Abstract

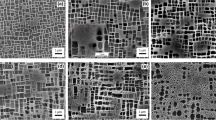

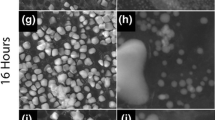

Experiments were undertaken to understand forging and heat treatment conditions that give rise to large, visible grains in a new polycrystalline nickel-based γ–γ′ superalloy after solution heat treatment above the gamma prime (γ′) solvus temperature (Tsolvus). Such grains are undesirable as they reduce strength and low cycle fatigue performance. The information that is reported is required to design an isothermal forging practice to manufacture closed die forgings, intended for disk rotors that are used in aircraft engines. The alloy is a development composition, which contains about 51 pct γ′ and has been produced by powder metallurgy. Compression tests were conducted to specified upsets on right circular cylinder and double-cone test pieces. Segments of double cones were heat treated and examined to characterize grain size. Visible grains were found in areas of low forging strain (< 0.75), particularly in localized areas of higher strain rate, from slow heating rates through the γ′ Tsolvus. It is proposed that they are produced by selective grain growth from activation of a limited number of recrystallization nuclei that have sufficient retained strain energy to exceed a critical value, which reduces with increasing heating time. Higher strains are understood to promote the formation of additional nucleation sites for recrystallization and a consistently finer grain size. Localized areas of low strain that receive higher strain rates generate greater strain hardening, which creates a higher number of nuclei for selective grain growth, compared to surrounding regions.

Similar content being viewed by others

Change history

30 January 2023

A Correction to this paper has been published: https://doi.org/10.1007/s11661-023-06971-8

References

P. Argüelles, J. Lumsden, M. Bischoff, D. Ranque, P. Busquin, S. Rasmussen, B.A.C. Droste, P. Reutlinger, R. Evans, R. Robins, W. Kröll, H. Terho, J.-L. Lagardère, A. Wittlöv, and A. Lina: European Aeronautics: A Vision for 2020 (Advisory Council for Aviation Research and Innovation in Europe), https://op.europa.eu/en/publication-detail/-/publication/214b7682-3947-411f-bcb5-92cb03ea7931. Accessed 13 August 2022.

M. Darecki, C. Edelstenne, T. Enders, E. Fernandez, P. Hartman, J.-P. Herteman, M. Kerkloh, I. King, P. Ky, M. Mathieu, G. Orsi, G. Schotman, C. Smith, and J.-D. Worner: Flightpath 2050 Europe’s Vision for Aviation (European Commission), https://op.europa.eu/en/publication-detail/-/publication/7d834950-1f5e-480f-ab70-ab96e4a0a0a. Accessed 13 August 2022.

R.C. Reed, A. Mottura, and D.J. Crudden: in Superalloys 2016, M. Hardy, E. Huron, U. Glatzel, B. Griffin, B. Lewis, C. Rae, V. Seetharaman, and S. Tin, eds., TMS, Warrendale, PA, 2016, pp. 15–23.

R.J. Mitchell, J.A. Lemsky, R. Ramanathan, H.Y. Li, K.M. Perkins, and L.D. Connor: in Superalloys 2008, R.C. Reed, K.A. Green, P. Caron, T. Gabb, M.G. Fahrmann, E.S. Huron, and S.A. Woodard, eds., TMS, Warrendale, PA, 2008, pp. 347–56.

D. Anderson: Fuel Conservation Operational Procedures for Environmental Performance (International Civil Aviation Organisation), https://www.icao.int/Meetings/EnvironmentalWorkshops/Documents/ICAO-TransportCanada-2006/Anderson_ops.pdf. Accessed 13 August 2022.

M.C. Hardy, C. Argyrakis, H.S. Kitaguchi, A.S. Wilson, R.C. Buckingham, K. Severs, S. Yu, C. Jackson, E.J. Pickering, S.C.H. Llewelyn, C. Papadaki, K.A. Christofidou, P.M. Mignanelli, A. Evans, D.J. Child, H.Y. Li, N.G. Jones, C.M.F. Rae, P. Bowen, and H.J. Stone: in Superalloys 2020, S. Tin, M. Hardy, J. Clews, J. Cormier, Q. Feng, J. Marcin, C. O’Brien, and A. Suzuki, eds., The Minerals, Metals & Materials Series, Warrendale, PA, 2020, pp. 19–30. https://doi.org/10.1007/978-3-030-51834-9_2.

R.L. Dreshfield, and H.R. Gray: P/M Superalloys – A Troubled Adolescent, NASA Technical Memorandum, TM-83623, Lewis Research Center, Cleveland, OH, June 1984.

R. Anderson: Int. J. Powder Metall., 1990, vol. 26(2), pp. 171–78.

J. Smythe: Advanced Materials and Processes, November 2008, pp. 52–5. https://www.asminternational.org/documents/10192/1887146/amp16611p052.pdf/6664af73-fa87-4c2f-8b94-d420d5c438e3/AMP16611P052. Accessed 13 August 2022.

M.C. Hardy, M. Detrois, E.T. McDevitt, C. Argyrakis, V. Saraf, P.D. Jablonski, J.A. Hawk, R.C. Buckingham, H.S. Kitaguchi, and S. Tin: Metall. Mater. Trans. A, 2020, vol. 51A, pp. 2626–50.

N. Bozzolo, A. Agnoli, N. Souai, M. Bernacki, and R.E. Loge: 5th Int. Conf. Recryst. Grain Growth. Sydney, 2013. https://doi.org/10.4028/www.scientific.net/MSF.753.321.

A. Agnoli, M. Bernacki, R. Logé, J.-M. Franchet, J. Laigo, and N. Bozzolo: Metall. Mater. Trans. A, 2015, vol. 46A, pp. 4405–21.

V.M. Miller, A.E. Johnson, C.J. Torbet, and T.M. Pollock: Metall. Mater. Trans. A, 2016, vol. 47A, pp. 1566–74.

M.C. Hardy, R.C. Reed, and D. Crudden: United States Patent US 10,422,024 B2, 24 September 2019.

M. Brozovic Gariglio, N. Bozzolo, and D. Pino Muñoz: Metall. Mater. Trans. A, 2021, vol. 52A, pp. 4125–36.

G.J. Davies, J.W. Edington, C.P. Cutler, and K.A. Padmanabhan: J. Mater. Sci., 1970, vol. 5(12), pp. 1091–102.

F. Liu, J. Chen, J. Dong, M. Zhang, and Z. Yao: Mater. Sci. Eng. A, 2016, vol. 651, pp. 102–15.

M.J. Anderson, F. Schulz, Y. Lu, H.S. Kitaguchi, P. Bowen, C. Argyrakis, and H.C. Basoalto: Acta Mater., 2020, vol. 191, pp. 81–100.

T.P. Gabb, A. Garg, D.R. Miller, C.K. Sudbrack, D.R. Hull, D. Johnson, R.B. Rogers, J. Gayda, and S.L. Semiatin, Formation of Minor Phases in a Nickel-Based Disk Superalloy, NASA Technical Memorandum TM-2012-217604, Glenn Research Center, Cleveland, OH, 2012.

L. Tan, Y. Li, F. Liu, Y. Nie, and L. Jiang: J. Mater. Sci. Technol., 2019, vol. 35, pp. 2591–99.

J. Gayda, P. Kantzos, and J. Miller: Quench Crack Behavior of Nickel-Based Disk Superalloys, NASA/TM-2002-211994, NASA Technical Memorandum TM-2002-211984, Glenn Research Center, Cleveland, OH, 2002.

Y.K. Cho, D.Y. Yoon, and M.F. Henry: Metall. Mater. Trans. A, 2001, vol. 32A, pp. 3077–90.

M. Detrois, J. Rotella, R.L. Goetz, R.C. Helmink, and S. Tin: Mater. Sci. Eng. A, 2015, vol. 627, pp. 95–105.

R. Thamburaj, A.K. Koul, W. Wallace, and M.C. de Malherbe: Proc. 1984 Int. Powder Metall. Conf., Int. Powder Metall. Conf., E.N. Aqua, and C.I. Whitman, eds., MPIF/APMI, 1985, pp. 635–75.

G.L.G.S.B. Srinivas Kumar, M. Sateshwar, A. Ranjan Sharma, M. Palit, R. Sarkar, P. Ghosal, and G. Appa Rao: J. Alloys Compd., 2022, vol. 909(7), p. 164772. https://doi.org/10.1016/j.jallcom.2022.164772.

J.R. May, M.C. Hardy, M.R. Bache, and D.D. Kaylor: in Euro Superalloys 2010, M. Hellmaier, eds., 2011, pp. 265–70.

K.A. Christofidou, M.C. Hardy, H.Y. Li, C. Argyrakis, H. Kitaguchi, N.G. Jones, P.M. Mignanelli, A.S. Wilson, O.M.D.M. Messé, E.J. Pickering, R.J. Gilbert, C.M.F. Rae, S. Yu, A. Evans, D. Child, P. Bowen, and H.J. Stone: Metall. Mater. Trans. A, 2018, vol. 49A, pp. 3896–907.

E.J. Payton: Characterization and Modeling of Grain Coarsening in Powder Metallurgy Nickel-Based Superalloys, The Ohio State University, Columbus, 2009.

I.M.D. Parr, T.J. Jackson, M.C. Hardy, D.J. Child, C. Argyrakis, K. Severs, V. Saraf, and J.M. Stumpf: in Superalloys 2016, M. Hardy, E. Huron, U. Glatzel, B. Griffin, B. Lewis, C. Rae, V. Seetharaman, and S. Tin, eds., TMS, Warrendale, PA, 2016, pp. 447–56.

M.A. Charpagne, A.T. Polonsky, M.P. Echlin, S. Jacomet, J. de Jaeger, M. De Graef, N. Bozzolo, and T.M. Pollock: Scripta Mater., 2020, vol. 186, pp. 109–13.

Acknowledgments

This work was supported by Rolls-Royce plc and the Innovate-UK UHTNA and CRUISE projects. Drs Hardy, Buckingham, and Argyrakis would like to thank Rolls-Royce colleague Dr Han Tai for his support and encouragement in this work, Cameron Brett, Zak Lomas of Rolls-Royce, Andrew Wilkinson, and Stuart White of Intertek Derby for sample preparation and electron microscopy. Dr Hardy would also like to acknowledge discussions with Professor Catherine Rae of the University of Cambridge.

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

The original online version of this article was revised: The copyright holder was corrected.

Rights and permissions

About this article

Cite this article

Hardy, M.C., Buckingham, R.C., Severs, K. et al. Forging and Heat Treatment Conditions that Produce Visible Grains in a γ–γ′ Nickel-Based Superalloy. Metall Mater Trans A 54, 2112–2126 (2023). https://doi.org/10.1007/s11661-022-06943-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-022-06943-4