Abstract

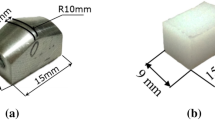

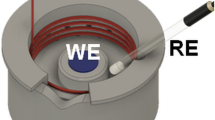

The role of bovine calf serum (BCS) related to the functional performance of synovial fluid on the tribological behavior of borides grown on cobalt–28chromium–6molybdenum (Co–28Cr–6Mo) alloy used in orthopedic prostheses is not known yet. Here, the borides were grown on Co–28Cr–6Mo surface for 5 and 7 hours at 975 °C using 90 wt pct boron carbide (B4C) and 10 wt pct sodium tetrafluoroborate (NaBF4) powders. The borides were characterized by X-ray diffractometer (XRD), nanoindentation, scanning electron microscope (SEM) and energy dispersive spectroscope (EDS). The tribological performance of the borides was evaluated using a ball-on-disk type tribometer in dry-sliding condition and different biological fluids (phosphate buffered saline (PBS) and BCS). The thickness, nanohardness and elastic modulus values of the borides composed of a bilayer Co2B and CoB phases were observed to be 33.3 to 40 µm, 22.34 to 24.30 GPa and 224.46 to 229.27 GPa, respectively. Following the boriding process, the volume loss of Co–28Cr–6Mo decreased from 0.275 to 0.122-0.142 mm3 owing to the high hardness and elastic modulus of the formed boride layers. The lubricating effect of PBS and BCS fluids has a great influence on the friction and wear performance of the boride layers. With the introduction of PBS lubricant into the tribosystem, the worn volume and COF of the borides significantly decreased from 0.122-0.142 to 0.014 mm3 and from 0.68-0.75 to 0.21-0.25, respectively. Plasma proteins present in BCS lubricant managed to reduce these values even further and showed a COF of 0.09 and the worn volume of 0.002 to 0.003 mm3. SEM and EDS analyses showed that the main failure mechanism of the borides was changed from oxidation-assisted delamination in dry-sliding condition to micro-scratches in BCS lubricant. The superior wear and friction performance of the borides (grown on Co–28Cr–6Mo) in BCS lubricant suggests its potential usage for orthopedic implant products although further in-vitro and in-vivo studies are needed to verify this potential.

Graphical Abstract

Similar content being viewed by others

References

R. Saravanan, R. Hamidon, N. Murad, and Z. Zailani: Intell. Manuf. Mechatron., 2021, pp. 413–24.

L.C. Julian and A.I. Muñoz: Tribol. Int., 2011, vol. 44, pp. 318–29.

A. I. Muñoz and S. Mischler, J. Mater. Sci., 2011, vol. 22, pp. 437-50.

M. Taufiqurrakhman, M.G. Bryant, and A. Neville: Biotribology, 2019, vol. 19, 100104.

R. Namus and W. Rainforth: Tribol. Int., 2020, vol. 150, 106364.

J.R. Davis: ASM International, 2000.

R. Morón, A. Delgado-Brito, and I. Campos-Silva: Mater. Lett., 2022, vol. 309, 131352.

D. Mu and B.-L. Shen: Int. J. Refract. Metal Hard Mater., 2010, vol. 28, pp. 424–28.

A. Cigada, G. Cotogno, and R. Chiesa: J. Appl. Biomater. Biomech., 2011, vol. 9, pp. 2–10.

K. Shukla, A.A. Sugumaran, I. Khan, A.P. Ehiasarian, and P.E. Hovsepian: J. Mech. Behav. Biomed. Mater., 2020, vol. 111, 104004.

J. Döring, M. Crackau, C. Nestler, F. Welzel, J. Bertrand, and C.H. Lohmann: J. Mech. Behav. Biomed. Mater., 2019, vol. 97, pp. 212–21.

A.K. Aslan, E. Bahce, and M.S. Güler: Mater. Sci., 2021, vol. 27, pp. 416–24.

J. Corona-Gomez and Q. Yang: Materialia, 2022, vol. 24, 101518.

V. Huynh, N.K. Ngo, and T.D. Golden: Int. J. Biomater., 2019.

J. Corona-Gomez, T. Jack, R. Feng, and Q. Yang: Mater. Charact., 2021, vol. 182, 111516.

C.-E. Tsai, J. Hung, Y. Hu, D.-Y. Wang, R.M. Pilliar, and R. Wang: J. Mech. Behav. Biomed. Mater., 2021, vol. 114, 104233.

A. Mazzonello, J. Buhagiar, R. Chetcuti, P.A. Dearnley, A. Valsesia, P. Colpo, and B. Mallia: Surf. Coat. Technol. 2022, p. 128341.

A. Delgado-Brito, I. Mejía-Caballero, M. Palomar-Pardavé, J. Martínez-Trinidad, and I. Campos-Silva: Surf. Coat. Technol., 2021, vol. 421, 127462.

M. Doñu-Ruiz, N. López-Perrusquia, A. Renteria-Salcedo, M. Flores-Martinez, E. R. Anda, S. Muhl, C. Hernández-Navarro, and E. García: Surf. Coat. Technol., 2021, vol. 425, p. 127698.

C.D. Resendiz-Calderon, L.I. Farfan-Cabrera, G.A. Rodríguez-Castro, and E.A. Gallardo-Hernandez: J. Mater. Eng. Perform., 2021, vol. 30, pp. 3955–67.

M. Öge, Y. Küçük, T. Özdemir Öge, A. Günen, Y. Kanca, and M.S. Gök: Tribol. Int., 2023, p. 108697.

A. Günen, E. Kanca, M. Demir, Y. Er, G. Sağlam, and M.S. Gök: Tribol. Trans., 2017, vol. 60, pp. 267–75.

S. Timur, G. Kartal, O.L. Eryilmaz, and A. Erdemir: Argonne, IL, 2015.

M. Kulka: Springer, 2019.

M.S. Karakaş, A. Günen, C. Çarboğa, Y. Karaca, M. Demir, Y. Altınay, and A. Erdoğan: J. Alloys Compd., 2021, vol. 886, 161222.

R. Ribeiro, S. Ingole, M. Usta, C. Bindal, A. Ucisik, and H. Liang: Wear, 2007, vol. 262, pp. 1380–86.

G. Ciofani, S. Danti, S. Nitti, B. Mazzolai, V. Mattoli, and M. Giorgi: Int. J. Pharm., 2013, vol. 444, pp. 85–8.

G. Ciofani, S. Danti, G.G. Genchi, D. D’Alessandro, J.-L. Pellequer, M. Odorico, V. Mattoli, and M. Giorgi: Int. J. Nanomed., 2012, vol. 7, pp. 19–24.

O. Gokcekaya, C. Ergun, T.J. Webster, and T. Nakano: Ceram. Int., 2023, vol. 49, pp. 7506–14.

I. Campos-Silva, D. Bravo-Bárcenas, H. Cimenoglu, U. Figueroa-López, M. Flores-Jiménez, and O. Meydanoglu: Surf. Coat. Technol., 2014, vol. 260, pp. 362–68.

G. Rosas-Becerra, I. Mejía-Caballero, J. Martínez-Trinidad, M. Palomar-Pardavé, M. Romero-Romo, R. Pérez-Pasten-Borja, and I. Campos-Silva: J. Mater. Eng. Perform., 2017, vol. 26, pp. 704–14.

C. Cuao-Moreu, E. Hernández-Sanchéz, M. Alvarez-Vera, E. Garcia-Sanchez, A. Perez-Unzueta, and M. Hernandez-Rodriguez: Wear, 2019, vol. 426, pp. 204–11.

A. Delgado-Brito, A. Contla-Pacheco, V. Castrejón-Sánchez, D. López-Suero, J. Oseguera-Peña, and I. Campos-Silva: J. Mater. Eng. Perform., 2020, vol. 29, pp. 109–25.

I. Campos-Silva, A. Delgado-Brito, J. Oseguera-Peña, J. Martínez-Trinidad, O. Kahvecioglu-Feridun, R.P. Pasten-Borja, and D. López-Suero: Surf. Coat. Technol., 2019, vol. 375, pp. 810–23.

K.M. Oates, W.E. Krause, R.L. Jones, and R.H. Colby: J. R. Soc. Interface, 2006, vol. 3, pp. 167–74.

T. Kitano, G.A. Ateshian, V.C. Mow, Y. Kadoya, and Y. Yamano: J. Biomech., 2001, vol. 34, pp. 1031–37.

M. Wimmer, C. Sprecher, R. Hauert, G. Täger, and A. Fischer: Wear, 2003, vol. 255, pp. 1007–14.

A.-M. Trunfio-Sfarghiu, Y. Berthier, M.-H. Meurisse, and J.-P. Rieu: Tribol. Int., 2007, vol. 40, pp. 1500–15.

Y. Kanca, P. Milner, D. Dini, and A.A. Amis: J. Mech. Behav. Biomed. Mater., 2018, vol. 78, pp. 36–45.

Y. Kanca, P. Milner, D. Dini, and A.A. Amis: J. Mech. Behav. Biomed. Mater., 2018, vol. 82, pp. 394–402.

H. Stevenson, M. Parkes, L. Austin, M. Jaggard, P. Akhbari, U. Vaghela, H. Williams, C. Gupte, and P. Cann: Biotribology, 2018, vol. 14, pp. 1–0.

B. Kurt, L. Özdoğan, B. Güney, Ö.S. Bölükbaşı, and A. Günen: Surf. Coat. Technol., 2020, vol. 385, 125332.

A. Günen, N. Makuch, Y. Altınay, C. Çarboğa, S. Dal, and Y. Karaca: Ceram. Int., 2022, vol. 48, pp. 36410–24.

W.C. Oliver and G.M. Pharr: J. Mater. Res., 2004, vol. 19, pp. 3–20.

J.H. Dumbleton: Elsevier, 1981.

E.L. Bortel, B. Charbonnier, and R. Heuberger: Lubricants, 2015, vol. 3, pp. 664–86.

B.T. Graham, A.C. Moore, D.L. Burris, and C. Price: Osteoarthr. Cartil., 2017, vol. 25, pp. 2100–07.

J. Xu, C. Zhang, and J. Luo: ACS Applied Polymer Materials, 2022, vol. 4, pp. 7487–497.

M.E. Kupratis, A.E. Gure, K.F. Ortved, D.L. Burris, and C. Price: Biotribology, 2021, vol. 25, 100159.

Y. Kanca, M.C. Uçgun, and A. Günen: Metall. Mater. Trans. A., 2023, vol. 54A, pp. 671–87.

C. Reséndiz-Calderón, L. Farfan-Cabrera, J. Oseguera-Peña, and G. Rodríguez-Castro: Mater. Lett., 2020, vol. 279, 128500.

A. Meneses-Amador, D. Sandoval-Juárez, G. Rodríguez-Castro, D. Fernández-Valdés, I. Campos-Silva, R. Vega-Morón, and J. Arciniega-Martínez: Surf. Coat. Technol., 2018, vol. 353, pp. 346–54.

D. Mu, B.-L. Shen, and X. Zhao: Mater. Des., 2010, vol. 31, pp. 3933–936.

A. Günen, M. Keddam, S. Alkan, A. Erdoğan, and M. Çetin: Mater. Charact., 2022, vol. 186, 111778.

A. Delgado-Brito, D. López-Suero, A. Ruiz-Ríos, R. García-León, J. Martínez-Trinidad, J. Oseguera-Peña, and I. Campos-Silva: Ceram. Int., 2019, vol. 45, pp. 7767–77.

W.D. Callister and D.G. Rethwisch, Wiley, New York, 2018.

R. Morón, G. Rodríguez-Castro, G. Maldonado, A. Salazar-Gaona, D. Bravo-Bárcenas, I. Campos-Silva, and A. Palacios-Méndez: J. Tribol., 2019, vol. 141(8), p. 081602.

Y. Uzun, H. Kovacı, A.F. Yetim, and A. Çelik: Ind. Lubr. Tribol., 2018, vol. 71(3), pp. 348–56.

M.S. Karakaş, A. Günen, E. Kanca, and E. Yilmaz: Arch. Metall. Mater., 2018, vol. 63, pp. 159–65.

I. Campos-Silva, D. Bravo-Bárcenas, A. Meneses-Amador, M. Ortiz-Dominguez, H. Cimenoglu, U. Figueroa-López, and J. Andraca-Adame: Surf. Coat. Technol., 2013, vol. 237, pp. 402–14.

V. Martinez-Nogues, J. Nesbitt, R. Wood, and R. Cook: Tribol. Int., 2016, vol. 93, pp. 563–72.

R. Ahmed, H. de Villiers Lovelock, N.H. Faisal, and S. Davies: Tribol. Int., 2014, vol. 80, pp. 98-114.

P. Dearnley and T. Bell: Surf. Eng., 1985, vol. 1, pp. 203–17.

R. Kouba, M. Keddam, and M. Kulka: Met. Sci. Heat Treat., 2021, vol. 63, pp. 106–13.

S.C. Jambagi and V.R. Malik: JOM, 2021, vol. 73(12), pp. 4349–64.

P.J. Blau, CRC Press, 2008.

F. Guo, M. Hua, J.K. Ho, and G. Dong: Tribol. Trans., 2016, vol. 59, pp. 1070–080.

I. Campos-Silva, R.C. Vega-Morón, C.D. Reséndiz-Calderón, D. Bravo-Bárcenas, O.L. Eryilmaz, O. Kahvecioglu-Feridun, and G. Rodríguez-Castro: J. Mater. Eng. Perform., 2019, vol. 28, pp. 2399–410.

M.S. Karakaş: Surf. Coat. Technol., 2020, vol. 394, 125884.

M.V. Çakir: Prot. Met. Phys. Chem. Surf., 2022, vol. 58, pp. 562–73.

C. Çarboğa: Emerg. Mater. Res., 2021, vol. 11, pp. 33–40.

M. Heuberger, M. Widmer, E. Zobeley, R. Glockshuber, and N. Spencer: Biomaterials, 2005, vol. 26, pp. 1165–73.

A. Mavraki and P. Cann: Tribol. Int., 2011, vol. 44, pp. 550–56.

Y. Kanca: Surf. Coat. Technol., 2022, vol. 449, 128973.

R. Yazdi, H. Ghasemi, M. Abedini, and M. Monshi: Appl. Surf. Sci., 2020, vol. 518, 146048.

R. Dwyer-Joyce: Wear, 1999, vol. 233, pp. 692–701.

A. Kovalchenko, O. Ajayi, A. Erdemir, and G. Fenske: Wear, 2011, vol. 271, pp. 1719–25.

Acknowledgments

The financial support from the Scientific Projects Coordination Unit of Hitit University under the project number MUH19001.20.001 is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kanca, Y., Gokcekaya, O. & Günen, A. Sliding Wear and Friction Performance of Pack-Borided Co–28Cr–6Mo Alloy in Physiological Lubricants. Metall Mater Trans A 54, 4634–4649 (2023). https://doi.org/10.1007/s11661-023-07163-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-023-07163-0