Abstract

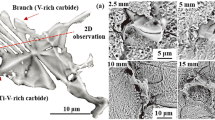

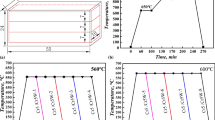

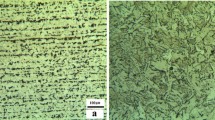

In this study, the thermal stability of H13 hot-work tool steel was significantly improved through the use of nitrogen as a substitute for carbon. The results indicated that the 0.3C-0.2N and 0.2C-0.3N steels exhibited better hardness stability than H13 steel (0.4C-0N). In particular, the 0.2C-0.3N steel exhibited substantially improved hardness stability. The softening resistance mechanism was revealed from the perspectives of precipitates, dislocations, laths, and variants through first-principles calculations, thermodynamic and kinetic models, and variant reconstruction. First, for precipitate stability, the results of first-principles calculations and kinetic analysis showed that substituting N with C reduced the formation energy of carbides and facilitated the formation of carbonitrides. For 0.2C-0.3N steel, which had the highest activation energy, both the diffusion of alloying elements and the coarsening of carbonitrides were significantly inhibited. Second, in terms of dislocation evolution, the most stable lattice constant, highest interstitial atom content and lowest carbide precipitation content were the keys to inhibiting dislocation recovery. Finally, the dislocation and heat-induced boundary migration stimulated the selection of variants, resulting in the coarsening and coalescence of laths. The change from V17 to V1 variant pairs was dominant for the lath coalescence of 0.2C-0.3N steel.

Similar content being viewed by others

References

H.N. Ding, X.N. Cheng, T. Liu, F.Y. Cao, L.L. Chen, R. Luo, Y.X. Zhang, and B.S. Zhang: Mater. Sci. Eng. A, 2022, vol. 842, 143102. https://doi.org/10.1016/j.msea.2022.143102.

H.J. Wang, H.B. Li, H. Feng, W.C. Jiao, H.C. Zhu, S.C. Zhang, and Z.H. Jiang: Mater. Charact., 2023, vol. 203, 113154. https://doi.org/10.1016/j.matchar.2023.113154.

A. Jilg and T. Seifert: Mater. Sci. Eng. A, 2018, vol. 721, pp. 96–102. https://doi.org/10.1016/j.msea.2018.02.048.

J. Zhu, G.T. Lin, Z.H. Zhang, and J.X. Xie: Mater. Sci. Eng. A, 2020, vol. 797, 140139. https://doi.org/10.1016/j.msea.2020.140139.

J. Zhu, Z.H. Zhang, and J.X. Xie: Mater. Sci. Eng. A, 2019, vol. 752, pp. 101–14. https://doi.org/10.1016/j.msea.2019.02.085.

N.Y. Du, H.W. Liu, P.X. Fu, H.H. Liu, C. Sun, Y.F. Cao, and D.Z. Li: Crystals, 2020, vol. 10, p. 238. https://doi.org/10.3390/cryst10040238.

G. Krauss: Steel Res. Int., 2017, vol. 88, p. 1700038. https://doi.org/10.1002/srin.201700038.

S.W. Young, M. Sato, K. Yamamitsu, Y. Shimada, Y.J. Zhang, G. Miyamoto, and T. Furuhara: Acta Mater., 2021, vol. 206, 116612. https://doi.org/10.1016/j.actamat.2020.116612.

Y.W. Chen, B.M. Huang, Y.T. Tsai, S.P. Tsai, C.Y. Chen, and J.R. Yang: Mater. Charact., 2017, vol. 131, pp. 298–305. https://doi.org/10.1016/j.matchar.2017.07.022.

J.L. Tian, K. Chen, H.B. Li, and Z.H. Jiang: Mater. Sci. Eng. A, 2022, vol. 833, 142529. https://doi.org/10.1016/j.msea.2021.142529.

Z.J. Zhang, J.S. Zhang, Z.H. Yao, G.L. Xie, Y. Lian, M.Y. Ma, C. Zhao, and J.F. Huang: Metals, 2019, vol. 9, p. 805. https://doi.org/10.3390/met9070805.

S. Li, X.C. Wu, S.H. Chen, and J.W. Li: J. Mater. Eng. Perform., 2016, vol. 25, pp. 2993–3006. https://doi.org/10.1007/s11665-016-2124-2.

R.M. Wu, W. Li, M. Chen, S. Huang, and T. Hu: Mater. Sci. Eng. A, 2021, vol. 812, 141140. https://doi.org/10.1016/j.msea.2021.141140.

H. Feng, H.B. Li, J. Dai, Y. Han, J.D. Qu, Z.H. Jiang, Y. Zhao, and T. Zhang: Corros. Sci., 2022, vol. 204, 110396. https://doi.org/10.1016/j.corsci.2022.110396.

H. Feng, H.B. Li, W.C. Jiao, Z.H. Jiang, M.H. Cai, H.C. Zhu, and Z.G. Chen: Metall. Mater. Trans. A, 2019, vol. 50A, pp. 4987–99. https://doi.org/10.1007/s11661-019-05398-4.

H.B. Li, Y. Han, H. Feng, G. Zhou, Z.H. Jiang, M.H. Cai, Y.Z. Li, and M.X. Huang: J. Mater. Sci. Technol., 2023, vol. 141, pp. 184–92. https://doi.org/10.1016/j.jmst.2022.09.020.

J.B. Gu, J.Y. Li, J. Yanagimoto, W. Li, and L.H. Li: Mater. Sci. Eng. A, 2021, vol. 804, 140721. https://doi.org/10.1016/j.msea.2020.140721.

J.B. Gu, H.Q. Liu, J.Y. Li, Y.B. Jiang, and R.J. Chang: J. Iron. Steel Res. Int., 2019, vol. 26, pp. 483–89. https://doi.org/10.1007/s42243-018-0164-6.

N.H. van Dijk, A.M. Butt, L. Zhao, J. Sietsma, S.E. Offerman, J.P. Wright, and S. van der Zwaag: Acta Mater., 2005, vol. 53, pp. 5439–47. https://doi.org/10.1016/j.actamat.2005.08.017.

M. Karam Abian, A. Zarei Hanzaki, H.R. Abedi, and S. Heshmati Manesh: Mater. Sci. Eng. A, 2016, vol. 651, pp. 233–40. https://doi.org/10.1016/j.msea.2015.10.116.

F. Niessen, T. Nyyssonen, A.A. Gazder, and R. Hielscher: J. Appl. Crystallogr., 2022, vol. 55, pp. 180–94. https://doi.org/10.1107/S1600576721011560.

Hongzhiwei Technology, Device Studio, version 2021A. 2021. Accessed on 2020.10. https://iresearch.net.cn/cloudSoftware.

P.E. Blöchl: Phys. Rev. B, 1994, vol. 50, p. 17953. https://doi.org/10.1103/PhysRevB.50.17953.

Z. Zhang, D. Delagnes, and G. Bernhart: Mater. Sci. Eng. A, 2004, vol. 380, pp. 222–30. https://doi.org/10.1016/j.msea.2004.03.067.

E. Virtanen, C.J. Van Tyne, B.S. Levy, and G. Brada: J. Mater. Process. Technol., 2013, vol. 213, pp. 1364–69. https://doi.org/10.1016/j.jmatprotec.2013.03.003.

R. Gecu: Mater. Chem. Phys., 2022, vol. 292, 126802. https://doi.org/10.1016/j.matchemphys.2022.126802.

C.S. Li, Y.H. Han, E. Li, S. He, and J.Y. Ren: J. Mater. Eng. Perform., 2022, vol. 31, pp. 4983–97. https://doi.org/10.1007/s11665-021-06303-0.

A.G. Ning, Y. Liu, R. Gao, S. Yue, M.B. Wang, and H.J. Guo: JOM, 2021, vol. 73, pp. 2194–2202. https://doi.org/10.1007/s11837-021-04694-y.

J.B. Gu, J.Y. Li, and J.H. Huo: Steel Res. Int., 2017, vol. 88, p. 1700031. https://doi.org/10.1002/srin.201700031.

X.G. Zhang, K. Matsuura, and M. Ohno: Metall. Mater. Trans. A, 2014, vol. 45A, pp. 4623–34. https://doi.org/10.1007/s11661-014-2364-4.

C. Zhang, Y.Q. Cao, J.Y. Chen, H.Y. Ye, C. Zhao, and J.F. Huang: Steel Res. Int., 2023, vol. 94, p. 2200811. https://doi.org/10.1002/srin.202200811.

Q.C. Zhou, X.C. Wu, N.N. Shi, J.W. Li, and N. Min: Mater. Sci. Eng. A, 2011, vol. 528, pp. 5696–5700. https://doi.org/10.1016/j.msea.2011.04.024.

N. Sargent, Y.K. Wang, D.Z. Li, Y.H. Zhao, X. Wang, and W. Xiong: Addit. Manuf. Lett., 2023, vol. 6, 100133. https://doi.org/10.1016/j.addlet.2023.100133.

H.N. Ding, T. Liu, J.B. Wei, L. Chen, F.Y. Cao, B.S. Zhang, R. Luo, and X.N. Cheng: Mater. Design, 2022, vol. 224, 111317. https://doi.org/10.1016/j.matdes.2022.111317.

J.H. Jang, C.H. Lee, Y.U. Heo, and D.W. Suh: Acta Mater., 2012, vol. 60, pp. 208–17. https://doi.org/10.1016/j.actamat.2011.09.051.

P.H. Yang, H.G. Fu, X.Y. Guo, B. Rachid, and J. Lin: J. Mater. Res. Technol., 2020, vol. 9, pp. 3109–20. https://doi.org/10.1016/j.jmrt.2020.01.056.

Y.L. Wang, K.X. Song, and Y.M. Zhang: Mater. Res. Express, 2019, vol. 6, 096513. https://doi.org/10.1088/2053-1591/ab2bb9.

J.Y. Li, Y.L. Chen, and J.H. Huo: Mater. Sci. Eng. A, 2015, vol. 640, pp. 16–23. https://doi.org/10.1016/j.msea.2015.05.006.

S. Morito, X. Huang, T. Furuhara, T. Maki, and N. Hansen: Acta Mater., 2006, vol. 54, pp. 5323–31. https://doi.org/10.1016/j.actamat.2006.07.009.

S. Morito, H. Tanaka, R. Konishi, T. Furuhara, and T. Maki: Acta Mater., 2003, vol. 51, pp. 1789–99. https://doi.org/10.1016/S1359-6454(02)00577-3.

G. Miyamoto, N. Iwata, N. Takayama, and T. Furuhara: Acta Mater., 2010, vol. 58, pp. 6393–6403. https://doi.org/10.1016/j.actamat.2010.08.001.

Acknowledgments

This research was sponsored by the National Natural Science Foundation of China [Grant Nos. 52374331, 52325406 and U1960203], Science Fund for Distinguished Young Scholars of Liaoning Province [Grant No. 2023JH6/100500008], and Program of Introducing Talents of Discipline to Universities [Grant No. B21001]. Special thanks are due to the instrumental analysis from Analytical and Testing Centre, Northeastern University. The authors gratefully acknowledge HZWTECH for providing computation facilities.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, HJ., Feng, H., Li, HB. et al. Nitrogen-Substituting Carbon Significantly Improves Softening Resistance of H13 Hot-Work Die Steel. Metall Mater Trans A (2024). https://doi.org/10.1007/s11661-024-07367-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11661-024-07367-y