Abstract

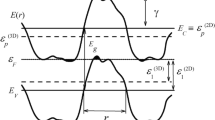

This article reviews recent developments in thin film growth and formation of three-dimensional epitaxial nanostructures. First, we present a unified standard model for thin film epitaxy, where single-crystal films with small and large lattice misfits are grown by a new paradigm of domain matching epitaxy (DME). We define epitaxy as having a fixed orientation rather than the same orientation with respect to the substrate. The DME involves matching of integral multiples of lattice planes (diffracting as well as nondiffracting) between the film and the substrate, and this matching could be different in different directions. The idea of matching planes is derived from the basic fact that during thin film growth, lattice relaxation involves generation of dislocations whose Burgers vectors correspond to missing or extra planes, rather than lattice constants. In the DME framework, the conventional lattice matching epitaxy (LME) becomes a special case where matching of lattice constants results from matching of lattice planes with a relatively small misfit of less than 7 to 8 pct. In large lattice mismatch systems, we show that epitaxial growth of thin films is possible by matching of domains where integral multiples of lattice planes match across the interface. We illustrate this concept with atomic-level details in the TiN/Si(100) with 3/4 matching, the AlN/Si(100) with 4/5 matching, and the ZnO/α-Al2O3(0001) with 6/7 matching of lattice planes across the film/substrate interface. By varying the domain size, which is equal to the integral multiple of lattice planes, in a periodic fashion, it is possible to accommodate additional misfit beyond the perfect domain matching. Thus, we can potentially design epitaxial growth of films with any lattice misfit on a given substrate with atomically clean surfaces as long as there is wetting or finite interatomic interaction across the interface and cores of dislocations do not overlap. In-situ X-ray diffraction studies on initial stages of growth of ZnO films on sapphire correctly identify a compressive stress and a rapid relaxation within one to two monolayers, consistent with the DME framework and the fact that the critical thickness is less than a monolayer. The DME examples ranging from the Ge-Si/Si(100) system with 49/50 matching (2 pct strain) to metal/Si systems with 1/2 matching (50 pct strain) are tabulated, strategies for growing strain-free films by engineering the misfit to be confined near the interface are presented, and the potential for epitaxial growth of films with any lattice misfit on a given substrate with atomically clean surfaces is discussed. In the second part, we discuss the formation of epitaxial nanodots/nanocrystals in crystalline matrices such as MgO and TiN. The formation Ni nanocrystals inside MgO involves lattice misfit ranging from 3.0 to 31.3 pct, and the formation of Ni nanocrystals in TiN has a misfit of about 17 pct. To form epitaxial nanodots, we use DME framework to grow nanodots inside crystalline matrices. Growth characteristics and crystallography of nanodots are controlled to enhance the overall properties of nanostructured materials. We illustrate this for nanostructured magnetic materials where coercivity and blocking temperature can be considerably enhanced by controlling the orientation for magnetic memory and storage applications, among others. In the last part, the DME principles are applied to grow self-assembled epitaxial nanodots using pulsed laser deposition. By controlling the clustering kinetics, it is possible to obtain a uniform distribution of epitaxial nanodots and overcome thermodynamically driven Ostwald ripening. This process allows the formation of epitaxial nanostructures via three-dimensional self-assembly, the “holy grail” of nanostructured materials processing, leading to unique and novel properties.

Similar content being viewed by others

References

J. Narayan and B.C. Larson: J. Appl. Phys., 2003, vol. 93, p. 278–85.

H.J. Queisser and E.E. Haller: Science, 1998, vol. 281, p. 945–50.

S. Nakamura: Science, 1998, vol. 281, p. 956–61.

S. Mahajan: Acta Mater., 2000, vol. 48, p. 137–45.

J.W. Mathews and A.E. Blakeslee: J. Cryst. Growth, 1974, vol. 27, p. 118–25.

J.W. Mathews: in Epitaxial Growth, Part B, Materials Science Series 560, Academic Press, New York, NY, 1975.

J. Narayan and S. Sharan: Mater. Sci. Eng., 1991, vol. B10, p. 261–67.

F.K. LeGoues, M.C. Reuter, J. Tersoff, M. Hammer, and R.M. Tromb: Phys Rev. Lett., 1994, vol. 73, p. 300–03.

J. Narayan, P. Tiwari, X. Chen, R. Chowdhury, and T. Zheleva: Appl. Phys. Lett., 1992, vol. 61, p. 1290–92.

J. Narayan: U.S. Patent 5,406,123, April 11, 1995.

T. Zheleva, K. Jagannadham, and J. Narayan: Appl. Phys. Lett., 1994, vol. 75, p. 860–62.

R.D. Vispute, R. Chandhury, P. Tiwari, and J. Narayan: Appl. Phys. Lett., 1994, vol. 65, p. 2565–67.

R.D. Vispute, H. Wu, and J. Narayan: Appl. Phys. Lett., 1995, vol. 67, p. 1549–51.

R.D. Vispute, J. Narayan, and J.D. Budai: J. Appl. Phys., 1996, vol. 80, p. 6720–24.

J. Narayan, K. Dovidenko, A. Sharma, and S. Oktyabrsky: J. Appl. Phys., 1998, vol. 84, p. 2597–601.

A.K. Sharma, J. Narayan, C. Jin, A. Kvit, S. Chattopadhyay, and C.B. Lee: Appl. Phys. Lett., 2000, vol. 76, p. 1458–60.

W. Bollmann: Crystal Defects and Crystalline Interfaces, Springer, Berlin, 1970; S. Okytyabrsky, K. Kalyanraman, K. Jagannadham, and J. Narayan, J. Mater. Res., 1999, vol. 14, p. 2764–72.

J.-M. Penisson: in Interface Science and Engineering, R. Raj and S.L. Sass, eds., J. de Phys., 1988, vol. C5, p. 87.

J. Narayan: J. Appl. Phys., 1985, vol. 37, p. 2703–09.

J.P. Hirth and J. Lothe: Theory of Dislocations, P., John Wiley, New York, NY, 1998.

S. Strite and H. Morkoc: J. Vac. Sci. Technol., 1992, vol. B10, p. 1237–66.

S.C. Jain, M. Willander, J. Narayan, and R. Van Overstraeten: J. Appl. Phys., 2000, vol. 87, p. 965–1006.

T.A. Rawdanowicz and J. Narayan: Appl. Phys. Lett., 2004, vol. 85, p. 133–35.

J. Narayan, A.K. Sharma, A. Kvit, C. Jin, J.F. Muth, and O.W. Holland: Solid State Comm., 2002, vol. 121, p. 9–13.

M. Ichimura and J. Narayan: Phil. Mag., 1995, vol. A 72, p. 297–304.

H. Porter and J. Narayan: Mater. Sci. Eng. B, in press.

A.E. Hughes and S.C. Jain: Adv. Phys., 1979, vol. 28, p. 279–304.

J. Narayan, Y. Chen, and R.M. Moon: Phys. Rev. Lett., 1981, vol. 46, p. 149–152: J. Narayan and Y. Chen: U.S. Patent 4,376,755, 1983.

J. Narayan, Y. Chen, R.M. Moon, and R.W. Carpenter: Phil. Mag., 1984, vol. 49, 287–300.

J. Narayan and Y. Chen: Phil. Mag., 1984, vol. 49, p. 475–92.

H. Zhou, D. Kumar, A. Kvit, and J. Narayan: J. Appl. Phys., 2003, vol. 94, p. 4841–46.

A.P. Alivisatos: Sci., 1996, vol. 271, p. 933–37.

D.D. Awschalom, D.P. DiVincenzo, and J.F. Smyth: Science, 1992, vol. 258, p. 414–19.

V.F. Puntes, K.M. Krishnan, A.P. Alivisatos: Science, 2001, vol. 291, p. 2115–17.

J.S. Moodera, E.F. Gallagher, K. Robinson, and J. Nowak: Appl. Phys. Lett., 1997, vol. 70, p. 3050–52.

J. Müller, C. Sönnichsen, H. von Poschinger, G. von Plessen, T.A. Klar, and J. Feldmann: Appl. Phys. Lett., 2001, vol. 81, p. 171–73.

C.T. Black, C.B. Murray, R.L. Sandstrom, and Shouheng Sun: Science, 2000, vol. 290, p. 1131–34.

D.N. Lambeth, E.M.T. Velu, G.H. Bellesis, L.L. Lee, and D.E. Laughlin: J. Appl. Phys., 1996, vol. 79, p. 4496–501.

F. Mazaleyrat and L.K. Varga: J. Magn. Magn. Mater., 2000, vol. 215, p. 253–59.

H. Koo, C. Krafft, and R.D. Gomez: Appl. Phys. Lett., 2002, vol. 81, p. 862–64.

B. Stahl, N.S. Gajbhiye, G. Wilde, D. Kramer, J. Ellrich, M. Ghafari, H. Hahn, H. Gleiter, J. Weissmuller, R. Wurschum, and P. Schlossmacher: Adv. Mater., 2002, vol. 14, p. 24–27.

Mark J. MacLachlan, M. Ginzburg, N. Coombs, T.W. Coyle, N.P. Raju, J.E. Greedan, G.A. Ozin, and I. Manners: Science, 2000, vol. 287, p. 1460–64.

J. Narayan and A. Tiwari: J. Nanosci. Nanotechnol., 2004, vol. 4, p. 726–32; U.S. Patent 2004/0119064, June 24, 2004.

V.A. Shchukin and D. Bimberg: Rev. Mod. Phys., 1999, vol. 71, p. 1125–71.

J. Tersoff, C. Teichert, and M.G. Lagally: Phys. Rev. Lett., 1996, vol. 76, p. 1675–78.

Feng Liu, Sarah E. Davenport, Heather M. Evans, and M.G. Lagally: Phys. Rev. Lett., 1999, vol. 82, p. 2528–31.

H.L. Porter, V. Bhosle, and J. Narayan: J. Appl. Phys., in press.

Additional information

Jagdish (Jay) Narayan holds The John C.C. Fan Family Distinguished Chair Professorship and is Director of the NSF Center for Advanced Materials and Smart Structures at North Carolina State University. The Edward DeMille Campbell memorial lecture entitled, “New Frontiers in Thin Film Growth and Nanomaterials,” was delivered at the Annual ASM International Meeting (October 17–20, 2004) in Columbus, Ohio.

Professor Narayan received his M.S. (1970) and Ph.D. (1971) degrees in a record time of two years from the University of California, Berkeley, after his Bachelor’s of Technology with Distinction and Highest Honors from IIT, Kanpur in 1969. Professor Narayan has had a profound impact on our understanding of defects and interfaces in thin film heterostructures, laser-solid interactions and processing of novel materials, controlled thin film growth and self-assembled nanostructures, and nanoscale characterization and modeling of new materials and properties. He invented novel supersaturated semiconductor alloys formed by solid phase epitaxy, and by liquid-phase crystallization where melt-quenching rates are billions of degrees per second. This research, featured twice in Science Magazine, has resulted in numerous U.S. patents and three IR-100 Awards. More recently, Narayan has pioneered and patented a new concept of domain epitaxy, where an integral number of lattice planes of the film match that of the substrate in large lattice mismatched systems. The domain epitaxy is key to the formation of thin film heterostructures, such as TiN films on silicon with 4/3 matching, and III-nitrides and ZnO films on sapphire with 6/7 matching. Narayan invented new cubic ZnMgO alloys, which can be grown epitaxially on silicon (100) substrates for integrating optoelectronic and spintronic devices. Narayan discovered and patented a new method of self-assembly for processing nanostructured magnetic, photonic, electronic, and structural materials. His discoveries with Dr. John Fan, Kopin Corporation, related to domain epitaxy and quantum confinement by thickness variation (creating nanopockets) are being used by Kopin Corp. to manufacture high-efficiency light emitting diodes for solid-state lighting. He has published over 800 scientific articles, edited 9 books, and received 22 patents pertaining to novel materials and processing methods, domain epitaxy, and a new class of next-generation semiconductor alloys. He is a Fellow member of APS, AAAS, ASM International, TMS, and MRS-I. He has won numerous other honors, including three IR-100 Awards and a 1999 ASM Gold Medal. He also received Distinguished Alumnus Honors from IIT/K in 1997.

Rights and permissions

About this article

Cite this article

Narayan, J. New frontiers in thin film growth and nanomaterials. Metall Mater Trans B 36, 5–22 (2005). https://doi.org/10.1007/s11663-005-0001-8

Issue Date:

DOI: https://doi.org/10.1007/s11663-005-0001-8