Abstract

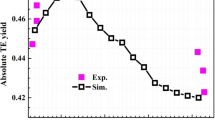

Scanning electron microscopy (SEM) has been used as a surface measurement instrument and a tool for lithography in semiconductor processes due to its high-density localized beam. For those purposes, however, the maximum current of SEM is less than 100 pA, which is not enough for material processing. In this article, SEM was modified to increase the amount of current reaching a specimen from the gun part where the current is generated. The maximum current of SEM after modifications was measured at up to 10 µA, which is 105 times greater than before modifications. The current reaching the specimen is called the probe current, which can be defined as a heat source for material processing. The electron beam of the probe current scans rapidly over an area defined by SEM magnification. By considering the electron beam scanning period and the reaction between high-speed electrons and solid material, the heat source model of the rapidly scanning SEM electron beam was suggested. The simulation results with suggested heat source by ABAQUS were compared with the experiment results.

Similar content being viewed by others

References

U. Dilthey, A. Brandenburg, M. Moller, and G. Smolka: Schweissen Schneiden, 2000, July, pp. E.143–E.146.

S.V. Dubonos, H.F. Raith, A.A. Svintsov, and S.I. Zaitsev: Microprocesses Nanotechnology Conf., Yokohama, Japan, 1999, pp. 110–11.

E. Lavallee, J. Beauvais, and D. Drouin: Electron. Lett., 1999, vol. 36 (18), pp. 1589–90.

R. Nami, S. Magoshi, S. Kousai, M. Hmada, T. Takayanagi, K. Sugihara, K. Okumura, and T. Kuroda: Electron Devices Meeting, 2000, IEDM Technical Digest International, San Francisco, CA, 2000, pp. 833–36.

H. Schwarz: J. Appl. Phys., 1964, vol. 35 (7), pp. 2020–29.

J.I. Goldstein, D.E. Newbury, P. Echlin, D.C. Joy, A.D. Romig, Jr., C.E. Lyman, C. Fiori, and E. Lifshin: Scanning Electron Microscopy and X-Ray Microanalysis, 2nd ed., Plenum Press, New York, NY, 1992.

J.I. Goldstein and H. Yakowitz: Practical Scanning Electron Microscopy, Plenum Press, New York, NY, 1975.

E. Koleva, G. Mladenov, and K. Vutova: Vacuum, 1999, vol. 53, pp. 67–70.

G. Mladennov, K. Vutova, and S. Wojcicki: Vacuum, 1998, vol. 51 (2), pp. 231–33.

F.P. Incropera and D.P. Dewitt: Fundamentals of Heat and Mass Transfer, 3rd ed., Incropera, Willy, John Wiley & Sons, Inc., 1981.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Hwang, IH., Na, SJ. A study on heat source modeling of scanning electron microscopy modified for material processing. Metall Mater Trans B 36, 133–139 (2005). https://doi.org/10.1007/s11663-005-0013-4

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11663-005-0013-4