Abstract

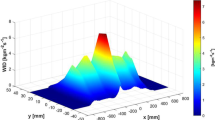

The mathematical model to compute the thermal evolution and solidification of thin slabs, previously presented in Part I of this article, was used in combination with a three-dimensional (3-D) finite-element thermomechanical model to analyze how actual operation conditions can lead to excessive deflection and jamming of the slab shell at the pinch rolls. The models suggest that these phenomena arise from a sudden loss of control of the metallurgical length stemming from the coupling of inappropriate steel superheats and casting velocities to deficient heat-extraction conditions at the mold or secondary cooling system. The bulging deformation was calculated with an elastic and creep model that takes into account the temperature distribution across the shell thickness and the different times that shell elements have to creep exposure, i.e., according to the time that rows of elements require to reach their current position in the casting direction at a given casting speed. The last point was simulated by varying the duration of application of the ferrostatic load to the inside surface of each row of elements. The conditions forecast by the models as being responsible for excessive bulging agree very well with those present during the occurrence of these events in the plant. Since bulging after the last containment roll is a major limitation to productivity, this article also presents a parametric evaluation of the casting-speed limits that two compact-strip process (CSP) casters with different supported lengths may have as a function of steel superheat, mold heat-extraction level, water flow rate of the spray and air-mist nozzles, and slab thickness.

Similar content being viewed by others

Abbreviations

- A :

-

creep coefficient

- E :

-

young’s modulus (Pa)

- f j :

-

body force vector (kg m s−2)

- g :

-

gravity acceleration, (m s−2)

- i :

-

index denoting rows of finite elements (1, ..., N=20)

- k, k l , k s :

-

local thermal conductivity of steel (=f s k s +(1−f s ) k l ); of liquid steel; of solid steel (W/mK)

- k sol :

-

solidification constant of casting machine (=y s (u cs /L met)1/2) (mm/min1/2)

- l c, lc1, lc2 :

-

supported length of caster; of caster 1; of caster 2 (m)

- l M :

-

metallurgical length (m)

- m, n :

-

power-law creep exponents

- N :

-

number of rows of finite elements located over the z s length of the shell

- p s :

-

ferrostatic pressure (Pa)

- q bf :

-

heat flux at the mold broad face (MW/m2)

- S ij :

-

stress deviator tensor (Pa)

- T liq, T sol :

-

liquidus and solidus steel temperatures (°C)

- ΔT h :

-

steel superheat in the mold (°C)

- u cs :

-

casting speed (m/min)

- u i :

-

displacement vector (m)

- W :

-

water flow rate per nozzle (L/s)

- W s :

-

slab half-width (m)

- x i :

-

x,y,z Cartesian coordinate directions

- z i :

-

position of the ith row of elements relative to the meniscus, m

- x s , y s , z s :

-

half-width, half-thickness, and length of slab section sketched in Fig. 1 (m)

- t, t s :

-

time, time in which the slab travels one element length (s); slab thickness (mm)

- δ ij :

-

Kronecker’s delta

- ɛ Ce , ɛ Cij :

-

effective creep strain, creep strain tensor

- ρ, ρ l , ρ s :

-

local density of steel (=f s ρ s +(1−f s ) ρ l ); of liquid steel; of solid steel (kg/m3)

- σ e , σ ij :

-

effective stress; stress tensor (Pa)

References

Modeling and Analysis of Manufacturing Systems, R.G. Askin and C.R. Standridge, eds., Wiley, New York, NY, 1993, p. 69.

J.E. Camporredondo S., A.H. Castillejos E., F.A. Acosta G., E.P. Gutiérrez M., and M.A. Herrera G.: Metall. Mater. Trans. B, 2004, vol. 35B, pp. 541–60.

H.L. Gilles: Steelmaking Conf. Proc., ISS-AIME, Pittsburgh, PA, 1993, pp. 315–29.

S.K. Ray, P.C. Das, and S.K. Subir: Scand. J. Metall., 1994, vol. 23, pp. 126–29.

T.A. Kajitani, J.-M. Drezet, and M. Rappaz: Metall. Mater. Trans. A, 2001, vol. 32, pp. 1479–91.

B.A. Barber, B.M. Leckenby, and B.A. Lewis: Ironmaking and Steelmaking, 1991, vol. 18, pp. 431–36.

Z. Han, K. Cai, and B. Liu: Iron Steel Inst. Jpn. Int., 2001, vol. 41, pp. 1473–80.

S. Du, B. Ye, and J. Yang: Iron and Steel (Peking), 1995, vol. 30, pp. 23–27.

B. Thomas, A. Moitra, and H. Zhu: Proc. Conf. on Modeling of Casting, Welding and Advanced Solidification Processes, London, Sept. 10–15, 1995, TMS, Warrendale, PA, 1995, pp. 241–48.

J.D. Lee and C.H. Yim: Iron Steel Inst. Jpn. Int., 2000, vol. 40, pp. 765–70.

K.M. Markarian, A.J. Rumler, W.H. Emling, and P.A. Ream: I&SM, 1991, vol. 18, pp. 43–51.

Creep Analysis: H. Kraus, ed., Wiley, New York, NY, 1980.

K.-H. Tacke: in Metallurgie des Stranggießens, K. Schwerdtfeger, ed., Stahleisen, Dusseldorf, 1992, pp. 358–401.

K. Miyazawa and K. Schwerdtfeger: Ironmaking and Steelmaking, 1979, vol. 6, pp. 68–74.

J. Ren and Z. Wang: Ironmaking and Steelmaking, 1998, vol. 25, pp. 394–97.

A. Grill and K. Schwerdtfeger: Iron Steelmaking, 1979, vol. 3, p. 131.

B.A. Lewis, B. Barber, and N.J. Hill: Appl. Math. Modelling, 1983, vol. 7, pp. 274–77.

J.S. Ha, J.R. Cho, B.Y. Lee, and M.Y. Ha: J. Mater. Processing Technol., 2001, vol. 113, pp. 257–61.

C. Li and B.G. Thomas: The Brimacombe Memorial Symp., Vancouver, Oct. 1–4, 2000, G.A. Irons and A.W. Cramb, pp. 595–611.

M.M. Wolf: I&SM, 1996, vol. 23, pp. 47–51.

R. Santos P.: Hylsa S.A. de C.V., San Nicolás de los Garza, N.L. México, private communication, 2003.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Camporredondo S., J.E., Acosta G., F.A., Castillejos E., A.H. et al. Analysis of thin-slab casting by the compact-strip process: Part II. Effect of operating and design parameters on solidification and bulging. Metall Mater Trans B 35, 561–573 (2004). https://doi.org/10.1007/s11663-004-0055-z

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11663-004-0055-z