Abstract

This article reports on an extensive experimental and modeling study undertaken to elucidate the thermal evolution of thin slabs during their passage through the mold and secondary cooling system of a compact-strip process (CSP) caster. In industrial trials covering a wide range of casting conditions, temperature measurements were carried out at (1) the copper plates of an operating mold and (2) the stainless steel frame of an operating grid. Separately, water-flux and heat-flux distributions generated by the several water and air-mist sprays produced by the different nozzles used in the process were determined in the laboratory. The analysis of these pieces of information, together with a detailed consideration of the geometry of the mold and the arrangement of the rolls and spray nozzles, were used to establish appropriate boundary conditions for a two-dimensional, curvilinear-coordinate, unsteady-state heat-conduction model for predicting the solidification rate of thin slabs. The predicted slab surface temperatures show very good agreement with corresponding measured values taken in plant tests at several locations along and across the secondary cooling system. The validation trials involved a wide range of low- and medium-carbon steel grades, casting speeds, slab widths, and secondary cooling strategies. The second part of this article combines the solidification model with a creep model of the shell to yield useful information about design parameters and casting conditions associated with undesirable bulging behavior of the slab after the last support roll, which causes stoppage of the process by slab clogging at the pinch rolls.

Similar content being viewed by others

Abbreviations

- a, b, c, d :

-

coefficients in correlations for slab heat flux by direct water impingement

- a, b, a 1, b 1 :

-

dimensions of the rectangular contours corresponding to maximum and minimum impact water flux (m)

- A, A s :

-

cross-sectional area of computational slice, outside the mold funnel A=A s (m2)

- Bi:

-

Biot number (=h wfyc/km)

- C p :

-

heat capacity of steel (=C pl for T>T liq;=C p ′=C pl +ΔH/(T liq−T sol) for T sol≤T≤T liq;=C ps for T<T sol) (J/kgK)

- f s :

-

local fraction of solid steel (f s =0 for T>T liq; f s =(T liq−T)/(T liq−T sol) for T sol≤T≤T liq; f s =1 for T<T sol)

- h eff, h mn, h v , h wf :

-

heat-transfer coefficients; by convection and radiation at grid windows; by natural convection at cold face of mold plate; by water vapor films; by forced convection to water in mold slots (W/m2 °C)

- ΔH :

-

latent heat of melting of steel (kJ/kg)

- k, k l , k s :

-

local thermal conductivity of steel (=f s k s +(1−f s )k l ); of liquid and solid steel (W/mK)

- k m , k r , k v :

-

thermal conductivity of mold plate; steel roller; water vapor films (W/mK)

- k sol :

-

solidification constant of casting machine (=y s (u cs /l M )1/2) (mm/min1/2)

- l, l M :

-

length of secondary cooling zones; metallurgical length (m)

- q bf , q nf :

-

heat flux at the mold broad face; at mold narrow face (MW/m2)

- q ra , q g , q i , q r1, q sl, q s2 :

-

heat flux at the slab surface in rebound drops and water accumulation regions; in grid ribs regions; in direct water impingement regions at the i secondary cooling zone; in rolls regions; in broad and narrow planes of symmetry (MW/m2)

- Q a :

-

air flow rate per nozzle (Nm3/s)

- pct RA:

-

percent reduction of area at fracture

- t :

-

time elapsed from the instant the steel slice is at the meniscus (s)

- T, T c , T m :

-

local mold or steel temperature; computed and measured temperatures at thermocouple locations (°C)

- T s , T T liq :

-

calculated temperature of hot face of mold plate or measured or calcalculated temperature of slab surface; solidus and liquidus steel temperatures (°C)

- T t , T w , T 0, T ∞ :

-

temperature of steel in tundish; of water in mold slots; initial steel temperature; of water vapor films (°C)

- ΔT :

-

temperature difference (T s −T 0), used in correlations for q i (°C)

- ΔT r :

-

maximum difference in roll surface temperature by cyclic contact with slab (°C)

- u cs :

-

slab casting speed (m/min)

- w, w max :

-

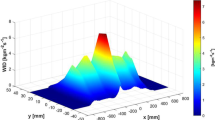

local and maximum water fluxes impinging on slab (L/m2s)

- W :

-

water flow rate per nozzle (L/s)

- W m , W s :

-

mold width; slab half-width (m)

- x, y, z :

-

Cartesian coordinates

- x g , z g :

-

horizontal and vertical positions in the grid relative to centerline and top (m)

- y s , y c :

-

half-thickness of the slab after mold funnel, y position of cooling slots (m)

- z m :

-

meniscus level (mm)

- α r :

-

thermal diffusivity of the rolls (m2/s)

- δ(x) :

-

local semithickness of slab at a given z position (m)

- δ y :

-

thickness of the vapor films in rebound drops or water accumulation zones (m)

- ɛ, ɛ f :

-

emissivity of strand surface; true strain to fracture

- π :

-

constant (=3.1416)

- ρ, ρ l , ρ s :

-

local density of steel (=f s ρ s + (1−f s ) ρ l ); of liquid steel; of solid steel (kg/m3)

- σ :

-

Stefan-Boltzmann constant (=5.6703 × 10−8 W/m2K4)

- i, t:

-

iteration step, time step, or secondary cooling zone; thermocouple

- m, c, e, g, g12, g3, g4 r, ra, 3, 4, 5, 6:

-

mold; central zone; external zone; grid; grid window rows 1 through 4; ring; rebound drops or water accumulation regions; cooling zones

References

A.W.D. Hills: J. Iron Steel Inst., 1965, vol. 203, pp. 18–26.

E.A. Mizikar: Trans. TMS-AIME, 1967, vol. 239, pp. 1747–53.

J.K. Brimacombe, J.E. Lait, and F. Weinberg: Proc. Conf. on Mathematical Process Model in Iron- and Steelmaking, Amsterdam, Feb. 19–21, 1973, J.M. van Langen, et al., eds., The Metals Society, London, 1975, pp. 174–86.

C. Li and B.G. Thomas: The Brimacombe Memorial Symp., Vancouver, Oct. 1–4, 2000, G.A. Irons and A.W. Cramb, eds., Met. Soc.—CIM, Montreal, 2000, pp. 595–611.

J.S. Ha, J.R. Cho, B.Y. Lee, and M.Y. Ha: J. Mater. Proc. Technol., 2001, vol. 113, pp. 257–61.

J. Konishi, M. Militzer, J.K. Brimacombe, and I.V. Samarasekera: Metall. Mater. Trans. B, 2002, vol. 33, pp. 413–23.

J.K. Brimacombe and I.V. Samarasekera: Proc. Int. Symp. on Near-Net-Shape Casting in the Minimills, CIM, Vancouver, Aug. 19–23, 1995, Met. Soc.—CIM, Montreal, 1995, pp. 33–53.

K. Wünnenberg and K. Schwerdfeger: I&SM, 1995, Apr., pp. 25–31.

T.G. O’Connor and J.A. Dantzig: Metall. Mater. Trans. B, 1994, vol. 25, pp. 443–57.

J.K. Park, B.G. Thomas, I.V. Samarasekera, and U.S. Yoon: Metall. Mater. Trans. B, 2002, vol. 33B, pp. 425–36.

W. Hennig, F. Kueper, F.-P. Pleschiutschnigg, and E. Thomanek: 3rd Eur. Conf. on Continuous Casting, Madrid, Oct. 20–23, 1998, UNESID, Madrid, 1998, pp. 1–18.

F.-P. Pleschiutschnigg, G. Flemming, W. Hennig, F. Nordmeyer, and J. Schwellenbach: CSM Annual Meeting, Beijing, Oct. 19–21, 1999, Chinese Society for Metals, Beijing, 1999, pp. 1–14.

E. Macías A., A.H. Castillejos, F.A. Acosta G., M. Herrera, and F. Neumann: Ironmaking and Steelmaking, 2002, vol. 29, pp. 347–58.

F.-P. Pleschiutschnigg: CSM Annual Meeting, Beijing, Oct. 31–Nov. 2, 2001, vol. 1–39.

J.E. Camporredondo S.: 3er Reporte de Trabajo Doctoral, CINVESTAV-Unidad Saltillo, Coahuila, México, 2001.

E. Muñoz, B. Hernández, A.H. Castillejos, F.A. Acosta, and E. Gutiérrez: unpublished research, UNAM and CINVESTAV, 2003.

A.H. Castillejos E. and F.A. Acosta G.: CINVESTAV Report for HYLSA, S.A. de C.V., Dec. 2003.

Numerical Heat Transfer and Fluid Flow, Suhas V. Patankar, ed., McGraw-Hill, New York, New York, 1980, pp. 41–74.

Rate Phenomena in Process Metallurgy, J. Szekely and N.J. Themelis, eds., Wiley-Interscience, New York, New York, 1971, pp. 236.

C.A. Pinheiro, I.V. Samarasekera, and J.K. Brimacombe: I&SM, 1995, vol. 22, pp. 101–04.

M. Kawamoto, Y. Tsukaguchi, N. Nishida, T. Kanazawa, and S. Hiraki: Iron Steel Inst. Jpn. Int., 1997, pp. 134–39.

P.J. Wray: Modeling of Casting and Welding Processes, Rindge, NH, Aug. 3–8, 1980, H.D. Brody and D. Apelian, eds., The Metallurgical Society of AIME, Warrendale, PA, 1981, pp. 245–57.

K. Kawakami, T. Kitagawa, K. Murakami, Y. Miyashita, Y. Tsuchida, and K. Kawawa: Nippon Kokan Tech. Report, 1983, No. 93, pp. 149–63.

Heat Conduction, S. Kakaç and Y. Yener, eds., Hemisphere Publishing Corporation, New York, NY, 1985.

A. Diener and A. Drastik: Arch. Eisenhüttenwes., 1982, vol. 53, pp. 13–20.

R. Jeschar, H. Kraushaar, and H. Griebel: Steel Res., 1996, vol. 67, pp. 227–34.

M. Faghri, E.M. Sparrow, and A.T. Prata: Num. Heat Transfer, vol. 7, pp. 183–209.

CONDUCT—Computation of Conduction and Duct Flow Heat Transfer, Suhas V. Patankar, ed., University of Minnesota, 1988, pp. 143–53.

S.G. Hibbins and J.K. Brimacombe: ISS Trans., 1983, vol. 3, pp. 77–89.

H.L. Gilles: Steelmaking Conf. Proc., ISS-AIME, Pittsburgh, PA, 1993, pp. 315–29.

A.H. Castillejos E., A. Flores V., and F.A. Acosta G.: CINVESTAV Report for HYLSA, S.A. de C.V., San Nicolas, May 1996.

E. Muñoz M.A. Salinas R., A.H. Castillejos E., and M.A. Pedroza C.: Proc. J.J. Jonas Symp., MetSoc-CIM, Ottawa, Aug. 20–23, 2000, Met. Soc.—CIM, Montreal, 2000, pp. 645–56.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Camporredondo S., J.E., Castillejos E., A.H., Acosta G., F.A. et al. Analysis of thin-slab casting by the compact-strip process: Part I. Heat extraction and solidification. Metall Mater Trans B 35, 541–560 (2004). https://doi.org/10.1007/s11663-004-0054-0

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11663-004-0054-0