Abstract

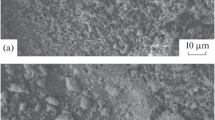

Particulate TiB2 reinforced aluminum-based metal matrix composites (MMCs) were successfully fabricated by means of the reaction processing method. TiB2 particulates were formed in situ through the reaction of Ti and B in Ti-Al-B, TiO2 and B in TiO2-Al-B, and TiO2 and B2O3 in TiO2-Al-B2O3 systems. The results showed that in situ TiB2 particulates formed in the Ti-Al-B system had a size of 5 µm and they exhibited block and rodlike structures. Moreover, coarse Al3Ti blocks several tens of micrometers in size were also formed simultaneously. On the other hand, equiaxed Al2O3 and TiB2 particulates with a size of less than 2 µm were formed in situ in the TiO2-Al-B and TiO2-Al-B2O3 systems. The Al3Ti phase was completely eliminated in the TiO2-Al-B system with increasing B content. Tensile tests revealed that the Al2O3 · TiB2/Al composite fabricated from the TiO2-Al-B system exhibits excellent mechanical properties. The yield strength of the Al2O3 · TiB2/Al composite appeared to increase with increasing TiB2 content. The yield strength of the Al2O3 · TiB2/Al composite could be further increased by introducing CuO into the TiO2-Al-B system. Such an increment in mechanical strength arose from the strengthening effect caused by the Al2Cu precipitates. The incorporation of CuO had no effect on the in situ reaction process of the TiO2-Al-B system. Finally, the effect of SiC addition on the microstructure and mechanical properties of the composites fabricated from the TiO2-Al-B and TiO2-Al-B-CuO systems was also investigated.

Similar content being viewed by others

References

S.V. Nair, J.K. Tien, and R.C. Bates: Int. Met. Rev., 1985, vol. 10, pp. 275–90.

P.M. Singh and J.J. Lewandowski: Metall. Trans. A, 1993, vol. 24A, pp. 2531–43.

T.J. Sutherland, P.B. Hoffman, and J.C. Gibeling: Metall. Trans. A, 1994, vol. 25A, pp. 2453–60.

M.K. Aghajanian, M.A. Rocazella, J.T. Burke, and S.D. Reck: J. Mater. Sci., 1991, vol. 26, pp. 447–54.

A.K. Kuruvilla, V.V. Bhanuprasad, K.S. Prasad, and Y.R. Mahajan: Bull. Mater. Sci., 1989, vol. 12, pp. 495–505.

M. Roy, B. Venkatraman, V.V. Bhanuprasad, K.S. Prasad, and G. Sundarajan: Metall. Trans. A, 1992, vol. 23A, pp. 2833–47.

K. Satyaprasad, Y.R. Mahajan, and V.V. Bhanuprasad: Scripta Metall. Mater., 1992, vol. 26, pp. 711–16.

T.G. Nieh and R.F. Karlak: Scripta Metall. Mater., 1984, vol. 18, pp. 25–28.

R.K. Everett and P.L. Higby: Scripta Metall. Mater., 1991, vol. 25, pp. 625–30.

M. Mabuchi, K. Igashi, Y. Okada, S. Tanimura, T. Imai, and K. Kubo: Scripta Metall. Mater., 1991, vol. 25, pp. 2517–22.

M. Mabuchi, K. Igashi, K. Inoue, and S. Tanimura: Scripta Metall. Mater., 1992, vol. 26, pp. 1839–44.

T.R. McNelley and P.N. Kalu: Scripta Metall. Mater., 1991, vol. 25, pp. 1041–46.

J. Wang, M. Furakuwa, Z. Horita, M. Nemoto, Y. Ma, and T.G. Langdon: Metall. Trans. A, 1995, vol. 26A, pp. 581–87.

A.R.C. Westwood: Metall. Trans. A, 1988, vol. 19A, pp. 749–58.

M.J. Kozak and K.S. Kumar: U.S. Patent 4,808,372, 1989.

P. Sahoo and M.J. Kozak: Mater. Sci. Eng., 1991, vol. A131, pp. 69–76.

M.K. Prekumar and M.G. Chu: Mater. Sci. Eng., 1995, vol. A202, pp. 172–78.

P.C. Maity, S.C. Panigrahi, and P.N. Chakraborty: Scripta Metall. Mater., 1993, vol. 28, pp. 549–52.

H. Nakata, T. Choh, and N. Kanetake: J. Mater. Sci., 1995, vol. 30, pp. 1719–27.

J.V. Wood, P. Davies, and J.L.F. Kellie: Mater. Sci. Technol., 1993, vol. 9, pp. 833–37.

Y. Chen and D.D.L. Chung: J. Mater. Sci., 1996, vol. 31, pp. 311–15.

F. Olevsky, P. Mogilevsky, E.Y. Gutmanas, and I. Gotman: Metall. Trans. A, 1996, vol. 27A, pp. 2071–79.

A.K. Kuruvilla, K.S. Prasad, V.V. Bhanuprasad, and Y.R. Mahajan: Scripta Metall. Mater., 1990, vol. 24, pp. 873–78.

A.B. Pandey, R.S. Mishra, and Y.R. Mahajan: Mater. Sci. Eng., 1994, vol. A189, pp. 95–104.

Z.Y. Ma, J. Bi, Y.X. Lu, H.W. Shen, and Y.X. Gao: Composite Interface, 1991, vol. 1, pp. 287–91.

Z.Y. Ma, J.H. Li, M. Luo, X.G. Ning, Y.X. Lu, J. Bi, and Y.Z. Zhang: Scripta Metall. Mater., 1994, vol. 31, pp. 635–39.

Z.Y. Ma, J.H. Li, S.X. Li, X.G. Ning, Y.X. Lu, and J. Bi: J. Mater. Sci., 1996, vol. 31, pp. 741–47.

D.Z. Wang, Z.Y. Liu, C.K. Yao, and M. Yao: Mater. Sci. Progr. 1993, vol. 7, pp. 457–60 (in Chinese).

Y. Chen and D.D.L. Chung: J. Mater. Sci., 1995, vol. 30, pp. 4609–16.

G.M. Vyletel, J.E. Allison, and D.C.V. Aken: Metall. Trans. A, 1993, vol. 24A, pp. 2545–57.

V.V. Bhanuprasad: Int. J. Powder, 1991, vol. 27, pp. 227–31.

Z.Y. Ma, J. Bi, Y.X. Lu, M. Luo, and Y.X. Gao: Scripta Metall. Mater., 1993, vol. 29, pp. 225–29.

R. Arsenault: Mater. Sci. Eng., 1984, vol. 64, pp. 171–81.

E. Orowan: Symp. on Internal Stress in Metals and Alloys, Institute of Metals, London, 1948, p. 451.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Ma, Z.Y., Tjong, S.C. In Situ ceramic particle-reinforced aluminum matrix composites fabricated by reaction pressing in the TiO2 (Ti)-Al-B (B2O3) systems. Metall Mater Trans A 28, 1931–1942 (1997). https://doi.org/10.1007/s11661-997-0123-5

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-997-0123-5