Abstract

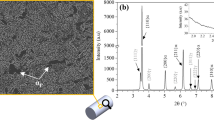

The evolution of retained austenite in a high-carbon high-silicon bearing steel is explored by high energy X-ray diffraction during continuous heating, giving insights on the control of austenite stability or decomposition during fast tempering. Retained austenite suffers two stages of slight decomposition into bainite below 400 °C, while substantial decomposition into ferrite + cementite occurs above 500 °C. Stress relief decreases retained austenite lattice anisotropy, previously introduced by the stresses caused by martensite formation during quenching. The highest rate of austenite carbon enrichment occurs at 370 °C. In comparison, the highest austenite carbon content is obtained at 466 °C, clarifying a process window for quick retained austenite stabilization with minimal phase decomposition. Austenite achieves intrinsic stacking fault energy values as high as 30 mJ m−2, avoiding the undesired transformation-induced plasticity effect for bearing application.

Similar content being viewed by others

References

S. Yan, X. Liu, W.J. Liu, T. Liang, B. Zhang, L. Liu, and Y. Zhao: Mater. Sci. Eng. A, 2017, vol. 684, pp. 261–69.

S. Liu, Z. Xiong, H. Guo, C. Shang, and R.D.K. Misra: Acta Mater., 2017, vol. 124, pp. 159–72.

B. Liu, W. Li, X. Lu, X. Jia, and X. Jin: Wear, 2019, vol. 428–429, pp. 127–36.

E. De Moor and J.G. Speer: Automotive Steels: Design, Metallurgy, Processing and Applications, Elsevier, Amsterdam, 2017, pp. 289–316.

F.G. Caballero, H.K.D.H. Bhadeshia, K.J.A. Mawella, D.G. Jones, and P. Brown: Mater. Sci. Technol., 2002, vol. 18, pp. 279–84.

F.G. Caballero and H.K.D.H. Bhadeshia: Curr. Opin. Solid State Mater. Sci., 2004, vol. 8, pp. 251–57.

J. Speer, D.K. Matlock, B.C. De Cooman, and J.G. Schroth: Acta Mater., 2003, vol. 51, pp. 2611–622.

J.G. Speer, D.V. Edmonds, F.C. Rizzo, and D.K. Matlock: Curr. Opin. Solid State Mater. Sci., 2004, vol. 8, pp. 219–37.

C. Celada-Casero, C. Kwakernaak, J. Sietsma, and M.J. Santofimia: Mater. Des., 2019, vol. 178, 107847.

S. Ayenampudi, C. Celada-Casero, J. Sietsma, and M.J. Santofimia: Materialia, 2019, vol. 8, 100492.

J. Zhang, Z. Dai, L. Zeng, X. Zuo, J. Wan, Y. Rong, N. Chen, J. Lu, and H. Chen: Acta Mater., 2021, vol. 217, 117176.

A.S. Nishikawa, G. Miyamoto, T. Furuhara, A.P. Tschiptschin, and H. Goldenstein: Acta Mater., 2019, vol. 179, pp. 1–6.

Y. Toji, H. Matsuda, M. Herbig, P.P. Choi, and D. Raabe: Acta Mater., 2014, vol. 65, pp. 215–28.

Y. Toji, G. Miyamoto, and D. Raabe: Acta Mater., 2015, vol. 86, pp. 137–47.

F. HajyAkbary, J. Sietsma, G. Miyamoto, T. Furuhara, and M.J. Santofimia: Acta Mater., 2016, vol. 104, pp. 72–83.

A.S. Nishikawa, M.J. Santofimia, J. Sietsma, and H. Goldenstein: Acta Mater., 2018, vol. 142, pp. 142–51.

S.Y.P. Allain, G. Geandier, J.C. Hell, M. Soler, F. Danoix, and M. Gouné: Scripta Mater., 2017, vol. 131, pp. 15–8.

S. Allain, J.P. Chateau, O. Bouaziz, S. Migot, and N. Guelton: Mater. Sci. Eng. A, 2004, vol. 387–389, pp. 158–62.

S. Allain, J.-P. Chateau, and O. Bouaziz: Mater. Sci. Eng. A, 2004, vol. 387–389, pp. 143–47.

B.C. De Cooman, Y. Estrin, and S.K. Kim: Acta Mater., 2018, vol. 142, pp. 283–362.

B.C. De Cooman, O. Kwon, and K.G. Chin: Mater. Sci. Technol., 2012, vol. 28, pp. 513–27.

G.G. Ribamar, J.D. Escobar, A. Kwiatkowski da Silva, N. Schell, J.A. Ávila, A.S. Nishikawa, J.P. Oliveira, and H. Goldenstein: Acta Mater., 2023, vol. 247, 118742.

V.K. Euser, D.L. Williamson, A.J. Clarke, and J.G. Speer: ISIJ Int., 2020, vol. 60, pp. 2990–3000.

M. Villa, F. Niessen, and M.A.J. Somers: Metall. Mater. Trans. A, 2018, vol. 49A, pp. 28–40.

B. Kim, E. Boucard, T. Sourmail, D. San Martín, N. Gey, and P.E.J. Rivera-Díaz-del-Castillo: Acta Mater., 2014, vol. 68, pp. 169–78.

D.H. Sherman, S.M. Cross, S. Kim, F. Grandjean, G.J. Long, and M.K. Miller: Metall. Mater. Trans. A, 2007, vol. 38A, pp. 1698–711.

J. Epp: Adv. Mater. Res., 2014, vol. 996, pp. 525–31.

S.Y.P. Allain, S. Gaudez, G. Geandier, J.-C. Hell, M. Gouné, F. Danoix, M. Soler, S. Aoued, and A. Poulon-Quintin: Mater. Sci. Eng. A, 2018, vol. 710, pp. 245–50.

J. Hidalgo, K.O. Findley, and M.J. Santofimia: Mater. Sci. Eng. A, 2017, vol. 690, pp. 337–47.

A.P. Hammersley, S.O. Svensson, M. Hanfland, A.N. Fitch, and D. Hausermann: High Press. Res., 1996, vol. 14, pp. 235–48.

A.P. Hammersley: FIT2D V12.012 Reference Manual V6.0 ESRF98HA01T, 2004.

G.A. Faria: Exploring metallic materials behavior through in situ crystallographic studies by synchrotron radiation. Universidade Estadual de Campinas, Dissertação Mestrado, 2014, p. 124. https://doi.org/10.47749/T/UNICAMP.2014.942993.

J.D. Escobar, G.A. Faria, L. Wu, J.P. Oliveira, P.R. Mei, and A.J. Ramirez: Acta Mater., 2017, vol. 138, pp. 92–9.

M.R. Daymond, M.A.M. Bourke, R.B. Von Dreele, B. Clausen, and T. Lorentzen: J. Appl. Phys., 1997, vol. 82, pp. 1554–562.

Y. Zhang, W. Chen, D.L. McDowell, Y.M. Wang, and T. Zhu: J. Mech. Phys. Solids, 2020, vol. 138, 103899.

S.M.C. van Bohemen: Scripta Mater., 2013, vol. 69, pp. 315–18.

D.J. Dyson and B. Holmes: J. Iron Steel Inst., 1970, vol. 208, pp. 469–74.

G.R. Lehnhoff, K.O. Findley, and B.C. De Cooman: Scripta Mater., 2014, vol. 92, pp. 19–22.

R. Xiong, H. Peng, H. Si, W. Zhang, and Y. Wen: Mater. Sci. Eng. A, 2014, vol. 598, pp. 376–86.

G.B. Olson and M. Cohen: Metall. Trans. A, 1976, vol. 7, pp. 1897–904.

S. Curtze, V.T. Kuokkala, A. Oikari, J. Talonen, and H. Hänninen: Acta Mater., 2011, vol. 59, pp. 1068–076.

A. Saeed-Akbari, J. Imlau, U. Prahl, and W. Bleck: Metall. Mater. Trans. A, 2009, vol. 40A, pp. 3076–090.

G.G. Ribamar, T.C. Andrade, H.C. de Miranda, and H.F.G. de Abreu: Metall. Mater. Trans. A, 2020, vol. 51A, pp. 4812–825.

L. Cheng, A. Böttger, T.H. de Keijser, and E.J. Mittemeijer: Scripta Metall. Mater., 1990, vol. 24, pp. 509–14.

E.B. Fonseca, J.D. Escobar, A.H.G. Gabriel, G.G. Ribamar, T. Boll, and É.S.N. Lopes: Addit. Manuf., 2022, vol. 55, 102812.

S. Harjo, J. Abe, K. Aizawa, W. Gong, and T. Iwahashi: Proceedings of the 12th Asia Pacific Physics Conference (APPC12), 2014, March, Journal of the Physical Society of Japan. http://journals.jps.jp/doi/10.7566/JPSCP.1.014017.

C. Suryanarayana and M.G. Norton: X-Ray Diffraction, Springer, Boston, 1998.

X.C. Xiong, B. Chen, M.X. Huang, J.F. Wang, and L. Wang: Scripta Mater., 2013, vol. 68, pp. 321–24.

L.C. Chang and H.K.D.H. Bhadeshia: Mater. Sci. Technol., 1995, vol. 11, pp. 874–82.

Acknowledgments

This study was financed in part by the Coordenação de Aperfeiçoamento de Pessoal de Nível Superior—Brasil (CAPES)—Finance Code 001 and FAPESP, Grant 2019/00691-0. This work was supported by ICC-IMR, Tohoku University. A. Avila is a Serra Hunter Fellow and a CNPq Fellow. Hélio Goldenstein and Giovani G. Ribamar acknowledges partial funding from a CNPq Grant. JPO acknowledges funding by national funds from FCT—Fundação para a Ciência e a Tecnologia, IP, in the scope of the Projects LA/P/0037/2020, UIDP/50025/2020 and UIDB/50025/2020 of the Associate Laboratory Institute of Nanostructures, Nanomodelling and Nanofabrication—i3N. The authors acknowledge DESY (Hamburg, Germany), a member of the Helmholtz Association HGF, for providing experimental facilities. Beamtime was allocated for proposal I-20210899 EC. The research leading to this result has been supported by the Project CALIPSOplus under Grant Agreement 730872 from the EU Framework Programme for Research and Innovation HORIZON 2020.

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

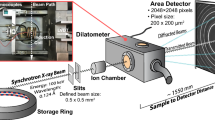

Ribamar, G.G., Miyamoto, G., Furuhara, T. et al. On the Evolution of Austenite During Tempering in High-Carbon High-Silicon Bearing Steel by High Energy X-Ray Diffraction. Metall Mater Trans A 55, 93–100 (2024). https://doi.org/10.1007/s11661-023-07229-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-023-07229-z