Abstract

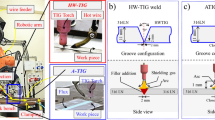

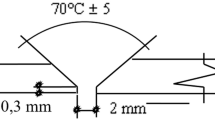

In the present investigation, creep deformation and rupture behavior of type 316LN stainless steel weld joints fabricated from hotwire tungsten inert gas (HW-TIG), activated-TIG (A-TIG), and hybrid laser metal inert gas (HLM) welding processes were studied. The creep testing was carried out at 923 K under various stress levels. The weld joints have undergone a higher rate of deformation and exhibited lower creep rupture life as compared to that of the base metal. The welding process significantly influenced the delta (δ)-ferrite content in the weld metal of stainless steel weld joints [A-TIG (1.7 ferrite number (FN)], HLM (1.3 FN), and HW-TIG (3.5 FN), its morphology and also the creep cavity density during creep deformation. The HW-TIG weld joint possessed significantly lower creep rupture life than that of the A-TIG and HLM weld joints. The HLM joint has exhibited a better creep rupture life than the A-TIG and HW-TIG weld joints. The microstructural constituents, i.e., δ-ferrite content, columnar and equiaxed dendrites, and sigma (σ)-phase formation during creep, have significantly influenced the creep deformation and rupture strength of the joints. The orientation of the columnar structure, which is parallel to stress direction and lower δ-ferrite content in the A-TIG and HLM joints, has resulted in lower creep cavitation and higher creep rupture strength as compared to that of the HW-TIG weld joint. As the 316LN stainless steel weld joint processed by the HLM welding process exhibited the best creep rupture life, the HLM welding process is recommended for the welding of 316LN stainless steel.

Similar content being viewed by others

References

A.K. Bhaduri, K. Laha, V. Ganesan, T. Sakthivel, M. Nandagopal, G.V.P. Reddy, J.G. Kumar, V.D. Vijayanand, S.P. Selvi, G. Srinivasan, C.R. Das, A. Nagesha, S. Ravi, P. Parameswaran, R. Sandhya, and S.K. Albert: Int. J. Press. Vessel Pip., 2016, vol. 139–140, pp. 123–36.

B. Arivazhagan and M. Vasudevan: J. Manuf. Process., 2015, vol. 18, pp. 55–59.

M. Vasudevan: PhD Thesis, Indian Institute of Technology, Chennai, India.

T. Sakthivel, M. Vasudevan, K. Laha, P. Parameswaran, K.S. Chandravathi, M.D. Mathew, and A.K. Bhaduri: Procedia Eng., 2013, vol. 55, pp. 408–13.

R.G. Berggren, N.C. Cole, G.M. Goodwin, J.O. Stiegler, G.M. Slaughter, R.J. Gray, and R.T. King: Weld. J., 1978, vol. 57, pp. 167s–174s.

R.G. Thomas: Weld. J., 1978, vol. 57, pp. 1–6.

G. Sasikala, S.L. Mannan, M.D. Mathew, and K.B. Rao: Metall. Mater. Trans. A, 2000, vol. 31A, pp. 1175–85.

G. Sasikala, S.K. Ray, and S.L. Mannan: Acta Mater., 2004, vol. 52, pp. 5677–86.

K. Hori, K. Kusano, and T. Myoga: Weld. Int., 2004, vol. 18, pp. 456–68.

M. Vasudevan: J. Mater. Eng. Perform., 2017, vol. 26, pp. 1325–36.

T. Sakthivel, M. Vasudevan, K. Laha, P. Parameswaran, K.S. Chandravathi, M.D. Mathew, and A.K. Bhaduri: Mater. Sci. Eng. A, 2011, vol. 528, pp. 6971–80.

C. Fang, J. Xin, W. Dai, J. Wei, J. Wu, and Y. Song: J. Laser Appl., 2020, vol. 32, p. 012009.

X.N. Wang, S.H. Zhang, J. Zhou, M. Zhang, C.J. Chen, and R.D.K. Misra: Opt. Lasers Eng., 2017, vol. 91, pp. 86–96.

J. Yan, M. Gao, and X. Zeng: Opt. Lasers Eng., 2010, vol. 48, pp. 512–17.

P.L. Moore, D.S. Howse, and E.R. Wallach: Sci. Technol. Weld. Join., 2004, vol. 9, pp. 314–22.

A.R. Pavan, N. Chandrasekar, B. Arivazhagan, S. Kumar, and M. Vasudevan: CIRP J. Manuf. Sci. Technol., 2021, vol. 35, pp. 675–90.

A.R. Pavan, B. Arivazhagan, M. Vasudevan, and S. Govind Kumar: CIRP J. Manuf. Sci. Technol., 2022, vol. 39, pp. 294–307.

A.R. Pavan, B. Arivazhagan, G.K. Sharma, S.A. Kumar, S. Mahadevan, and M. Vasudevan: J. Mater. Eng. Perform., 2022, https://doi.org/10.1007/s11665-022-06654-2.

S. Kou: Welding Metallurgy, Wiley, Hoboken, 2003.

M. Ragavendran and M. Vasudevan: Mater. Manuf. Process., 2020, vol. 35, pp. 922–34.

M.D. Mathew, S. Latha, and K.B.S. Rao: Mater. Sci. Eng. A, 2007, vol. 456, pp. 28–34.

V. Shankar, T.P.S. Gill, S.L. Mannan, and S. Sundarlsan: Sadhana Acad. Proc. Eng. Sci., 2003, vol. 28, pp. 359–82.

A. Elmesalamy, J.A. Francis, and L. Li: Int. J. Press. Vessel Pip., 2014, vol. 113, pp. 49–59.

D.R. Bajic, M.M. Savitsky, G.M. Melnichuk, and A.F. Lupan: Pat. Weld. J. C/C Avtom. SVARKA, 2002, vol. 9, pp. 30–34.

K.R. Gadelrab, G. Li, M. Chiesa, and T. Souier: J. Mater. Res., 2012, vol. 27, pp. 1573–79.

M. Ragavendran, M. Vasudevan, and N. Hussain: J. Mater. Eng. Perform., 2022, https://doi.org/10.1007/s11665-021-06534-1.

S.L. Mannan and M.D. Mathew: Bull. Mater. Sci., 1996, vol. 19, pp. 985–1007.

M.D. Mathew, K. Laha, and V. Ganesan: Mater. Sci. Eng. A, 2012, vol. 535, pp. 76–83.

RCC-MR, Design and Construction Rules for Mechanical Components for FBR Nuclear Islands, Section I–Subsection Z, Appendix 3, 1985.

B.A. Senior: J. Mater. Sci., 1990, vol. 25, pp. 45–53.

J.J. Smith and R.A. Farrar: Int. Mater. Rev., 1993, vol. 38, pp. 25–51.

B. Weiss and R. Stickler: Metall. Mater. Trans. B, 1972, vol. 3B, pp. 851–66.

J.K. Lai and A. Wickens: Acta Metall., 1979, vol. 27, pp. 217–30.

C.-C. Hsieh and W. Wu: ISRN Metall., 2012, vol. 2012, pp. 1–16.

A.F. Padilha, D.M. Escriba, E. Materna-Morris, M. Rieth, and M. Klimenkov: J. Nucl. Mater., 2007, vol. 362, pp. 132–38.

T. Sakthivel, M. Vasudevan, K. Laha, P. Parameswaran, K.S. Chandravathi, M.D. Mathew, and A.K. Bhaduri: J. Nucl. Mater., 2011, vol. 413, pp. 36–40.

M. Ragavendran, J.G. Kumar, and M. Vasudevan: Mater. Sci. Eng. A, 2022, vol. 832, p. 142445.

Acknowledgments

The authors acknowledge Dr. Arup Dasgupta, Head, Physical Metallurgy Division, Indira Gandhi Centre for Atomic Research (IGCAR), India, for providing the EBSD Facility. Dr. S. Mahadevan and Shri. S. Arun Kumar are earnestly acknowledged for residual stress measurements using the X-ray diffraction technique and fruitful discussions during this work.

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Pavan, A.R., Sakthivel, T., Arivazhagan, B. et al. Microstructures and Creep Properties of Type 316LN Stainless Steel Weld Joints. Metall Mater Trans A 54, 4868–4890 (2023). https://doi.org/10.1007/s11661-023-07208-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-023-07208-4