Abstract

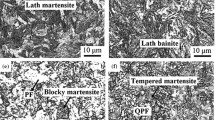

The advanced microstructure of the elongated grain structure with intensive texture, which mainly consists of \(\left\{ {112} \right\}\left\langle {110} \right\rangle_{\alpha } \,{\text{and}}\,\left\{ {332} \right\}\left\langle {113} \right\rangle_{\alpha }\) components, significantly improves the toughness of 1.5 GPa ultra-high strength steel by delamination toughening. The elongated grain structure with texture affects the microstructure evolution of heat affected zone (HAZ), resulting in the refinement of coarse-grained HAZ(CGHAZ), the separate distribution of granular bainite and lath martensite in fine-grained HAZ (FGHAZ) and the formation of clustered blocky martensite in intercritical HAZ (ICHAZ). In ICHAZ, the sharp \(\left\{ {112} \right\}\left\langle {100} \right\rangle_{\alpha }\) of untransformed grains does not undergo reorientation for high thermal stability. For transformed grains, initial \(\left\{ {112} \right\}\left\langle {110} \right\rangle_{\alpha } \,{\text{and}}\,\left\{ {332} \right\}\left\langle {113} \right\rangle_{\alpha }\) components are reproduced by texture heredity. However, with the increase of peak temperature, the heredity tendency of texture weakens, causing the reduction of texture intensity. In CGHAZ, the Goss and \(\left\{ {112} \right\}\left\langle {110} \right\rangle_{\alpha }\) texture are obtained because of grains oriented growth. It is found that serious and heterogenous HAZ softening is a significant feature. FGHAZ becomes the weakest zone due to the massive formation of granular bainite. Due to the disappearance of \(\,\left\{ {332} \right\}\left\langle {113} \right\rangle_{\alpha }\) and the formation of Goss texture, CGHAZ shows the least modulus.

Similar content being viewed by others

References

Z.B. Jiao, J.H. Luan, M.K. Miller, Y.W. Chung, and C.T. Liu: Mater. Today., 2017, vol. 20, pp. 142–54. https://doi.org/10.1016/j.mattod.2016.07.002.

L. Liu, Q. Yu, Z. Wang, J. Ell, and R.O. Ritchie: Science, 2020, vol. 368, pp. 1347–52. https://doi.org/10.1126/science.aba9413.

J. Sun, H. Wang, B. Xu, L. Jiang, S. Guo, X. Sun, D. Yu, F. Liu, and Y. Liu: Acta. Mater., 2022, vol. 227, p. 117701. https://doi.org/10.1016/j.actamat.2022.117642.

Y. Kimura, T. Inoue, F. Yin, and K. Tsuzaki: Science, 2008, vol. 320, pp. 1057–60. https://doi.org/10.1126/science.1156084.

X. Shen, D.Z. Li, S. Tang, J. Chen, H. Fang, and G. Wang: Mater. Sci. Eng. A, 2019, vol. 766, p. 138342. https://doi.org/10.1016/j.msea.2019.138342.

J. Kang, C. Li, G. Yuan, and G. Wang: Mater. Lett., 2016, vol. 175, pp. 157–60. https://doi.org/10.1016/j.matlet.2016.04.007.

M. Tümer, C. Schneider-Bröskamp, and N. Enzinger: J. Manuf. Process., 2022, vol. 82, pp. 203–29. https://doi.org/10.1016/j.jmapro.2022.07.049.

S.H.M. Anijdan, M. Aghaie-Khafri, H.R. Jafarian, and A.R. Khoshakhlagh: Sci. Technol. Weld. Join., 2017, vol. 23, pp. 387–93. https://doi.org/10.1080/13621718.2017.1401337.

P. Yan, Ö.E. Guüngör, P. Thibaux, and H.K.D.H. Bhadeshia: Sci. Technol. Weld. Join., 2013, vol. 15, pp. 137–41. https://doi.org/10.1179/136217109X12568132624163.

S. Mitra, K.S. Arora, B. Bhattacharya, and S.B. Singh: Metall. Mater. Trans. A, 2020, vol. 51A, pp. 2915–26. https://doi.org/10.1007/s11661-020-05747-8.

J. Capek, M. Cernik, N. Ganev, K. Trojan, J. Nemecek, and K. Kolarik: IOP Conf. Ser., 2018, vol. 375, p. 012025. https://doi.org/10.1088/1757-899x/375/1/012025.

S. Mandal, N.K. Tewary, S.K. Ghosh, D. Chakrabarti, and S. Chatterjee: Mater. Sci. Eng. A, 2016, vol. 663, pp. 126–40. https://doi.org/10.1016/j.msea.2016.03.127.

R. Badji, B. Cheniti, C. Kahloun, T. Chauveau, M. Hadji, and B. Bacroix: Int. J. Adv. Manuf. Technol., 2021, vol. 116, pp. 1115–32. https://doi.org/10.1007/s00170-021-07502-8.

G. He, T. Peng, B. Jiang, X. Hu, Y. Liu, and C. Wu: Steel. Res. Int., 2021, vol. 92, p. 2100047. https://doi.org/10.1002/srin.202100047.

R. Song, D. Ponge, D. Raabe, and R. Kaspar: Acta. Mater., 2005, vol. 53, pp. 845–58. https://doi.org/10.1016/j.actamat.2004.10.051.

S. Takajo, C.C. Merriman, S.C. Vogel, and D.P. Field: Acta. Mater., 2019, vol. 166, pp. 100–12. https://doi.org/10.1016/j.actamat.2018.11.054.

H. Cao, X. Luo, G. Zhan, and S. Liu: Metall. Mater. Trans. A, 2017, vol. 48A, pp. 4403–10. https://doi.org/10.1007/s11661-017-4200-0.

M. Niu, G. Zhou, W. Wang, M.B. Shahzad, Y. Shan, and K. Yang: Acta. Mater., 2019, vol. 179, pp. 296–307. https://doi.org/10.1016/j.actamat.2019.08.042.

W. Hou, Q. Liu, H. Wen, and J. Gu: Metall. Mater. Trans. A, 2020, vol. 51A, pp. 3981–4039. https://doi.org/10.1007/s11661-020-05811-3.

X. Zhang, X. Di, W. Jing, X. Zhou, C. Zhang, and C. Li: Steel. Res. Int., 2022, vol. 93, p. 2100776. https://doi.org/10.1002/srin.202100776.

M. Amraei, S. Afkhami, V. Javaheri, J. Larkiola, T. Skriko, T. Björk, and X.L. Zhao: Thin. Wall. Struct., 2020, vol. 157, p. 107072. https://doi.org/10.1016/j.engstruct.2019.109460.

X. Di, M. Tong, C. Li, C. Zhao, and D.P. Wang: Mater. Sci. Eng. A, 2019, vol. 743, pp. 67–76. https://doi.org/10.1016/j.msea.2018.11.070.

R.K. Ray and J.J. Jonas: Int. Mater. Rev., 1990, vol. 35, pp. 1–36. https://doi.org/10.1179/095066090790324046.

D. Zhuang, L. Wang, Y. Huang, X. Li, H. Zhang, and D. Ren: J. Iron. Steel. Res. Int., 2017, vol. 24, pp. 84–90. https://doi.org/10.1016/S1006-706X(17)30012-2.

G. Niu, H.S. Zurob, R.D. Misra, Q. Tang, Z. Zhang, M.T. Nguyen, L. Wang, H. Wu, and Y. Zou: Acta. Mater., 2022, vol. 226, p. 117642. https://doi.org/10.1016/j.actamat.2022.117642.

M. Baek, K. Kim, T. Park, J. Ham, and K. Lee: Mater. Sci. Eng. A, 2020, vol. 785, p. 139375. https://doi.org/10.1016/j.msea.2020.139375.

A. Elramady, E. Sullivan, K. Sham, L. O’Brien, and S. Liu: Weld. World., 2021, vol. 66, pp. 195–211. https://doi.org/10.1007/s40194-021-01216-x.

S. Afkhami, V. Javaheri, M. Amraei, T. Skriko, H. Piili, X.L. Zhao, and T. Björk: Mater. Design., 2022, vol. 213, p. 110336. https://doi.org/10.1016/j.matdes.2021.110336.

C. Fang, C. Li, F. Ji, W. Fu, W. Hu, and X. Di: Materials, 2023, vol. 16, p. 550. https://doi.org/10.3390/ma16020550.

F. Fang, Y. Zhao, L. Zhou, X. Hu, Z. Xie, and J. Jiang: Mater. Sci. Eng. A, 2014, vol. 618, pp. 505–10. https://doi.org/10.1016/j.msea.2014.09.061.

S. Danilov, I. Semkina, I. Pyshmintsev, and M. Lobanov: IOP Conf. Ser., 2019, vol. 613, pp. 8–12. https://doi.org/10.1088/1757-899x/613/1/012006.

M.L. Lobanov, I.Y. Pyshmintsev, V.N. Urtsev, S.V. Danilov, N.V. Urtsev, and A.A. Redikultsev: Phys. Metal Metallogr., 2020, vol. 120, pp. 1180–86. https://doi.org/10.1134/s0031918x1912010x.

M. Mehdi, Y. He, E.J. Hilinski, L.A.I. Kestens, and A. Edrisy: Steel. Res. Int., 2019, vol. 90, p. 1800582. https://doi.org/10.1002/srin.201800582.

J.L. Caron, S.S. Babu, and J.C. Lippold: Metall. Mater. Trans. A, 2011, vol. 42A, pp. 4015–31. https://doi.org/10.1007/s11661-011-0801-1.

A.H. Hunter, J.D. Farren, J.N. DuPont, and D.N. Seidman: Metall. Mater. Trans. A, 2012, vol. 44A, pp. 1741–59. https://doi.org/10.1007/s11661-012-1518-5.

A. Zareidoost and M. Yousefpour: Mater. Lett., 2020, vol. 259, p. 126876. https://doi.org/10.1016/j.matlet.2019.126876.

C. Lan, Y. Wu, L. Guo, and F. Chen: Mater. Sci. Eng. A, 2017, vol. 690, pp. 170–76. https://doi.org/10.1016/j.msea.2017.02.045.

Acknowledgments

The authors gratefully acknowledge the financial support from the National Natural Science Foundation of China (Grant No. 52274391), Natural Science Foundation of Fujian Province (Grant No. 2021J05232) and Qimai Foundation of Shanghang County (Grant No. 2020SHQM05).

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Fang, C., Li, C., Di, X. et al. Evolution of Microstructure and Crystallographic Texture During Welding for 1.5 GPa Ultra-high Strength Steel Toughened by an Elongated Grain Structure With Intensive Texture. Metall Mater Trans A 54, 3055–3068 (2023). https://doi.org/10.1007/s11661-023-07061-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-023-07061-5