Abstract

This study aims to investigate the effect of the presence of a simulated corrosive body fluid (Hank’s solution) on the micro-abrasion and corrosion resistance of two borided biomedical alloys (AISI 316L stainless steel and ASTM F1537 CoCrMo alloy) when in sliding contact with a ceramic countersurface. The materials were subjected to a powder-pack boriding treatment. The modified surfaces were characterized mechanically and physico-chemically. The changes of wear resistance of both borided alloys were determined by means of micro-abrasion tests using a slurry made of the corrosive solution with F-1200 SiC abrasive particles. 25-mm-diameter dielectric glass balls were used as countersurface in the wear tests with the twofold purpose of replicating a ceramic-on-ceramic biomedical contact and avoiding the effect of galvanic corrosion with the metallic samples to be tested. The tests were run in triplicated at 0.1, 0.2 and 0.5N of applied load at constant sliding distance and speed. The wear volumes and wear scar examination were carried out by optical profilometry and microscopy. On the other hand, the corrosion resistance of the materials (before and after boriding treatment) was characterized by potentiodynamic polarization measurements in a closed three-electrode cell using the corrosive fluid. According to the results found, the hardness of the alloys increased significantly between 300 and 400% by boriding. However, the micro-abrasion/corrosion situation was detrimental for both alloys under sliding with the ceramic countersurface in the presence of Hank’s solution, which is opposite to that reported in literature for other abrasion–corrosion conditions investigated.

Similar content being viewed by others

References

A. Cigada, G. Cotogno and R. Chiesa, The Ceramic-on-Metal Coupling in Total Hip Replacements for Young Patients: A Review Study, J. Appl. Biomater. Biomech., 2011, 9(1), p 2-10. https://doi.org/10.5301/JABB.2011.7730

S. Affatato, M. Spinelli, M. Zavalloni, F. Traina, S. Carmignato and A. Toni, Ceramic-On-Metal for Total Hip Replacement: Mixing and Matching Can Lead to High Wear, Artif Organs, 2010, 34(4), p 319-323. https://doi.org/10.1111/j.1525-1594.2009.00854.x

Y. Núñez, M. Mafra, R.E. Morales, P.C. Borges and G. Pintaude, The Effect of Plasma Nitriding on the Synergism Between Wear and Corrosion of SAF 2205 Duplex Stainless Steel, Ind. Lubr. Tribol., 2020, 72(9), p 1117–1122. https://doi.org/10.1108/ilt-08-2019-0302

Z. Wang, W. Huang, Y. Li, H. He, Y. Zhou and Z. Zheng, Tribocorrosion Behaviour of a Biomedical Ti-25Nb-3Mo-3Zr-2Sn Alloy in Ringer’s Solution, Mater. Sci. Eng. C., 2017, 76, p 1094–1102. https://doi.org/10.1016/j.msec.2017.03.206

Z. Wang, Y. Li, W. Huang, X. Chen and H. He, Micro-abrasion–Corrosion Behaviour of a Biomedical Ti–25Nb–3Mo–3Zr–2Sn Alloy in Simulated Physiological Fluid, J. Mech. Behav. Biomed. Mater., 2016, 63, p 361–374. https://doi.org/10.1016/j.jmbbm.2016.07.010

H. Maleki-Ghaleh, J. Khalil-Allafi, E. Aghaie and M.H. Siadati, Effect of TiO2-Ti and TiO2-TiN Composite Coatings on Corrosion Behavior of NiTi Alloy, Surf. Interface Anal., 2014, 47(1), p 99–104. https://doi.org/10.1002/sia.5679

M. Mahmoudi, H. Maleki-Ghaleh and M. Kavanlouei, Electrophoretic Deposition and Reaction-Bond Sintering of Al2O3/Ti Composite Coating: Evaluation of Microstructure, Phase and Wear Resistance, Bull. Mater. Sci., 2015, 38(2), p 351–356. https://doi.org/10.1007/s12034-015-0882-3

M. Mahmoudi, H. Maleki-Ghaleh, M. Kavanlouei and E. Aghaie, Effect of Al2O3-Ti Composite Coating on Corrosion Behavior of TiAl6V4alloy, Mater. Corros., 2014, 66(5), p 479–485. https://doi.org/10.1002/maco.201307486

H. Maleki-Ghaleh and J. Khalil-Allafi, Effect of Hydroxyapatite-Titanium-MWCNTs Composite Coating Fabricated by Electrophoretic Deposition on Corrosion and Cellular Behavior of NiTi Alloy, Mater. Corros., 2019, 70(11), p 2128–2138. https://doi.org/10.1002/maco.201910940

I. Campos-Silva, R.C. Vega-Moron, C.D. Reséndiz-Calderón, D. Bravo-Barcenas, O.L. Eryilmaz, O. Kahvecioglu-Feridum and G. Rodríguez-Castro, Dry Sliding Wear Resistance of Cobalt Boride Coatings Formed on ASTM F1537, Alloy. J. Mater. Eng. Perform., 2018, 28, p 2399–2410.

D. Mu, B. Shen and X. Zhao, Effects of Boronizing on Mechanical and Dry-Sliding Wear Properties of CoCrMo Alloy, Mater. Des., 2010, 31, p 3933–3936.

C.A. Cuao-Moreu, E. Hernández-Sanchéz, M. Alvarez-Vera, E.O. Garcia-Sanchez, A. Perez-Unzueta and M.A.L. Hernandez-Rodriguez, Tribological Behavior of Borided Surface on CoCrMo Cast Alloy, Wear, 2019, 426–427(Part A), p 204–211.

Y. Kayali, A. Büyüksa and Y. Yalçin, Corrosion and Wear Behaviors of Boronized AISI 316L Stainless Steel, Met. Mater. Int., 2013, 19, p 1053–1061.

I. Campos-Silva, M. Palomar-Pardavé, R. Pérez Pastén-Borja, O. Kahvecioglu Feridun, D. Bravo-Bárcenas, C. López-García and R. Reyes-Helguera, Tribocorrosion and Cytotoxicity of FeB-Fe2B Layers on AISI 316 L Steel, Surf. Coat. Tech., 2018, 349, p 986–997.

I. Campos-Silva, A.M. Delgado-Brito, J. Oseguera-Pena, J. Martinez-Trinidad, O. Kahvecioglu-Feridun, R. Perez Pasten-Borja and D. Lopez-Suero, Tribocorrosion Resistance of Borided ASTM F1537 Alloy, Surf. Coat. Tech., 2019, 375, p 810–823.

L. Yang and E. Zhang, Biocorrosion Behaviour of Magnesium Alloy in Different Simulated Fluids for Medical Application, Mater. Sci. Eng. C, 2009, 29, p 1691–1696.

S. Kaur, K. Ghadirinejad and R. Oskouei, An Overview on the Tribological Performance of Titanium Alloys with Surface Modifications for Biomedical Applications, Lubricants, 2019, 7, p 65.

M.P. Gispert, A.P. Serro, R. Colaço, E. Pires and B. Saramago, The Effect of Roughness on the Tribological Behavior of the Prosthetic Pair UHMWPE/TiN-Coated Stainless Steel, J. Biomed. Mater. Res. B Appl. Biomater., 2008, 84(1), p 98–107. https://doi.org/10.1002/jbm.b.30849

A. Choubey, B. Basu and R. Balasubramaniam, Tribological Behaviour of Ti-Based Alloys in Simulated Body Fluid Solution at Fretting Contacts, Mater. Sci. Eng. A, 2004, 379, p 234–239.

M.P. Gispert, A.P. Serro, R. Colaço and B. Saramago, Friction and Wear Mechanisms in Hip Prosthesis: Comparison of Joint Materials Behaviour in Several Lubricants, Wear, 2006, 260(1–2), p 149–158.

I. Catelas, J.D. Bobyn, J.B. Medley, J.J. Krygier, D.J. Zukor and O.L. Huk, Size, Shape, and Composition of Wear Particles from Metal-Metal Hip Simulator Testing: Effects of Alloy and Number of Loading Cycles, J. Biomed. Mater. Res. A, 2003, 67(1), p 312–327.

H.L. Anissian, A. Stark, V. Good, H. Dahlstrand and I.C. Clarke, The Wear Pattern in Metal-on- Metal Hip Prostheses, J. Biomed. Mater. Res. A, 2001, 58(6), p 673–678.

R. Trezona and I.M. Hutchings, Three-Body Abrasive Wear Testing of Soft Materials, Wear, 1999, 209–221, p 233–235.

A.P. Krelling, F. Teixeira, C.E. da Costa, E.A.S. Almeida, B. Zappelino and J.C.G. Milan, Microabrasive Wear Behavior of Borided Steel Abraded by SiO2 Particles, J. Mater. Res. Technol., 2019, 8(1), p 766–776. https://doi.org/10.1016/j.jmrt.2018.06.004

A.P. Krelling, C.E. da Costa, J.C.G. Milan and E.A.S. Almeida, Micro-abrasive Wear Mechanisms of Borided AISI 1020 Steel, Tribol. Int., 2017, 111, p 234–242. https://doi.org/10.1016/j.triboint.2017.03.017

G.A. Rodríguez-Castro, C.D. Reséndiz-Calderón, L.F. Jímenez-Tinoco, A. Meneses-Amador and E.A. Gallardo-Hernandez, Micro-abrasive Wear Resistance of CoB/Co2B Coatings Formed in CoCrMo Alloy, Surf. Coat. Technol., 2015, 284, p 258–263.

C.D. Resendiz-Calderon, G.A. Rodríguez-Castro, A. Meneses-Amador, I.E. Campos-Silva, J. Andraca-Adame, M.E. Palomar-Pardavé and E.A. Gallardo-Hernández, Micro-abrasion Wear Resistance of Borided 316L Stainless Steel and AISI 1018 Steel, J. Mater. Eng. Perform., 2017, 26, p 5599–5609.

K. Sadiq, M.A. Sim, R.A. Black and M.M. Stack, Mapping the Micro-Abrasion Mechanisms of CoCrMo: Some Thoughts on Varying Ceramic Counterface Diameter on Transition Boundaries In Vitro, Lubricants, 2020, 8, p 71.

R. Trezona, D. Allsopp and I. Hutchings, Transitions Between Two-Body and Three-Body Abrasive Wear: Influence of Test Conditions in the Microscale Abrasive Wear Test, Wear, 1999, 225–229, p 205–214. https://doi.org/10.1016/s0043-1648(98)00358-5

R. Trezona and I. Hutchings, Three-Body Abrasive Wear Testing of Soft Materials, Wear, 1999, 233–235, p 209–221. https://doi.org/10.1016/s0043-1648(99)00183-0

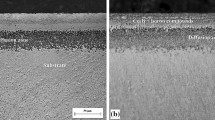

I. Campos-Silva, D. Bravo-Bárcenas, A. Meneses-Amador, M. Ortiz-Dominguez, H. Cimenoglu, U. Figueroa-López and J. Andraca-Adame, Growth Kinetics and Mechanical Properties of Boride Layers Formed at the Surface of the ASTM F-75 Biomedical Alloy, Surf. Coat. Technol., 2013, 237, p 402–414.

I. Campos-Silva, M. Ortiz-Domínguez, O. Bravo-Bárcenas, M.A. Doñu-Ruiz, D. Bravo-Bárcenas, C. Tapia-Quintero and M.Y. Jiménez-Reyes, Formation and Kinetics of FeB/Fe2B Layers and Diffusion Zone at the Surface of AISI 316, Borided Steels, 2010, 205, p 403–412.

R. Câmara Cozza and C. Geraldo Schön, Evidence of Superposition between Grooving Abrasion and Rolling Abrasion, Tribol. Trans., 2015, 58(5), p 875–881. https://doi.org/10.1080/10402004.2015.1024907

C.D. Reséndiz-Calderón, L.I. Farfan-Cabrera, J.E. Oseguera-Peña and G.A., Rodríguez-Castro, , Wear and Friction of Boride Layer in CoCrMo Alloy Under Different Micro-abrasion Modes (Rolling and Grooving Abrasion), Mater. Lett., 2020, 279, p 128500.

S. Ghosh and S. Abanteriba, Status of Surface Modification Techniques for Artificial Hip Implants, Sci. Technol. Adv. Mater., 2016, 17(1), p 715–735. https://doi.org/10.1080/14686996.2016.1240575

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This invited article is part of a special topical focus in the Journal of Materials Engineering and Performance on Surface Engineering. The issue was organized by Dr. M.K. Banerjee, Malaviya National Institute of Technology, Jaipur.

Rights and permissions

About this article

Cite this article

Resendiz-Calderon, C.D., Farfan-Cabrera, L.I., Rodríguez-Castro, G.A. et al. Micro-abrasion/Corrosion Behavior of Pack-Borided AISI 316L Steel and ASTM F1537 CoCrMo Alloy in Ceramic-on-Ceramic Couplings. J. of Materi Eng and Perform 30, 3955–3967 (2021). https://doi.org/10.1007/s11665-021-05641-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-05641-3