Abstract

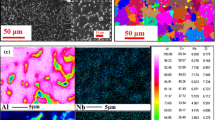

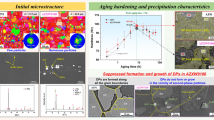

In this work, the effects of Ca, Sn, and Zn additions on the creep resistance of Mg–Al-based alloys were systematically traced at 453 K. The best creep resistance was obtained in Mg–6Al–1Ca (AX61) alloy followed by Mg–6Al–1Zn (AZ61) and Mg–6Al–1Sn (AT61) alloys, albeit the highest yield stress was obtained in AZ61 alloy at both room temperature and creep temperature. Specifically, for AT61 alloy, unsharp solution strengthening, ineffective precipitation strengthening, and long slip traces derived from prismatic 〈a〉 dislocations were responsible for the fastest creep rate and the most diminished creep resistance. For AZ61 alloy, the highest fraction of dynamic precipitates was achieved, creating the most serious depletion of solution strengthening. But due to the close connection between precipitates and dislocations, the effective precipitation strengthening avoided the weak creep resistance like the case in AT61 alloy. For AX61 alloy, strong solution strengthening and stable dislocation networks composed by prismatic 〈a〉 dislocations simultaneously reduced the creep rate. The limited loss of solution strengthening and the interrupted basal slip transitivity between neighboring grains also enhanced the creep resistance. Thus, it is strongly recommended that adding Ca element into Mg–Al-based alloys has a positive effect on the creep resistance via controlling solution strengthening and dislocation morphologies.

Similar content being viewed by others

References

Q. Huo, X. Yang, J. Ma, H. Sun, J. Qin, and Y. Jiang: Mater. Charact., 2013, vol. 29, pp. 43–51.

J.U. Lee, Y.J. Kim, and S.H. Park: Mater. Sci. Eng. A, 2022, vol. 854, p. 143814.

A. Jamali, A. Ma, and J. LLorca: Acta Mater., 2022, vol. 239, p. 118263.

T. Chen, S. Hu, S. Li, and Q. Huo: Mater. Sci. Eng. A, 2022, vol. 857, p. 144056.

P. Nautiyal, J. Jain, and A. Agarwal: Mater. Sci. Eng. A, 2015, vol. 630, pp. 131–38.

S. Spigarelli: Scripta Mater., 2000, vol. 42, pp. 397–402.

J.F. Nie: Scripta Mater., 2003, vol. 48, pp. 1009–15.

B. Amir Esgandari, H. Mehrjoo, B. Nami, and S.M. Miresmaeili: Mater. Sci. Eng. A, 2011, vol. 528, pp. 5018–24.

S.M. Ashrafizadeh, R. Mahmudi, and A.R. Geranmayeh: Mater. Sci. Eng. A, 2020, vol. 790, p. 139712.

N. Kashefi and R. Mahmudi: Mater. Des., 2012, vol. 39, pp. 200–10.

A.R. Geranmayeh and R. Mahmudi: Mater. Sci. Eng. A, 2014, vol. 614, pp. 311–18.

J. Majhi and A.K. Mondal: Mater. Sci. Eng. A, 2019, vol. 744, pp. 691–703.

C.R. Hutchinson, J.F. Nie, and S. Gorsse: Metall. Mater. Trans. A, 2005, vol. 36A, pp. 2093–2105.

P. Hidalgo-Manrique and J.D. Robson: Metall. Mater. Trans. A, 2019, vol. 50A, pp. 3855–67.

S.M. Ashrafizadeh and R. Mahmudi: Metall. Mater. Trans. A, 2019, vol. 50A, pp. 5957–68.

F. Khomamizadeh, B. Nami, and S. Khoshkhooei: Metall Mater. Trans. A, 2005, vol. 36A, pp. 3489–94.

F. Kabirian and R. Mahmudi: Metall. Mater. Trans. A, 2010, vol. 41A, pp. 3488–98.

T. Nakata, C. Xu, R. Ajima, K. Shimizu, S. Hanaki, T.T. Sasaki, L. Ma, K. Hono, and S. Kamado: Acta Mater., 2017, vol. 130, pp. 261–70.

M.R. Sahu, T.S.S. Kumar, and U. Chakkingal: J. Magnesium Alloys, 2022, vol. 10, pp. 2094–2117.

S. Li, Q. Huo, S. Hu, C. Wang, Z. Zhang, Y. Zhang, T. Chen, and X. Yang: Mater. Charact., 2023, vol. 195, p. 112534.

J. Li, X. Zhou, J. Su, B. Breitbach, M.L. Chwałek, H. Wang, and G. Dehm: Mater. Sci. Eng. A, 2022, vol. 856, p. 143898.

T.T. Sasaki, K. Oh-ishi, T. Ohkubo, and K. Hono: Scripta Mater., 2006, vol. 55, pp. 251–54.

T.T. Sasaki, K. Oh-ishi, T. Ohkubo, and K. Hono: Mater. Sci. Eng. A, 2011, vol. 530, pp. 1–8.

R.E. Schäublin, M. Becker, M. Cihova, S.S.A. Gerstl, D. Deiana, C. Hébert, S. Pogatscher, P.J. Uggowitzer, and J.F. Löffler: Acta Mater., 2022, vol. 239, p. 118223.

B. Kondori and R. Mahmudi: Mater. Sci. Eng. A, 2017, vol. 700, pp. 438–47.

M.A. Gibson, X. Fang, C.J. Bettles, and C.R. Hutchinson: Scripta Mater., 2010, vol. 63, pp. 899–902.

D.H. Kang, S.S. Park, and N.J. Kim: Mater. Sci. Eng. A, 2005, vol. 413–414, pp. 555–60.

J. Miao, C. Zhang, A.D. Klarner, J. Zhang, E. Cinkilic, F. Zhang, and A.A. Luo: Materialia, 2022, vol. 21, p. 101348.

J. Li, X. Zhou, A. Breen, Z. Peng, J. Su, P. Kürnsteiner, M.J.D. Correa, M.L. Chwałek, H. Wang, D. Holec, J. Mayer, and G. Dehm: J. Alloys Compd., 2022, vol. 928, p. 167177.

A.A. Luo, P. Fu, L. Peng, X. Kang, Z. Li, and T. Zhu: Metall. Mater. Trans. A, 2012, vol. 43A, pp. 360–68.

A.S.H. Kabir, M. Sanjari, J. Su, I. Jung, and S. Yue: J. Mater. Sci., 2016, vol. 51, pp. 1600–09.

S.M. Zhu, B.L. Mordike, and J.F. Nie: Mater. Sci. Eng. A, 2008, vol. 483–484, pp. 583–86.

B.H. Kim, K.C. Park, Y.H. Park, and I.M. Park: Mater. Sci. Eng. A, 2011, vol. 528, pp. 808–14.

A. Bahmani, S. Arthanari, and K.S. Shin: J. Magnesium Alloys, 2019, vol. 7, pp. 38–46.

S. Avraham, A. Katsman, and M. Bamberger: J. Mater. Sci., 2011, vol. 46, pp. 6941–51.

T. Nakata, C. Xu, Y. Uehara, T.T. Sasaki, and S. Kamado: J. Alloys Compd., 2019, vol. 782, pp. 304–14.

X. Huang, K. Suzuki, Y. Chino, and M. Mabuchi: J. Alloys Compd., 2015, vol. 632, pp. 94–102.

Y. Zhang, T. Chen, J. Kuang, and Q. Huo: Metall. Mater. Trans. A, 2022, vol. 3A, pp. 747–53.

C. Wang, Y. Zhang, Q. Huo, Z. Zhang, J. Tang, A. Hashimoto, and X. Yang: Mater. Sci. Eng. A, 2021, vol. 800, p. 140309.

S. Hu, Q. Huo, C. Wang, Y. Zhang, Z. Zhang, S. Xu, and X. Yang: J. Alloys Compd., 2022, vol. 895, p. 162666.

Y. Zhang, Q. Huo, Z. Zhang, C. Wang, H. Nagaumi, and X. Yang: Mater. Sci. Eng. A, 2022, vol. 839, p. 142894.

D. Nagarajan: Mater. Sci. Eng. A, 2022, vol. 860, p. 144292.

B. Kim, B. Kang, Y. Park, and I. Park: Mater. Sci. Eng. A, 2011, vol. 528, pp. 5747–53.

S.M. Jo, S.D. Kim, T. Kim, Y. Go, C. Yang, B.S. You, and Y.M. Kim: J. Alloys Compd., 2018, vol. 749, pp. 794–802.

N. Li, C. Wang, M.A. Monclús, L. Yang, and J.M. Molina-Aldareguia: Acta Mater., 2021, vol. 221, p. 117374.

H.S. Kim and W.J. Kim: Corros. Sci., 2013, vol. 75, pp. 228–38.

M.R. Barnett, Z. Keshavarz, A.G. Beer, and D. Atwell: Acta Mater., 2004, vol. 52, pp. 5093–5103.

A. Jain, O. Duygulu, D.W. Brown, C.N. Tomé, and S.R. Agnew: Mater. Sci. Eng. A, 2008, vol. 486, pp. 545–55.

G. Li, J. Zhang, R. Wu, S. Liu, B. Song, Y. Jiao, Q. Yang, and L. Hou: J. Alloys Compd., 2019, vol. 777, pp. 1375–85.

L. Gao, R.S. Chen, and E.H. Han: J. Alloys Compd., 2009, vol. 481, pp. 379–84.

S. Abaspour, V. Zambelli, M. Dargusch, and C.H. Cáceres: Mater. Sci. Eng. A, 2016, vol. 673, pp. 114–21.

B.Q. Shi, R.S. Chen, and W. Ke: J. Alloys Compd., 2011, vol. 509, pp. 3357–62.

J. Miao, W. Sun, A.D. Klarner, and A.A. Luo: Scripta Mater., 2018, vol. 154, pp. 192–96.

M. Sarebanzadeh, A. Orozco-Caballero, and J. LLorca: Acta Mater., 2023, vol. 243, p. 118536.

C.M. Cepeda-Jiménez, J.M. Molina-Aldareguia, and M.T. Pérez-Prado: Acta Mater., 2015, vol. 88, pp. 232–44.

Z. Zhang, Q. Huo, Z. Xiao, Y. Zhang, K. Li, H. Nagaumi, and X. Yang: J. Mater. Sci., 2022, vol. 57, pp. 2229–42.

J. Li, J. Wu, L. Jin, M. Celikin, F. Wang, S. Dong, and J. Dong: Sci. Rep., 2021, vol. 11, p. 2860.

Y. Liu, J. Yan, D. Xie, Y. Shen, J. Wang, and G. Zhu: Scripta Mater., 2021, vol. 191, pp. 86–89.

D. Zhao, X. Ma, S. Picak, I. Karaman, and K. Xie: Scripta Mater., 2020, vol. 179, pp. 49–54.

C. Wang, H. Zhang, H. Wang, G. Liu, and Q. Jiang: Scripta Mater., 2013, vol. 69, pp. 445–48.

Acknowledgments

The authors gratefully acknowledge the financial supports received from the National Natural Science Foundation of China (Grant Nos. 51974376 and 52071344), the Natural Science Foundation of Hunan Province (Grant No. 2021JJ20063), and the Distinguished Professor Project of Central South University (Grant No. 202045009).

Conflict of interest

The authors declare that they have no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chen, T., Huo, Q., Hu, S. et al. Tracing the Effects of Calcium, Stannum, and Zinc Additions on the Creep Resistance of Mg–Al-Based Alloys. Metall Mater Trans A 54, 2730–2743 (2023). https://doi.org/10.1007/s11661-023-07050-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-023-07050-8