and R.G. Reddy: Ultrafine Grained Materials, edited by B.S. Mishra, S.L. Semiatin, C. Suryanarayana, N.N. Thandhani, and T.C. Lowe. TMS, Warrendale, PA, 2000, pp. 89–98.

S. Mitrofranov, A. Mazza, and E. Pfender: Mater. Sci. Eng., 1981, vol. 48, pp. 21–26.

P.R. Taylor and M. Manrique: J. Metal., 1996, vol. 6, pp. 43–45.

F. Allaire, L. Parent, and S. Dallaire: J. Mater. Sci., 1991, vol. 26, pp. 6736–40.

A. Roine: “HSC Chemistry 4.1,” Chemical Reaction and Equilibrium Software with Extensive Thermodynamic Database, Outokumpu Research Oy, Finland, 1999.

N.A. Gokcen and R.G. Reddy: Thermodynamics, Plenum, New York, NY, 1996, p. 203.

R.G. Reddy: Metall. Mater. Trans. B, 2003, vol. 34B, pp. 137–52.

L. Tong and R.G. Reddy: in Developments in Theoretical and Applied Mechanics, edited by H. Mahfuz and M.V. Hosur, Tuskegee, AL, 2004, vol. XXII, pp. 656–88.

S. Niyomwas, B. Wu, and R.G. Reddy: in Materials Processing in the computer Age III, edited by V.R. Voller et al., TMS, Warrendale, PA, 2000, pp. 199–210.

L. Tong and R.G. Reddy: Scripta Mater., 2005, vol. 52, pp. 1253–58.

J.P. Hirth and G.M. Pound: Condensation and Evaporation: Nucleation and Growth Kinetics, MacMillan, New York, NY, 2000, pp. 15–19.

S.K. Friedlander: Smoke, Dust, and Haze: Fundamentals of Aerosol Dynamics, Oxford University Press, New York, 2000.

B.D. Cullity: Elements of X-ray Diffraction, 2nd ed. Addison-Wesley Publishing Company, Inc., U.S.A., 1978, p. 115.

C. Suryanarayana and M.G. Norton: X-ray Diffraction: A Practical Approach, Plenum, New York, NY, 1998, p. 97.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Tong, L., Reddy, R.G. In situ synthesis of TiC-Al (Ti) nanocomposite powders by thermal plasma technology. Metall Mater Trans B 37, 531–539 (2006). https://doi.org/10.1007/s11663-006-0036-5

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11663-006-0036-5