Abstract

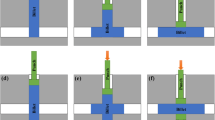

The influence of pressing speed in equal-channel angular (ECA) pressing was investigated using samples of pure Al and an Al-1 pct Mg alloy and a range of pressing speeds from ∼10−2 to ∼10 mm s−1. The results show that the speed of pressing has no significant influence on the equilibrium grain size, at least over the range used in these experiments. Thus, the equilibrium grain sizes were ∼1.2 µm for pure Al and ∼0.5 µm for the Al-1 pct Mg alloy for all pressing conditions. However, it is shown that the nature of the microstructure is dependent on the pressing speed, because recovery occurs more easily at the slower speeds, so that the microstructure is then more equilibrated. There is also indirect evidence for the advent of frictional effects when the cross-sectional dimensions of the samples are at or below ∼5 mm.

Similar content being viewed by others

References

V.M. Segal, V.I. Reznikov, A.E. Drobyshevskiy, and V.I. Kopylov: Russ. Metall. (Metally), 1981, vol. 1, pp. 99–105.

V.M. Segal: Mater. Sci. Eng., 1995, vol. A197, pp. 157–64.

R.Z. Valiev, D.A. Salimonenko, N.K. Tsenev, P.B. Berbon, and T.G. Langdon: Scripta Mater., 1997, vol. 37, pp. 1945–50.

S. Komura, P.B. Berbon, M. Furukawa, Z. Horita, M. Nemoto, and T.G. Langdon: Scripta Mater., 1998, vol. 38, pp. 1851–56.

T.G. Langdon, M. Furukawa, Z. Horita, and M. Nemoto: JOM, 1998, vol. 50 (6), pp. 41–45.

P.B. Berbon, M. Furukawa, Z. Horita, M. Nemoto, N.K. Tsenev, R.Z. Valiev, and T.G. Langdon: Phil. Mag. Lett., 1998, vol. 78, pp. 313–18.

R.Z. Valiev, R.R. Mulyukov, V.V. Ovchinnikov, and V.A. Shabashov: Scripta Metall. Mater., 1991, vol. 25, pp. 2717–22.

Kh.Ya. Mulyukov, S.B. Khaphizov, and R.Z. Valiev: Phys. Status Solidi (a), 1992, vol. 133, pp. 447–54.

N.A. Akhmadeev, N.P. Kobelev, R.R. Mulyukov, Ya.M. Soifer, and R.Z. Valiev: Acta Metall. Mater., 1993, vol. 41, pp. 1041–46.

Y. Iwahashi, Z. Horita, M. Nemoto, and T.G. Langdon: Acta Mater., 1997, vol. 45, pp. 4733–41.

Y. Iwahashi, Z. Horita, M. Nemoto, and T.G. Langdon: Acta Mater., 1998, vol. 46, pp. 3317–31.

A. Gholinia, J.R. Bowen, P.B. Prangnell, and F.J. Humphreys: in Aluminum Alloys: Their Physical and Mechanical Properties, T. Sato, S. Kumai, T. Kobayashi, and Y. Murukami, eds., The Japan Institute of Light Metals, Tokyo, 1998, vol. 1, pp. 577–82.

S. Ferrasse, V.M. Segal, K.T. Hartwig, and R.E. Goforth: Metall. Mater. Trans. A, 1997, vol. 28A, pp. 1047–57.

S. Ferrasse, V.M. Segal, K.T. Hartwig, and R.E. Goforth: J. Mater. Res., 1997, vol. 12, pp. 1253–61.

K. Oh-ishi, Z. Horita, M. Furukawa, M. Nemoto and T.G. Langdon: Metall. Mater. Trans. A, 1998, vol. 29A, pp. 2011–13.

W.H. Huang, M.F. Li, P.W. Kao and C.P. Chang: in The 3rd Pacific Rim Int. Conf. on Advanced Materials and Processing (PRICM 3), M.A. Imam, R. DeNale, S. Hanada, Z. Zhong, and D.N. Lee, eds., TMS, Warrendale, PA, 1998, pp. 1943–48.

M. Furukawa, Y. Iwahashi, Z. Horita, M. Nemoto, and T.G. Langdon: Mater. Sci. Eng., 1998, vol. A257, pp. 328–32.

K. Nakashima, Z. Horia, M. Nemoto, and T.G. Langdon: Acta Mater., 1998, vol. 46, pp. 1589–99.

Y. Iwahashi, Z. Horita, M. Nemoto, and T.G. Langdon: Metall. Mater. Trans. A, 1998, vol. 29A, pp. 2503–10.

M. Furukawa, P.B. Berbon, Z. Horita, M. Nemoto, N.K. Tsenev, R.Z. Valiev, and T.G. Langdon: Metall. Mater. Trans. A, 1998, vol. 29A, pp. 169–77.

P.B. Berbon, N.K. Tsenev, R.Z. Valiev, M. Furukawa, Z. Horita, M. Nemoto, and T.G. Langdon: Metall. Mater. Trans. A, 1998, vol. 29A, pp. 2237–43.

Y. Iwahashi, M. Furukawa, Z. Horita, M. Nemoto, and T.G. Langdon: Metall. Mater. Trans. A, 1998, vol. 29A, pp. 2245–52.

Y. Iwahashi, J. Wang, Z. Horita, M. Nemoto, and T.G. Langdon: Scripta Mater., 1996, vol. 35, pp. 143–46.

B. Bay and N. Hansen: in Deformation of Polycrystals: Mechanisms and Microstructures, N. Hansen, A. Horsewell, T. Leffers, and H. Lilholt, eds., Risø National Laboratory, Roskilde, Denmark, 1981, pp. 137–44.

C.Y.J. Barlow, B. Bay, and N. Hansen: Phil. Mag. A, 1985, vol. 51, pp. 253–75.

B. Bay and N. Hansen: in Annealing Processes: Recovery, Recrystallization and Grain Growth, N. Hansen, D. Juul Jensen, T. Leffers, and B. Ralph, eds., Risø National Laboratory, Roskilde, Denmark, 1986, pp. 215–20.

Y. Wu and I. Baker: Scripta Mater., 1997, vol. 37, pp. 437–42.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Berbon, P.B., Furukawa, M., Horita, Z. et al. Influence of pressing speed on microstructural development in equal-channel angular pressing. Metall Mater Trans A 30, 1989–1997 (1999). https://doi.org/10.1007/s11661-999-0009-9

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-999-0009-9