Abstract

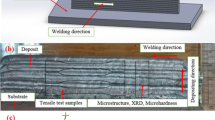

In the present work, aluminum-5356 alloy was deposited using wire arc additive manufacturing (WAAM) equipped with a robotic gas metal arc welding setup (GMAW). The morphology, microhardness, microstructure, and tribological features of the WAAM-deposited specimen were studied in detail. The results show that the microhardness of the WAAM-deposited Al-5356 alloy increased from 57 to 81 HV from the top to the bottom portion. The wear resistance of the deposited component also increased from the top to the bottom portion. Moreover, the microstructure and mechanical properties of the deposited wall were investigated on deposited specimens with selected parameters from the top to bottom area of specimens, respectively. The detailed study shows the understanding of the effect of variation in current on the surface morphology, microstructure, hardness, and wear behavior of different areas from top to bottom of the deposited multilayer components.

Similar content being viewed by others

Reference

T. DebRoy, H.L. Wei, J.S. Zuback, T. Mukherjee, J.W. Elmer, J.O. Milewski, A.M. Beese, A. de Wilson-Heid, A. De, and W. Zhang, Additive Manufacturing of Metallic Components-Process, Structure and Properties, Prog. Mater. Sci., 2018, 92, p 112–224.

J. Donoghue, A.A. Antonysamy, F. Martina, P.A. Colegrove, S.W. Williams, and P.B. Prangnell, The Effectiveness of Combining Rolling Deformation with Wire-Arc Additive Manufacture on β-Grain Refinement and Texture Modification in Ti-6Al-4V, Mater. Charact., 2016, 114, p 103–114. https://doi.org/10.1016/j.matchar.2016.02.001

B.A. Szost, S. Terzi, F. Martina, D. Boisselier, A. Prytuliak, T. Pirling, M. Hofmann, and D.J. Jarvis, A Comparative Study of Additive Manufacturing Techniques: Residual Stress and Microstructural Analysis of CLAD and WAAM Printed Ti–6Al–4V Components, Mater. Des., 2016, 89, p 559–567. https://doi.org/10.1016/j.matdes.2015.09.115

A. Gomez Ortega, L. Corona Galvan, F. Deschaux-Beaume, B. Mezrag, and S. Rouquette, Effect of Process Parameters on the Quality of Aluminium Alloy Al5Si Deposits in Wire and Arc Additive Manufacturing Using a Cold Metal Transfer Process, Sci. Technol. Weld. Join., 2018, 23(4), p 316–332. https://doi.org/10.1080/13621718.2017.1388995

X. Xu, J. Ding, S. Ganguly, C. Diao, and S. Williams, Oxide Accumulation Effects on Wire+Arc Layer-by-Layer Additive Manufacture Process, J. Mater. Process. Technol., 2018, 252, p 739–750. https://doi.org/10.1016/j.jmatprotec.2017.10.030

C.V. Haden, G. Zeng, F.M. Carter, C. Ruhl, B.A. Krick, and D.G. Harlow, Wire and Arc Additive Manufactured Steel: Tensile and Wear Properties, Addit. Manuf., 2017, 16, p 115–123.

J. Xiong, Z. Yin, and W. Zhang, Closed-Loop Control of Variable Layer Width for Thin-Walled Parts in Wire and Arc Additive Manufacturing, J. Mater. Process. Technol., 2016, 233, p 100–106. https://doi.org/10.1016/j.jmatprotec.2016.02.021

K.H. Kazmi, S.K. Sharma, A.K. Das, A. Mandal, and A. Shukla, Development of Wire Arc Additive Manufactured Cu-Si Alloy: Study of Microstructure and Wear Behavior, J. Mater. Eng. Perform., 2023, 33(1), p 110. https://doi.org/10.1007/s11665-023-07972-9

M. Anand and A.K. Das, Grain Refinement in Wire-Arc Additive Manufactured Inconel 82 Alloy Through Controlled Heat Input, J. Alloys Compd., 2022, 929, p 166949.

B. Mezrag, F. Deschaux-Beaume, and M. Benachour, Control of Mass and Heat Transfer for Steel/Aluminium Joining Using Cold Metal Transfer Process, Sci. Technol. Weld. Join., 2015, 20(3), p 189–198. https://doi.org/10.1179/1362171814Y.0000000271

M. Anand, H. Bishwakarma, N. Kumar, K. Ujjwal, and A.K. Das, Fabrication of Multilayer Thin Wall by WAAM Technique and Investigation of Its Microstructure and Mechanical Properties, Mater. Today Proc., 2022, 56, p 927–930.

S.K. Sharma and C. Sharma, Processing Techniques, Microstructural and Mechanical Properties of Wire Arc Additive Manufactured Stainless Steel: A Review, J. Inst. Eng. Ser. C, 2022, 31, p 1–15.

H.Y. Nie, Z.Y. Yunpeng, P. Zhang, X. Wu, and G. Li, Rapid Prototyping of 4043 Al-Alloy Parts by Cold Metal Transfer, Sci. Technol. Weld. Join., 2018, 23(6), p 527–535.

H. Geng, J. Li, J. Xiong, and X. Lin, Optimisation of Interpass Temperature and Heat Input for Wire and Arc Additive Manufacturing 5A06 Aluminium Alloy, Sci. Technol. Weld. Join., 2017, 22(6), p 472–483. https://doi.org/10.1080/13621718.2016.1259031

K. Ujjwal, M. Anand, H. Bishwakarma, and A.K. Das, Effect of Clamping Position on the Residual Stress in Wire Arc Additive Manufacturing, Int. J. Mater. Res., 2023, 114(10–11), p 872.

A.W. AlShaer, L. Li, and A. Mistry, The Effects of Short Pulse Laser Surface Cleaning on Porosity Formation and Reduction in Laser Welding of Aluminium Alloy for Automotive Component Manufacture, Opt. Laser Technol., 2014, 64, p 162–171. https://doi.org/10.1016/j.optlastec.2014.05.010

G. Gou, M. Zhang, H. Chen, J. Chen, P. Li, and Y.P. Yang, Effect of Humidity on Porosity, Microstructure, and Fatigue Strength of A7N01S-T5 Aluminum Alloy Welded Joints in High-Speed Trains, Mater. Des., 2015, 85, p 309–317. https://doi.org/10.1016/j.matdes.2015.06.177

K.H. Kazmi, A.K. Das, S.K. Sharma, A. Mandal, and A.K. Shukla, Wire Arc Additive Manufacturing of ER-4043 Aluminum Alloy: Evaluation of Bead Profile, Microstructure, and Wear Behavior, Weld. World, 2023, 67(9), p 2187.

K.H. Kazmi, S.K. Sharma, A.K. Das, A. Mandal, A. Kumar Shukla, and R. Mandal, Wire Arc Additive Manufacturing of ER-4043 Aluminum Alloy: Effect of Tool Speed on Microstructure, Mechanical Properties and Parameter Optimization, J. Mater. Eng. Perform., 2023, 23, p 1–4. https://doi.org/10.1007/s11665-023-08309-2

S. Mohanty, S. Basak, D. Saran, K. Chatterjee, T. Datta, A. Kumar, C. Prakash, D.M. Chun, S.T. Hong, and K.K. Sahu, Advanced Surface Engineering Approaches for Exotic Applications, Int. J. Precis. Eng. Manuf., 2023, 9, p 1–33. https://doi.org/10.1007/s12541-023-00870-z

T. Rubben, R.I. Revilla, and I. De Graeve, Influence of Heat Treatments on the Corrosion Mechanism of Additive Manufactured AlSi10Mg, Corros. Sci., 2019, 147, p 406–415. https://doi.org/10.1016/j.corsci.2018.11.038

M. Cabrini, S. Lorenzi, T. Pastore, S. Pellegrini, E.P. Ambrosio, F. Calignano, D. Manfredi, M. Pavese, and P. Fino, Effect of Heat Treatment on Corrosion Resistance of DMLS AlSi10Mg Alloy, Electrochim. Acta, 2016, 206, p 346–355. https://doi.org/10.1016/j.electacta.2016.04.157

A.S. Leon and E.A. Avi, Corrosion Behavior of AlSi10Mg Alloy Produced by Additive Manufacturing (AM) vs. Its Counterpart Gravity Cast Alloy, Metals (Basel), 2016, 148(6), p 1–9.

E. Brandl, U. Heckenberger, V. Holzinger, and D. Buchbinder, Additive Manufactured AlSi10Mg Samples Using Selective Laser Melting (SLM): Microstructure, High Cycle Fatigue, and Fracture Behavior, Mater. Des., 2012, 34, p 159–169. https://doi.org/10.1016/j.matdes.2011.07.067

M. Tang and P.C. Pistorius, Oxides, Porosity and Fatigue Performance of AlSi10Mg Parts Produced by Selective Laser Melting, Int. J. Fatigue, 2017, 94, p 192–201. https://doi.org/10.1016/j.ijfatigue.2016.06.002

Q. Tan, J. Zhang, Q. Sun, Z. Fan, G. Li, Y. Yin, Y. Liu, and M.-X. Zhang, Inoculation Treatment of an Additively Manufactured 2024 Aluminium Alloy with Titanium Nanoparticles, Acta Mater., 2020, 196, p 1–16. https://doi.org/10.1016/j.actamat.2020.06.026

N.T. Aboulkhair, M. Simonelli, L. Parry, I. Ashcroft, C. Tuck, and R. Hague, 3D Printing of Aluminium Alloys: Additive Manufacturing of Aluminium Alloys Using Selective Laser Melting, Prog. Mater. Sci., 2019, 106, p 100578. https://doi.org/10.1016/j.pmatsci.2019.100578

J.K. Yoder, R.J. Griffiths, and H.Z. Yu, Deformation-Based Additive Manufacturing of 7075 Aluminum with Wrought-like Mechanical Properties, Mater. Des., 2021, 198, p 109288. https://doi.org/10.1016/j.matdes.2020.109288

D. Oropeza, D.C. Hofmann, K. Williams, S. Firdosy, P. Bordeenithikasem, M. Sokoluk, M. Liese, J. Liu, and X. Li, Welding and Additive Manufacturing with Nanoparticle-Enhanced Aluminum 7075 Wire, J. Alloys Compd., 2020, 834, p 154987. https://doi.org/10.1016/j.jallcom.2020.154987

J.H. Martin, B.D. Yahata, J.M. Hundley, J.A. Mayer, T.A. Schaedler, and T.M. Pollock, 3D Printing of High-Strength Aluminium Alloys, Nature, 2017, 549(7672), p 365–369. https://doi.org/10.1038/nature23894

H. Zhang, H. Zhu, T. Qi, Z. Hu, and X. Zeng, Selective Laser Melting of High Strength Al–Cu–Mg Alloys: Processing, Microstructure and Mechanical Properties, Mater. Sci. Eng. A, 2016, 656, p 47–54. https://doi.org/10.1016/j.msea.2015.12.101

S. Basak, S.K. Sharma, K.K. Sahu, S. Gollapudi, and J.D. Majumdar, Surface Modification of Structural Material for Nuclear Applications by Electron Beam Melting: Enhancement of Microstructural and Corrosion Properties of Inconel 617, SN Appl. Sci., 2019, 1(7), p 1–2.

T. Hauser, R.T. Reisch, P.P. Breese, B.S. Lutz, M. Pantano, Y. Nalam, K. Bela, T. Kamps, J. Volpp, and A.F.H. Kaplan, Porosity in Wire Arc Additive Manufacturing of Aluminium Alloys, Addit. Manuf., 2021, 41, p 101993. https://doi.org/10.1016/j.addma.2021.101993

S. Basak, S.K. Sharma, M. Mondal, K.K. Sahu, S. Gollapudi, J. Dutta Majumdar, and S.T. Hong, Electron Beam Surface Treatment of 316L Austenitic Stainless Steel: Improvements in Hardness, Wear, and Corrosion Resistance, Met. Mater. Int., 2020, 27, p 953.

Funding

There are no financial or non-financial interests to disclose for the authors.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors state that they have no potential conflicts of interest.

Ethical Approval

All authors have followed ethical responsibilities.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sharma, S.K., Chandra, M., Kazmi, K.H. et al. Surface Characteristics, Microstructural, and Tribological Behavior of Wire Arc Additive Manufactured Aluminum-5356 Alloy. J. of Materi Eng and Perform (2024). https://doi.org/10.1007/s11665-024-09320-x

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-024-09320-x