Abstract

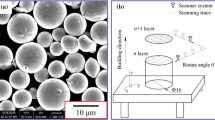

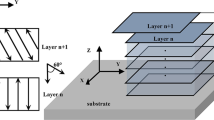

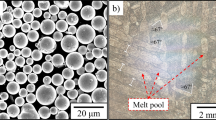

The anisotropic of stress rupture properties of additive manufacturing superalloys at high temperatures affect their further applications in the aerospace field. In this study, selective laser melting (SLM) was used to prepare Inconel 718 blocks with axial direction normal or parallel to the building direction. The microstructure of different specimens was designed by process parameter control and post-processing. Tensile properties of horizontal and vertical specimens were tested at room temperature, and the stress rupture tests were performed at 650 °C under 690 MPa. The relationship between different microstructure and the anisotropy of stress rupture properties was studied. It is found that the grain morphology, grain boundary state and the morphology and location of precipitated phase have strong influence on the anisotropy. After the newly designed post-treatment including HIP + solution + aging, the normal temperature tensile property of vertical and horizontal specimens are maintained at a high level, besides the stress rupture life of vertical and horizontal specimens has the average time reach 173 and 131 hours at high temperature, respectively. This provides a basis for how to reduce the anisotropic stress rupture properties of SLM Inconel 718, which will have a positive impact on its wider application in engineering.

Similar content being viewed by others

References

M. Godec, S. Malej, D. Feizpour, Č Donik, M. Balažic, D. Klobčar, L. Pambaguian, M. Conradi, and A. Kocijan: Mater. Charact., 2021, vol. 172, pp. 110842–58.

D.-H. Kim, J.-H. Kim, J.-W. Sa, Y.-S. Lee, C.-K. Park, and S.-I. Moon: Mater. Sci. Eng. A, 2008, vol. 483–484, pp. 262–65.

Q. Yin, Z. Liu, B. Wang, Q. Song, and Y. Cai: Int. J. Adv. Manuf. Technol., 2020, vol. 109, pp. 215–45.

C. Tan, F. Weng, S. Sui, Y. Chew, and G. Bi: Int. J. Mach. Tools Manuf., 2021, vol. 170, pp. 103804–62.

H.-Y. Wan, Z.-J. Zhou, C.-P. Li, G.-F. Chen, and G.-P. Zhang: Adv. Eng. Mater., 2018, vol. 20, pp. 1800307–13.

D. Deng, R.L. Peng, and J. Moverare: Int. J. Plast., 2021, vol. 140, pp. 102974–90.

L. Huang, Y. Cao, J. Zhang, X. Gao, G. Li, and Y. Wang: J. Alloys Compd., 2021, vol. 865, pp. 158613–32.

T. Trosch, J. Strößner, R. Völkl, and U. Glatzel: Mater. Lett., 2016, vol. 164, pp. 428–31.

D. Zhang, Z. Feng, C. Wang, W. Wang, Z. Liu, and W. Niu: Mater. Sci. Eng. A, 2018, vol. 724, pp. 357–67.

S. Banait, X. Jin, M. Campos, and M.T. Pérez-Prado: Scr. Mater., 2021, vol. 203, pp. 114075–80.

O. Gokcekaya, N. Hayashi, T. Ishimoto, K. Ueda, T. Narushima, and T. Nakano: Addit. Manuf., 2020, vol. 36, pp. 101624–34.

S. Zhang, X. Lin, L. Wang, X. Yu, H. Yang, L. Lei, and W. Huang: Mater. Sci. Eng. A, 2021, vol. 803, pp. 140702–13.

Q. Teng, S. Li, Q. Wei, and Y. Shi: J. Manuf. Processes, 2021, vol. 61, pp. 35–45.

N. Kouraytem, J. Varga, B. Amin-Ahmadi, H. Mirmohammad, R.A. Chanut, A.D. Spear, and O.T. Kingstedt: Mater. Des., 2021, vol. 198, pp. 109228–40.

M. Ni, C. Chen, X. Wang, P. Wang, R. Li, X. Zhang, and K. Zhou: Mater. Sci. Eng. A, 2017, vol. 701, pp. 344–52.

W.M. Tucho and V. Hansen: Metals, 2021, vol. 11, pp. 266–85.

X. Li, J.J. Shi, G.H. Cao, A.M. Russell, Z.J. Zhou, C.P. Li, and G.F. Chen: Mater. Des., 2019, vol. 180, pp. 107915–23.

V.A. Popovich, E.V. Borisov, A.A. Popovich, V.S. Sufiiarov, D.V. Masaylo, and L. Alzina: Mater. Des., 2017, vol. 131, pp. 12–22.

D.J. Newell, R.P. O’Hara, G.R. Cobb, A.N. Palazotto, M.M. Kirka, L.W. Burggraf, and J.A. Hess: Mater. Sci. Eng. A, 2019, vol. 764, pp. 138230–41.

J. Cormier, P. Gadaud, M. Czaplicki, R.Y. Zhang, H.B. Dong, T.M. Smith, F. Zhang, J.S. Tiley, and S.L. Semiatin: Metall. Mater. Trans. A, 2020, vol. 52, pp. 500–11.

J.-P. Choi, G.-H. Shin, S. Yang, D.-Y. Yang, J.-S. Lee, M. Brochu, and J.-H. Yu: Powder Technol., 2017, vol. 310, pp. 60–66.

G.H. Cao, T.Y. Sun, C.H. Wang, X. Li, M. Liu, Z.X. Zhang, P.F. Hu, A.M. Russell, R. Schneider, D. Gerthsen, Z.J. Zhou, C.P. Li, and G.F. Chen: Mater. Charact., 2018, vol. 136, pp. 398–406.

R. Jiang, A. Mostafaei, Z. Wu, A. Choi, P.-W. Guan, M. Chmielus, and A.D. Rollett: Addit. Manuf., 2020, vol. 35, pp. 101282–95.

A. Hilaire, E. Andrieu, and X. Wu: Addit. Manuf., 2019, vol. 26, pp. 147–60.

P. Li, J. Zhou, Y. Gong, X. Meng, and J. Lu: J. Mech. Sci. Technol., 2021, vol. 35, pp. 2871–78.

P. Fernandez-Zelaia, Y. Lee, S. Dryepondt, and M.M. Kirka: Int. J. Plast., 2022, vol. 151, pp. 103177–204.

J. Xu, P. Kontis, R.L. Peng, and J. Moverare: Acta Mater., 2022, vol. 240, pp. 118307–27.

P. Pant, S. Proper, V. Luzin, S. Sjöström, K. Simonsson, J. Moverare, S. Hosseini, V. Pacheco, and R.L. Peng: Addit. Manuf., 2020, vol. 36, pp. 101501–18.

Z. Xu, J.W. Murray, C.J. Hyde, and A.T. Clare: Addit. Manuf., 2018, vol. 24, pp. 486–97.

Z. Xu, L. Cao, Q. Zhu, C. Guo, X. Li, X. Hu, and Z. Yu: Mater. Sci. Eng. A, 2020, vol. 794, pp. 139947–58.

D.B. Witkin, R.W. Hayes, T.D. McLouth, and G.E. Bean: Metall. Mater. Trans. A, 2019, vol. 50, pp. 3458–65.

L. Xu, Z. Chai, H. Chen, X. Zhang, J. Xie, and X. Chen: Mater. Sci. Eng. A, 2021, vol. 824, pp. 141822–38.

S. Zhang, L. Wang, X. Lin, H. Yang, M. Li, L. Lei, and W. Huang: Compos. B, 2021, vol. 224, pp. 109202–12.

J.J. Shi, S.A. Zhou, H.H. Chen, G.H. Cao, A.M. Russell, Z.J. Zhou, X.B. Qi, C.P. Li, and G.F. Chen: Mater. Sci. Eng. A, 2021, vol. 805, pp. 140583–94.

Z. Zhang, J.C. Khong, B. Koe, S. Luo, S. Huang, L. Qin, S. Cipiccia, D. Batey, A.J. Bodey, C. Rau, Y.L. Chiu, Z. Zhang, J.-C. Gebelin, N. Green, and J. Mi: Scr. Mater., 2021, vol. 193, pp. 71–76.

Z. Zhang, Z. Yang, S. Lu, A. Harte, R. Morana, and M. Preuss: Nat. Commun., 2020, vol. 11, pp.

F. Theska, A. Stanojevic, B. Oberwinkler, S.P. Ringer, and S. Primig: Acta Mater., 2018, vol. 156, pp. 116–24.

M. Ni, S. Liu, C. Chen, R. Li, X. Zhang, and K. Zhou: Mater. Sci. Eng. A, 2019, vol. 748, pp. 275–85.

X. Yu, X. Lin, H. Tan, Y. Hu, S. Zhang, F. Liu, H. Yang, and W. Huang: Int. J. Fatigue, 2021, vol. 143, pp. 106005–18.

S. Sanchez, G. Gaspard, C.J. Hyde, I.A. Ashcroft, R. G.A, and A.T. Clare: Mater. Des., 2021, vol. 204, pp. 109647–64.

W. Chen and M.C. Chaturvedi: Acta Mater., 1997, vol. 45, pp. 2735–46.

W. Shifeng, L. Shuai, W. Qingsong, C. Yan, Z. Sheng, and S. Yusheng: J. Mater. Process. Technol., 2014, vol. 214, pp. 2660–67.

S. Sui, J. Chen, L. Ma, W. Fan, H. Tan, F. Liu, and X. Lin: J. Alloys Compd., 2019, vol. 770, pp. 125–35.

Q. Han, Y. Gu, R. Setchi, F. Lacan, R. Johnston, S.L. Evans, and S. Yang: Addit. Manuf., 2019, vol. 30, pp. 100919–930.

A.R. Balachandramurthi, J. Moverare, T. Hansson, and R. Pederson: Int. J. Fatigue, 2020, vol. 141, pp. 105898–5910.

S. Goel, E. Zaninelli, T. Gundgire, M. Ahlfors, O. Ojo, U. Klement, and S. Joshi: Mater. Sci. Eng. A, 2021, vol. 820, pp. 141515–31.

T.N. Palleda, S. Banoth, Y.-L. Kuo, and K. Kakehi: Metals, 2022, vol. 12, pp. 446–58.

G.W.S. Christopher, F. Miller, and R.P. Wei: Scr. Mater., 2000, vol. 42, pp. 227–32.

T.D. McLouth, D.B. Witkin, J.R. Lohser, G.E. Bean, S.D. Sitzman, P.M. Adams, J.-M. Yang, and R.J. Zaldivar: J. Mater. Eng. Perform., 2021, vol. 30, pp. 4882–90.

Acknowledgments

The authors would like to acknowledge the Science and Technology on Reactor Fuel and Materials Laboratory and the National Key Project of Research and Development Program of China (2018YFB1900105).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding authors state that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

He, S., Guo, S. & Xu, Y. Anisotropic Stress Rupture Properties-Microstructure Relationships in SLM Inconel 718 Alloy. Metall Mater Trans A 54, 1776–1791 (2023). https://doi.org/10.1007/s11661-022-06872-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-022-06872-2