Abstract

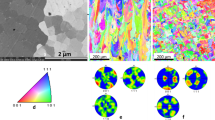

IN625 is an attractive alloy for additive manufacturing (AM) applications, but the processing conditions in AM generate considerable residual stresses, compositional gradients, and microstructural heterogeneities that degrade properties and performance. Resistance to environmentally induced cracking is of great concern for many applications within the petroleum and natural gas (PNG) industries. To evaluate the influence that AM fabrication may have on this property, AM and wrought-processed samples were given similar heat treatments and tested in tension at slow strain rates in an acidified chloride environment under both freely corroding conditions and controlled hydrogen fugacity. The results revealed that the AM solidification microstructure had a deleterious influence on the mechanical properties and significantly increased the severity of the cracking when absorbed hydrogen was present in the sample. An increase in the volume fraction of the δ-phase intensified the strength of that influence. This evaluation also demonstrated that additional thermal processing eliminated the AM solidification microstructure and the microsegregation resulting in a more homogeneous microstructure, which reduced the density and severity of the interactions between the absorbed hydrogen, interfacial precipitates (δ-phase), grain boundaries, and tri-axial stresses. It is concluded that effective post-build heat treatments can be designed that will enable AM components to perform as well as wrought components under the same environmental conditions.

Similar content being viewed by others

Notes

Certain equipment, instruments, software, or materials, commercial or non-commercial, are identified in this paper in order to specify the experimental procedure adequately. Such identification is not intended to imply recommendation or endorsement of any product or service by NIST, nor is it intended to imply that the materials or equipment identified are necessarily the best available for the purpose.

In contrast to the more common “skin and core” pattern where the laser traces the perimeter multiple times before and after the completion of each build layer, the “all-core” pattern used did not retrace the perimeter between layers thereby producing more consistent microstructures throughout the build.

References

S.S. Babu, L. Love, R. Dehoff, W. Peter, T.R. Watkins, and S. Pannala: MRS Bull., 2015, vol. 40, pp. 1154–61.

W.E. Frazier: J. Mater. Eng. Perform., 2014, vol. 23, pp. 1917–28.

D.D. Gu, W. Meiners, K. Wissenbach, and R. Poprawe: Int. Mater. Revs., 2013, vol. 57, pp. 133–64.

G.K. Dey, S. Albert, D. Srivastava, M. Sundararaman, and P. Mukhopadhyay: Mater. Sci. Engr. A, 1989, vol. 119, pp. 175–84.

G.P. Dinda, A.K. Dasgupta, and J. Mazumder: Mater. Sci. Engr. A, 2009, vol. 509, pp. 98–104.

T. DebRoy, H.L. Wei, J.S. Zuback, T. Mukherjee, J.W. Elmer, J.O. Milewski, A.M. Beese, A. Wilson-Heid, A. De, and W. Zhang: Prog. Mater. Sci., 2018, vol. 92, pp. 112–24.

W.J. Sames, F.A. List, S. Pannala, R.R. Dehoff, and S.S. Babu: Int. Mater. Revs., 2016, vol. 61, pp. 315–60.

M.J. Cieslak, T.J. Headley, A.D. Romig, and T. Kollie: Metall. Trans. A, 1988, vol. 19, pp. 2319–31.

M.R. Stoudt, E.A. Lass, D.S. Ng, M.E. Williams, F. Zhang, C.E. Campbell, G. Lindwall, and L.E. Levine: Metall. Mater. Trans. A, 2018, vol. 49, pp. 3028–37.

F. Zhang, L.E. Levine, A.J. Allen, M.R. Stoudt, G. Lindwall, E.A. Lass, M.E. Williams, Y. Idell, and C.E. Campbell: Acta Mater., 2018, vol. 152, pp. 200–14.

E.A. Lass, M.R. Stoudt, M.B. Katz, and M.E. Williams: Scripta Mater., 2018, vol. 154, pp. 83–86.

L. Suave, J. Cormier, P. Villechaise, A. Soula, Z. Hervier, D. Bertheau, and J. Laigo: Metall. Mater. Trans. A, 2014, vol. 45, pp. 2963–82.

P. Petrzak, K. Kowalski, and M. Blicharski: Acta Phys. Pol. A, 2016, vol. 130, pp. 1041–44.

M. Sundararaman, L. Kumar, G.E. Prasad, P. Mukhopadhyay, and S. Banerjee: Metall. Mater. Trans. A, 1999, vol. 30, pp. 41–52.

F. Cortial, J.M. Corrieu, and C. Vernot-Loier: Metall. Mater. Trans. A, 1995, vol. 26, pp. 1273–86.

X. Xing, X. Di, and B. Wang: J. Alloys Compd., 2014, vol. 593, pp. 110–16.

A. Sukumaran, R.K. Gupta, and V.A. Kumar: J. Mater. Eng. Perform., 2017, vol. 26, pp. 3048–57.

X. Liu, J. Fan, P. Zhang, K. Cao, Z. Wang, F. Chen, D. Liu, B. Tang, H. Kou, and J. Li: J. Alloys Compd., 2023, vol. 930, 167522.

F. Zhang, L.E. Levine, A.J. Allen, C.E. Campbell, E.A. Lass, S. Cheruvathur, M.R. Stoudt, M.E. Williams, and Y. Idell: Scripta Mater., 2017, vol. 131, pp. 98–102.

T. Keller, G. Lindwall, S. Ghosh, L. Ma, B.M. Lane, F. Zhang, U.R. Kattner, E.A. Lass, J.C. Heigel, Y. Idell, M.E. Williams, A.J. Allen, J.E. Guyer, and L.E. Levine: Acta Mater., 2017, vol. 139, pp. 244–53.

S. Ghosh, M.R. Stoudt, L.E. Levine, and J.E. Guyer: Scripta Mater., 2018, vol. 146, pp. 36–40.

E.A. Lass, M.R. Stoudt, M.E. Williams, M.B. Katz, L.E. Levine, T.Q. Phan, T.H. Gnaeupel-Herold, and D.S. Ng: Metall. Mater. Trans. A, 2017, vol. 48, pp. 5547–58.

J. Mittra, S. Banerjee, R. Tewari, and G.K. Dey: Mater. Sci. Eng. A, 2013, vol. 574, pp. 86–93.

V. Shankar, K.B.S. Rao, and S.L. Mannan: J. Nucl. Mater., 2001, vol. 288, pp. 222–32.

M. Sundararaman, P. Mukhopadhyay, and S. Banerjee: Metall. Trans. A, 1988, vol. 19, pp. 453–65.

C.U. Brown, G. Jacob, M. Stoudt, S. Moylan, J. Slotwinski, and A. Donmez: J. Mater. Eng. Perform., 2016, vol. 25, pp. 3390–97.

S. Ghosh, L. Ma, L.E. Levine, R.E. Ricker, M.R. Stoudt, J.C. Heigel, and J.E. Guyer: JOM, 2018, vol. 70, pp. 1011–16.

ASTM, (ASTM International: West Conshohocken, PA, 2013).

G. Lindwall, C.E. Campbell, E.A. Lass, F. Zhang, M.R. Stoudt, A.J. Allen, and L.E. Levine: Metall. Mater. Trans. A, 2018, vol. 14, pp. 457–67.

F. Zhang and M. R. Stoudt, Unpublished research, 2020.

G. F. VanderVoort: Metallography Principles and Practice. (ASM International, Materials Park, OH, 1999).

ASTM, (ASTM International: West Conshohocken, PA, 2021).

R.N. Iyer, H.W. Pickering, and M. Zamanzadeh: J. Electrochem. Soc., 1989, vol. 136, p. 2463.

D.A. Jones: Principles and Prevention of Corrosion, Macmillan Publishing Co, New York, 1992.

W.M. Robertson: Z. Metallkd., 1973, vol. 64, pp. 436–43.

A. Turnbull, R.G. Ballinger, I.S. Hwang, M.M. Morra, M. Psaila-Dombrowski, and R.M. Gates: Metall. Trans. A, 1992, vol. 23, pp. 3231–44.

G. Alefeld and J. Völkl: Hydrogen in Metals, Springer, New York, 1978.

Anon., (Thermo-Calc Software AB: Stockholm, Sweden, 2022).

Anon., (Themo-Calc Software AB: Stockholm, Sweden, 2021).

A.S. Wilson: Mater. Sci. Tech., 2017, vol. 33, pp. 1108–18.

J. Billingham and J. Lauridsen: Metallography, 1973, vol. 6, pp. 85–90.

J. S. Zuback and T. A. Palmer, Submitted for publication in Journal of Alloys and Compounds.

S. Floreen, G. E. Fuchs and W. J. Yang, In Superalloys 718, 625, 706 and Various Derivatives, ed. E. A. Loria (TMS: Warrendale, PA, 1994), pp 13–37.

A.A.A.P. da Silva, A. Couto, and R. Baldan: Mater. Res., 2020, vol. 23, p. 20190546.

E. Chlebus, K. Gruber, B. Kuźnicka, J. Kurzac, and T. Kurzynowski: Mater. Sci. Eng. A, 2015, vol. 639, pp. 647–55.

B. Lane, J. Heigel, R. Ricker, I. Zhirnov, V. Khromschenko, J. Weaver, T. Phan, M. Stoudt, S. Mekhontsev, and L. Levine: Integr. Mater. Manuf. Innov., 2020, vol. 9, pp. 16–30.

D.F. Martelo, R. Morana, and R. Akid: Theoret. Appl. Fract. Mech., 2021, vol. 112, 102871.

M.P. LaCoursiere, D.K. Aidun, and D.J. Morrison: J. Mater. Eng. Perform., 2017, vol. 26, pp. 2337–45.

Z. Zhang, G. Obasi, R. Morana, and M. Preuss: Acta Mater., 2016, vol. 113, pp. 272–83.

P.D. Hicks and C.J. Altstetter: Metall. Trans. A, 1992, vol. 23, pp. 237–49.

Anon.: API Standard 6ACRA: Age-Hardened Nickel-Based Alloys for Oil and Gas Drilling and Production Equipment. (American Petroleum Institute, NW Washington DC, 2019).

M.J. Benoit, M. Mazur, M.A. Easton, and M. Brandt: Int. J. Adv. Manuf. Tech., 2021, vol. 114, pp. 915–27.

K. Inaekyan, A. Kreitcberg, S. Turenne, and V. Brailovski: Mater. Sci. Eng. A, 2019, vol. 768, p. 13.

Z. Zhang, K.L. Moore, G. McMahon, R. Morana, and M. Preuss: Corros. Sci., 2019, vol. 146, pp. 58–69.

A. Kreitcberg, V. Brailovski, and S. Turenne: Mater. Sci. Eng. A, 2017, vol. 689, pp. 1–10.

G. Marchese, M. Lorusso, S. Parizia, E. Bassini, J.-W. Lee, F. Calignano, D. Manfredi, M. Terner, H.-U. Hong, D. Ugues, M. Lombardi, and S. Biamino: Mater. Sci. Eng. A, 2018, vol. 729, pp. 64–75.

Acknowledgments

The authors would like to thank the NIST Engineering Laboratory for supplying the material used in this study. The authors would also like to thank M. Ahlfors and C. Beamer of Quintus Technologies for designing and performing the HIP heat treatment used in this research, J.S. Zuback and A.D. Iams of the NIST Materials Measurement Laboratory for their help with the phase analyses, and S.A. Young, also of the NIST Materials Measurement Laboratory, for her invaluable assistance in the preparation of the tensile specimens and metallography.

Conflict of interest

The authors declare that the research presented in this document was internally funded by the National Institute of Standards and Technology and that they have no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Stoudt, M.R., Ricker, R.E. The Influence of δ-Phase on the Environmentally Assisted Cracking Resistance of an Additively Manufactured Nickel-Based Superalloy. Metall Mater Trans A 55, 335–351 (2024). https://doi.org/10.1007/s11661-023-07252-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-023-07252-0