Abstract

The equilibrium partition ratios of Al, Ta, and Cr in Ni-rich alloys of the Ni-Al-Ta-Cr system were experimentally determined by isothermally holding at a temperature in the liquid-solid range of the alloys followed by quenching. The partition ratios apply to equilibria between metls and γ phase (fcc) in the range of 1615 to 1694 K. It was found that the equilibrium partition ratios in this system depend mainly on the concentration of Ta. The equilibrium partition ratio of Ta varies from approximately 0.6 at dilute Ta to 0.85 at 17 wt pct Ta. For the same range of Ta contents, less variability is seen in the partition ratios of Al and Cr, which range from about 0.92 to 0.96. In addition to the partition ratios, the liquidus temperatures of the liquid in equilibrium with γ in the Ni-Al-Ta-Cr system were estimated with a multidimensional regression analysis. The experimental results reported herein are complemented by a compilation of partition ratios of many solutes in binary and multicomponent Ni-base alloys.

Similar content being viewed by others

References

W.D. Bennon and F.P. Incropera: Metall. Trans. B, 1987, vol. 18B, pp. 611–16.

S.D. Felicelli, J.C. Heinrich, and D.R. Poirier: Metall. Trans. B., 1991, vol. 22B, pp. 847–59.

C. Beckermann: in Modeling of Casting, Welding and Advanced Solidification Processes VI, T.S. Piwonka, V. Voller, and L. Katgerman, eds., TMS, Warrendale, PA, 1993, pp. 181–92.

S.D. Felicelli, D.R. Poirier, and J.C. Heinrich: Metall. Mater. Trans. B, 1998, vol. 29B, pp. 847–55.

A. Kagawa, K. Iwata, A.A. Nofal, and T. Okamoto: Mater. Sci. Technol., 1985, vol. 1, pp. 678–83.

A. Morita and T. Tanaka: Trans. Iron Steel Inst. Jpn., 1983, vol. 23, pp. 824–33.

P.M.N. Ocansey and D.R. Poirier: Mater. Sci. Eng., 1996, vol. A211, pp. 10–14.

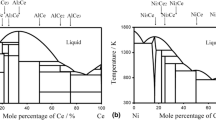

Binary Alloy Phase Diagrams, 2nd ed., T.B. Massalski, ed., ASM INTERNATIONAL, Materials Park, OH, 1990, vol. 1, p. 183; vol. 2, pp. 1215, 1301, 1736, and 2095; vol. 3, pp. 2637, 2747, 2848, 2867, 2875, 2881, and 2883.

Phase Diagrams of Binary Nickel Alloys, P. Nash, ed., ASM INTERNATIONAL, Materials Park, OH, 1991, pp. 4, 69, 75, 110, 164, 207, 220, 268, 320, 342, 362, and 368.

ASM Handbook, H. Baker, ed., ASM INTERNATIONAL, Materials Park, OH, 1992, vol. 3, pp. 49, 145, 155, 199, 241, 292, 304, 315, 319, and 320.

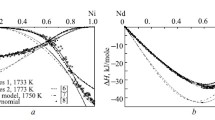

T. Tanaka, N. Imai, A. Kiyose, T. Iida, and Z. Morita: Z. Metallkd., 1991, vol. 82, pp. 836–40.

P.W. Peterson, T.Z. Kattamis, and A.F. Giamei: Metall. Trans. A, 1980, vol. 11A, pp. 1059–65.

R. Kadalbal, J.J. Montoya-Cruz, and T.Z. Kattamis: Metall. Trans. A, 1980, vol. 11A, pp. 1547–53.

M.A. Taha and W. Kurz: Z. Metallkd., 1981, vol. 72, pp. 546–49.

C.L. Jeanfils, J.H. Chen, and H.J. Klein: in Modeling of Casting and Welding Processes, H.D. Brody and D. Apelian, eds., TMS-AIME, Warrendale, PA, 1981, pp. 313–32.

L. Ouichou: Ph.D. Thesis, Institut National Polytechnique de Lorraine, Vandoeuvre-les-Nancy, France, 1983.

R. Sellamuthu and A.F. Giamei: Metall. Trans. A, 1986, vol. 17A, pp. 419–28.

T. Tanaka, Z. Morita, and N. Imai: Trans. Iron Steel Inst. Jpn., 1988, vol. 28, p. B-11.

J. Lacaze, A. Chehaibou, and G. Lesoult: Z. Metallkd., 1989, vol. 80, pp. 15–20.

S.N. Tewari, M. Vijayakumar, J.E. Lee, and P.A. Curreri: Mater. Sci. Eng. A, 1991, vol. A141, pp. 97–102.

E. Gozlan, S.F. Dirnfeld, M. Bamberger, J. Klodt, and B. Prinz: Z. Metallkd., 1993, vol. 84, pp. 776–80.

G.I. Rosen, S.F. Dirnfeld, M. Bamberger, and B. Prinz: J. Mater. Sci., 1995, vol. 30, pp. 1379–85.

K.L. Zeisler-Mashl and B.J. Pletka: in Superalloys 1992, S.D. Antolovich, R.W. Stusrud, R.A. MacKay, D.L. Anton, T. Khan, R.D. Kissinger, and D.L. Klarstrom, eds., TMS, Warrendale, PA, 1992, pp. 175–84.

K.L. Zeisler-Mashl: Ph.D. Dissertation, Michigan Technological University, Houghton, MI, 1992.

K.L. Zeisler-Mashl: in Advanced Turbine Systems Materials Workshop, United States Department of Energy, Charleston, SC, Feb. 13–14, 1996.

N. D’Souza, B.A. Shollock, and M. McLean: Proc. 4th Decennial Int. Conf. on Solidification Processing, J. Beech and H. Jones, eds., University of Sheffield, Sheffield, United Kingdom, 1997, pp. 316–20.

U. Grafe, D. Ma, A. Engstrom, and S.G. Fries: in Modeling of Casting, Welding and Advanced Solidification Processes VIII, B.G. Thomas and C. Beckermann, eds., TMS, Warrendale, PA, 1998, pp. 227–34.

A. Kagawa, M. Hirata, and Y. Sakamoto: J. Mater. Sci., 1990, vol. 25, pp. 5063–69.

W.J. Boettinger: “Phase Diagram (Subtask 2.1),” Report to Investment Casting Cooperative Arrangement: Materials Science Based Microstructure Modeling of Multicomponent Superalloys, National Institute of Standards and Technology, Gaithersburg, MD, 1996.

S.-C. Huang: “Solidification Experiments and Foundry Trails (Subtask 3.1),” Report to Investment Casting Cooperative Arrangement: Materials Science Based Microstructure Modeling of Multicomponent Superalloys, General Electric Company, Schenectady, NY, 1998.

N. Saunders: in Superalloy 1996, R.D. Kissinger, D.J. Deye, D.L. Anton, A.D. Cetel, M.V. Nathal, T.M. Pollock, and D.A. Woodford, eds., TMS, Warrendale, PA, 1996, pp. 101–10.

“ProCast™ — Thermo Tech Databases”, Report by AEA Technology, Inc., Bethel Park, PA, 1997.

W.J. Boettinger, U.R. Kattner, and D.K. Banerjee: in Modeling of Casting, Welding and Advanced Solidification Processes VIII, B.G. Thomas and C. Beckermann, eds., TMS, Warrendale, PA, 1998, pp. 159–70.

W.-M. Huang and Y.A. Chang: Intermetallics, 1998, vol. 19, pp. 361–66.

Ternary Alloys: A Comprehensive Compendium of Evaluated Constitutional Data and Phase Diagrams, G. Petzow and G. Effenberg, eds., VCH Publishers, New York, NY, 1993, vol. 7, pp. 483–97.

K.P. Gupta: Phase Diagrams of Ternary Nickel Alloys, Indian Institute of Metals, Calcutta, India, 1990, Part 1, pp. 71–92.

Ternary Alloys: A Comprehensive Compendium of Evaluated Constitutional Data and Phase Diagrams, G. Petzow and G. Effenberg, eds., VCH Publishers, New York, NY, 1991, vol. 4, pp. 400–15.

D.A. Skoog, D.M. West, and F.J. Holler: Fundamentals of Analytical Chemistry, 7th ed., Saunders College Publishing, Philadelphia, PA, 1996, pp. 47–68.

D.B. Rorabacher: Anal. Chem., 1991, vol. 63, pp. 139–46.

R.B. Dean and W.J. Dixon: Anal. Chem., 1951, vol. 23, pp. 636–38.

D.A. Skoog, D.M. West, and F.J. Holler: Fundamentals of Analytical Chemistry, 7th ed., Saunders College Publishing, Philadelphia, PA, 1996, pp. 21–44.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Sung, P.K., Poirier, D.R. Liquid-solid partition ratios in nickel-base alloys. Metall Mater Trans A 30, 2173–2181 (1999). https://doi.org/10.1007/s11661-999-0029-5

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-999-0029-5