Abstract

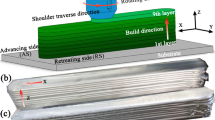

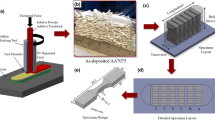

Multilayer AA6061 aluminum alloy components are successfully fabricated by the additive friction stir deposition (AFSD) process. The surface morphology, microstructure, and mechanical property are investigated to evaluate the quality of AFSD-deposited AA6061 alloy. The surface of the final AFSD-deposited samples is relatively smooth, and the average surface roughness (Sa) is 2.490 μm. The recrystallized grains recovered dynamically under the action of high thermal cycling. Grain nucleation and directional growth in the layer–layer interface increase the proportion of HAGBs. Many blocky and rod-like AlFeSi phases can be seen in the AFSD-deposited layer. The cross-sectional microhardness of AFSD-deposited AA6061 alloy shows gradient characteristics. The minimum value of microhardness appeared in the interface between the substrate and the 1st layer. The maximum value of ultimate tensile strength of the 3rd layer samples without interface can reach 308 MPa with elongation at break of approximately 32.6 pct. The present work provides a pathway for solid-state additive manufacturing of light alloy parts.

Similar content being viewed by others

References

C.C. Roth, T. Tancogne-Dejean, and D. Mohr: Addit. Manuf., 2021, vol. 43, p. 101998.

L. Chen, Y. Sun, L. Li, and X. Ren: Mater. Sci. Eng. A, 2020, vol. 792, p. 139655.

L. Chen, Y. Sun, L. Li, and X. Ren: Corros. Sci., 2020, vol. 169, p. 108606.

L. Chen, P. Gu, T. Ge, Y. Sun, L. Li, and X. Ren: Mater. Sci. Eng. A, 2022, vol. 835, p. 142610.

Y. Wang, M. Hao, J. Wang, M. Li, Z. Gu, C. Meng, R. Deng, and Y. Sun: J. Manuf. Process., 2023, vol. 95, pp. 27–37.

A. Tridello, J. Fiocchi, C.A. Biffi, M. Rossetto, A. Tuissi, and D.S. Paolino: Int. J. Fatigue, 2022, vol. 160, p. 106825.

A. Majeed, A. Ahmed, A. Salam, and M.Z. Sheikh: Int. J. Lightweight Mater. Manuf., 2019, vol. 2, pp. 288–95.

E. Louvis, P. Fox, and C.J. Sutcliffe: J. Mater. Process. Technol., 2011, vol. 211, pp. 275–84.

O.G. Rivera, P.G. Allison, J.B. Jordon, O.L. Rodriguez, L.N. Brewer, Z. McClelland, W.R. Whittington, D. Francis, J. Su, R.L. Martens, and N. Hardwick: Mater. Sci. Eng. A, 2017, vol. 694, pp. 1–9.

H.Z. Yu, M.E. Jones, G.W. Brady, R.J. Griffiths, D. Garcia, H.A. Rauch, C.D. Cox, and N. Hardwick: Scripta Mater., 2018, vol. 153, pp. 122–30.

H.Z. Yu and R.S. Mishra: Mater. Res. Lett., 2021, vol. 9, pp. 71–83.

R.J. Griffiths, D. Garcia, J. Song, V.K. Vasudevan, M.A. Steiner, W. Cai, and H.Z. Yu: Materialia, 2021, vol. 15, p. 100967.

C.J.T. Mason, R.I. Rodriguez, D.Z. Avery, B.J. Phillips, B.P. Bernarding, M.B. Williams, S.D. Cobbs, J.B. Jordon, and P.G. Allison: Addit. Manuf., 2021, vol. 40, p. 101879.

B.J. Phillips, D.Z. Avery, T. Liu, O.L. Rodriguez, C.J.T. Mason, J.B. Jordon, L.N. Brewer, and P.G. Allison: Materialia, 2019, vol. 7, p. 100387.

S.C. Beck, B.A. Rutherford, D.Z. Avery, B.J. Phillips, H. Rao, M.Y. Rekha, L.N. Brewer, P.G. Allison, and J.B. Jordon: Mater. Sci. Eng. A, 2021, vol. 819, p. 141351.

D.Z. Avery, B.J. Phillips, C.J.T. Mason, M. Palermo, and J.B. Jordon: Metall. Mater. Trans. A, 2020, vol. 51A, pp. 1–18.

G.G. Stubblefield, K. Fraser, B.J. Phillips, J.B. Jordon, and P.G. Allison: Mater. Des., 2021, vol. 202, p. 109514.

B.J. Phillips, C. Mason, S.C. Beck, D.Z. Avery, and J.B. Jordon: J. Mater. Process. Technol., 2021, vol. 295, p. 117169.

S. Babaniaris, L. Jiang, R.K. Varma, E. Farabi, T. Dorin, M. Barnett, and D. Fabijanic: Addit. Manuf. Lett., 2022, vol. 3, p. 100096.

P. Agrawal, R.S. Haridas, P. Agrawal, and R.S. Mishra: Addit. Manuf., 2022, vol. 60, p. 103282.

M. Hajian, A. Abdollah-zadeh, S.S. Rezaei-Nejad, H. Assadi, S.M.M. Hadavi, K. Chung, and M. Shokouhimehr: Mater. Des., 2015, vol. 67, pp. 82–94.

B. Du, X. Yang, K. Liu, Z. Sun, and D. Wang: Weld. World, 2019, vol. 63, pp. 989–1000.

W. Tang, X. Yang, C. Tian, and Y. Xu: Mater Charact, 2023, vol. 196, p. 112646.

Y. Aruga, M. Kozuka, Y. Takaki, and T. Sato: Metall. Mater. Trans. A, 2014, vol. 45A, pp. 5906–13.

V. Fallah, B. Langelier, N. Ofori-Opoku, B. Raeisinia, N. Provatas, and S. Esmaeili: Acta Mater., 2016, vol. 103, pp. 290–300.

J.K. Sunde, C.D. Marioara, A.V. Helvoort, and R. Holmestad: Mater Charact, 2018, vol. 142, pp. 458–69.

H.-W. Son, J.-Y. Lee, Y.-H. Cho, J.-I. Jang, S.-B. Kim, and J.-M. Lee: J. Alloy. Compd., 2023, vol. 960, p. 170982.

H. Shishido, Y. Aruga, Y. Murata, C.D. Marioara, and O. Engler: J. Alloy. Compd., 2022, vol. 927, p. 166978.

H. Zhao, Q. Pan, Q. Qin, Y. Wu, and X. Su: Mater. Sci. Eng. A, 2019, vol. 751, pp. 70–79.

H. Beladi, E. Farabi, P.D. Hodgson, G.S. Rohrer, M.R. Barnett, and D. Fabijanic: Philos. Mag., 2022, vol. 102, pp. 618–33.

F. Montheillet, M. Cohen, and J.J. Jonas: Acta Metall., 1984, vol. 32, pp. 2077–89.

Y. Peng, B. Huang, Y. Zhong, C. Su, Z. Tao, X. Rong, Z. Li, and H. Tang: Corros. Sci., 2023, vol. 215, p. 111029.

Y. Zhang, J. Jiang, Y. Wang, G. Xiao, Y. Liu, and M. Huang: J. Alloys Compd., 2022, vol. 893, p. 162311.

A. Sabard and T. Hussain: J. Mater. Sci., 2019, vol. 54, pp. 12061–78.

V. Gopan, K. Wins, and A. Surendran: CIRP J. Manuf. Sci. Technol., 2021, vol. 32, pp. 228–48.

C.I. Chang, C.J. Lee, and J.C. Huang: Scripta Mater., 2004, vol. 51, pp. 509–14.

P. Asadi, M.K. Besharati Givi, and M. Akbari: Int. J. Adv. Manuf. Technol., 2016, vol. 83, pp. 301–11.

B. Bagheri, A. Abdollahzadeh, M. Abbasi, and A.H. Kokabi: Int.J. Mater. Form., 2021, vol. 14, pp. 623–40.

H. Mirzadeh: Mater. Sci. Eng. A, 2021, vol. 819, p. 141499.

L. Ritti and T. Bhat: Mater. Today Proc., 2021, vol. 46, pp. 2489–97.

B.M. Darras: J. Mater. Eng. Perform., 2012, vol. 21, pp. 1–6.

H. Li, S. Yang, S. Zhang, B. Zhang, Z. Jiang, H. Feng, P. Han, and J. Li: Mater. Des., 2017, vol. 118, pp. 207–17.

B. Wang, P. Zhu, Y. Cao, L. Zhou, P. Xue, and L. Wu: J. Market. Res., 2023, vol. 26, pp. 6096–6107.

S. Kilic, F. Ozturk, and M.F. Demirdogen: J. Eng. Res., 2023, https://doi.org/10.1016/j.jer.2023.09.005.

K.V. Mjali and Z.A. Mkoko: Manuf. Lett., 2023, vol. 35, pp. 305–13.

V. Venugopal, V. Pratap Singh, and B. Kuriachen: Mater. Today, 2023, https://doi.org/10.1016/j.matpr.2023.07.182.

Acknowledgments

The authors are grateful to the projects supported by the Youth Science Foundation of Jiangsu Province (Grant No. BK20210754), the Natural Science Foundation for Post-doctoral Scientists of China (Grant No. 2021M101519), and the Natural Science Foundation of China (Grant No. U21A20138, 51975261).

Data Availability

Data will be made available on request.

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chen, L., Lu, L., Zhu, L. et al. Microstructure Evolution and Mechanical Properties of Multilayer AA6061 Alloy Fabricated by Additive Friction Stir Deposition. Metall Mater Trans A 55, 1049–1064 (2024). https://doi.org/10.1007/s11661-024-07303-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-024-07303-0