Abstract

Bi–Cu alloys may potentially be used for thermal energy storage or as a catalyst for methane pyrolysis. For application research and simulations, it is necessary to know the reliable thermophysical properties of liquid alloys. Density of liquid Bi–Cu alloys (25, 50, 75 at. pct Cu) was measured with dilatometric method over the 971 K to 1500 K range. Density decreases linearly with temperature for all compositions. The molar volume calculated from measured densities shows positive excess molar volume. Surface tension was measured with maximum bubble pressure method over the 1125 K to 1500 K range. The data fitted with linear equations show that while the surface tension of 25 at. pct Cu decreases and that of 50 at. pct Cu alloy does not vary with temperature, the surface tension of 75 at. pct Cu alloy increases with temperature. The present results are confronted with literature data and several model calculations, part of which were performed in Pandat, and the reasons for positive excess molar volume and surface tension temperature coefficient are explained in terms of thermodynamics of Bi–Cu solutions.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

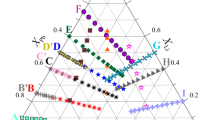

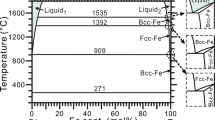

Bi–Cu system (Figure 1) is a simple eutectic system with a convex shape of liquidus[1,2,3] and eutectic point close to pure Bi (eutectic temperature 543.8 K). Melting temperature (\({T}_{\text{M}}\)) of Cu (1357.8 K) is much higher compared to the \({T}_{\text{M}}\) of Bi (544.6 K), and mutual solubilities in the solid are negligible. The demixing tendency in the liquid is expressed by thermodynamic properties such as exothermic enthalpy of mixing.[4] The above and the fact that the vapor pressure of Bi is much higher (3 orders of magnitude at \({T}_{\text{M}}\) of Cu) than the vapor pressure of Cu[5] makes experimental determination of the thermophysical properties, such as density, surface tension and viscosity, of the Bi–Cu liquid solutions particularly challenging. Recently, Bi–Cu alloys with high Bi content gained interest as potential material for thermal energy storage,[6] while alloys with low Bi content as liquid catalyst for methane pyrolysis.[7] The Bi–Cu alloys are constituent subsystems of some multicomponent alloys of technical importance, such as solders.[8] Considering very limited, or even lack of any, experimental data published for several multicomponent alloys,[9] several researchers moved to modeling using geometrical models, which rely on input data from binary subsystems.[10,11] Others, like Brillo et al.,[12] aimed their efforts on studying correlations between thermodynamic and thermophysical data, which would allow to model one datum if the others are known. Thermodynamic software packages, such as Pandat,[13] allow for convenient calculation of thermophysical properties of liquid alloys.

Bi–Cu phase diagram calculated in Pandat© using COST MP0602 database,[3] with calculated iso-surface tension lines based on present work

The literature on thermophysical properties of Bi–Cu solutions is limited. Gomez et al.[14] measured densities of five Bi–Cu alloys, between 10 and 90 at. pct Cu, up to at most 250 K above respective liquidus temperature by the Archimedean method. Chentsov et al.[15] used the sessile drop method (SD) to measure densities of five Bi–Cu alloys (20 to 85 at. pct Cu) over a broad range of temperatures, i.e., between the respective liquidus temperature and 1473 K. More recently, Oleksiak et al.[16] carried out density measurements of 10 Cu-rich alloys (76.7 to 99.7 at. pct Cu) with the same method at high temperature range, i.e., 1373 K to 1573 K. Based on their own density data,[14,15] calculated molar volume of alloys, Gomez et al.[14] found excess molar volume negative, and Chentsov et al.[15] found excess molar volume slightly positive. In addition to density, Chentsov et al.[15] and Oleksiak et al.[16] measured surface tension with the sessile drop method, and both found the surface tension decreasing linearly with temperature for all compositions. Hara et al.,[17] on the other hand, only determined surface tension of five Bi–Cu alloys close to (1 K to 5 K above) liquidus temperature with the same method. Recently, Palmer et al.[7] reported surface tension measured for six Bi–Cu alloys only at 1373 K with maximum bubble pressure method (MBP). Some binary alloys of metals with great difference of surface tension, for example, Ag–Pb,[18] Cu–Sn,[19] and Cu–In,[20] exhibit an increase of the surface tension with increasing temperature in the range of compositions from 0.5 to 0.9 mole fractions of the component of higher surface tension. This is explained by thermodynamics of respective systems and lower-surface tension components acting as a surface-active element and is in line with theoretical modeling.[21] In view of the above, the aim of this work is to (1) determine the density and surface tension of three Bi–Cu alloys containing 0.25, 0.5 and 0.75 mole fractions of Cu, respectively; (2) to model molar volume, density and surface tension and verify whether models agree with experimental data.

2 Experimental

Alloys were prepared by melting accurate amounts of pure Bi (99.999 pct) and Cu (99.999 pct) in graphite crucibles in a glovebox filled with high-purity (99.9999 pct) Ar atmosphere. No mass loss was observed in the course of alloy preparation. Density measurements were carried out with dilatometric method and surface tension measurements with maximum bubble pressure (MBP) method; schematic drawings of both methods are shown in an earlier paper[22] (Figures 2 and 1, respectively). For both density (\(\rho \)) (Eq. [1]) and surface tension (\(\sigma \)) measurements, low-porosity graphite crucibles were used. Density and surface tension measurements were carried out under Ar–15 pct H2 protective atmosphere. Before entering the measurement chamber the gas was first dehydrated by passing through a P2O5 bed; subsequently, traces of O2 were removed by passing through Ti shavings heated to 1173 K. The MBP method surface tension measurements take time; to suppress the risk of change in alloy composition with time due to Bi vapor pressure,[5] measurements were started from lower temperature, and each charge of alloy was used for 2-3 consecutive temperature steps. For instance, in the case of equimolar Bi–Cu alloy, four separate charges were used for measurement.

The basis of the dilatometric method is to measure the volume of a known mass of a liquid. In the present setup,[22] a charge of a metal or alloy of known mass (\(m\)) is placed in a cylindrical crucible of known internal diameter (\(D\)). Once the liquid charge attains thermal equilibrium at the desired temperature, the height (H) of liquid in the crucible is measured by lowering a molybdenum rod with a micrometer screw along the crucible’s axis of symmetry. Both the crucible and the rod are connected to an ohmmeter, and a short circuit indicates the moment the rod touches the free surface of liquid. Because measurements were conducted at high temperatures, thermal expansion of graphite and molybdenum was considered. Assuming graphite is not wet by liquid metals therefore, as schematically drawn in Figure 2, due to surface tension, the free surface of a liquid forms a convex meniscus. For the same reason, there is a void at the bottom of the crucible. If not accounted for, these would lead to falsely high volume; therefore, the “empty” volume due to surface tension effect \({V}_{\sigma }\) has to be detracted from the volume of the cylinder of a known \(D\) and \(H\) (i.e., \(\pi {\left(D/2\right)}^{2}H\)), as shown in Eq. [2]. The \({V}_{\sigma }\) can be calculated if the radii \({r}_{1}\) and \({r}_{2}\) are estimated. At set temperature, once thermal equilibrium is reached, the pressure exerted by the liquid on the bottom of the crucible (\(\rho gH\)) is equaled by the capillary pressure (\(2\sigma /{r}_{1}\)), which lets us assume that \({r}_{1}=2\sigma /\rho gH\). On the free surface, a force of surface tension (\(2\pi \sigma {r}_{2}\)), which tends to make the surface spherical, is counterbalanced by the weight of the liquid (\(\frac{4}{3}\pi {r}_{2}^{3}\rho g)\), which lets us assume that \({r}_{2}={\left(3\sigma /2\rho g\right)}^{0.5}\). Reference \(\rho \) and \(\sigma \) of pure metals were used for first estimation of \({r}_{1}\) and \({r}_{2}\); next both \(\text{radii}\) were corrected using the measured \(\rho \) and \(\sigma \), and later used as a first estimate for alloys. The \({V}_{\sigma }\) is a sum of volumes \({V}_{r}\) (Eq. [3]) of two rotational figures (in Eq. [3] \(r\) stands for \({r}_{1}\) or \({r}_{2}\)), which are created by rotating a two-dimensional figure (at the free surface represented by white area schematically shown in the upper-right corner of Figure 2) about the crucible axis of symmetry. The value of \({V}_{\sigma }\) depends on the studied liquid (it’s \(\rho \) and \(\sigma \)) and temperature, whereas its share in the total volume depends on crucible diameter \(D\) and height of liquid \(H\). In the present case \({V}_{\sigma }\) was between 0.2 and 0.5 pct of the total volume \(V\) and was accounted for in Eq. [2].

Given that the mass (\(m\)) was measured with 0.0001 g uncertainty, while crucible diameter (\(D\)) and height of liquid (\(H\)) with uncertainty of 0.01 mm, the systematic error of the present dilatometric method did not exceed 0.3 pct.

The MBP method, despite its simplicity, is one of most accurate methods for surface tension measurements of liquid metals in a broad temperature range. Its great advantage is that successive measurements are made on a freshly formed surface.[23] In MBP method inert gas is blown through a capillary immersed in liquid metal. Maximum pressure (\({P}_{\text{max}}\)) needed for a gas bubble to detach from a capillary tip is measured, and this pressure is proportional to the liquid’s surface tension. The exact surface tension value is determined according to Sugden.[24] For surface tension measurement molybdenum capillaries were used. Surface tension is calculated according to Eq. [4], where: \(r\) = capillary radius, \(g\) = standard acceleration due to gravity, and \({h}_{\text{C}}\) = depth of capillary immersion.

Determination of immersion depth of capillary (\({h}_{\text{C}}\)) is the greatest source of error in the MBP method, especially concerning random error. Because of this it is important to detect the moment the capillary tip touches the free surface of liquid, and it is done in the same way as in the case of dilatometric measurements. The \({h}_{\text{C}}\) was measured with a micrometer screw with uncertainty of 0.01 mm. Radius of the capillary tip was measured with optical microscope with uncertainty of 0.001 mm. The uncertainty of \({P}_{\text{max}}\) measured with differential pressure gauge was 1 Pa. Overall systematic error of the present MBP method was, depending on composition and temperature, 1 to 2 pct. This in line with ± 2 pct systematic error of different methods quoted in Reference 30.

3 Modeling of the Surface Tension

Surface tension measurements of liquid metals are time consuming and costly. Interest in multi-component alloys increases the effort needed substantially. Thus, several models of thermo-physical properties, such as surface tension and viscosity, were developed to calculate these properties based on thermodynamic data of alloys and thermo-physical properties of pure constituents. One of the earliest models bonding the surface tension of alloys with molar surface areas of components and their activities in liquid phase is the Butler equation,[25] later modified by Yeum et al.[26] and Tanaka et al.[27] We used this model to calculate surface tension and surface composition of Bi–Cu alloys.

Assuming equilibrium between the bulk phase of a binary alloy and its surface layer, which is treated as a separate ‘‘phase,’’ the surface tension of the binary alloy can be described as Eq. [5].

where \(R\), \(T\), \({\sigma }_{i}\), \({A}_{i}\), \({x}_{i}\), \({x}_{i}^{\text{(s)}}\) are the universal gas constant, absolute temperature, surface tension of component \(i\), molar surface area of component \(i\), mole fraction of component \(i\) in the bulk and mole fraction of component \(i\) in the surface layer, respectively. The surface area \({A}_{i}\) is calculated from Avogadro’s number \({N}_{0}\), the atomic mass \({M}_{i}\) and density data \({\rho }_{i}\), as follows:

This method of surface tension calculation was developed for the first time by Butler[25] under the assumption that the difference in composition between the surface ”phase” and the bulk phase is restricted to the first layer of molecules. The partial excess Gibbs energy of the component \(i\) in the bulk can be expressed in the form of Redlich-Kister polynomials[28]:

where \({L}_{i-j}^{v}\) are the parameters dependent on temperature. There is an assumption that the absolute value of partial excess Gibbs energy of a component in the surface layer (\({G}_{i}^{\text{Ex}(s)}\)) is smaller than that in the bulk phase \({G}_{i}^{\text{Ex}}\) because atoms in the surface layer have lower coordination numbers than those in the bulk phase.

where \(\beta \) is an adjustable parameter. Some authors assume that the adjustable parameter is equal to the ratio of the coordination number of the surface atoms to the coordination number of the atoms in the bulk phase. Following Tanaka et al.,[27] we take \(\beta \) = 0.83. It should be noted though that this parameter’s value does not significantly affect the calculated surface tension.[21]

In this work, we used the CALPHAD approach and Pandat software, described elsewhere,[13] to model density and the surface tension of Bi–Cu alloys. The Gibbs energy functions for pure components were taken from SGTE Unary Database.[29] Binary parameters for Bi–Cu alloys were taken from the COST MP0602 thermodynamic database.[3] The molar volumes of pure liquid components are from present density results, whereas excess molar volume of liquid Bi–Cu alloys was worked out in the present work (Eq. [12]). Surface tension of Bi, Cu was taken from recommended data of Mills and Su.[30]

4 Results and Discussion

4.1 Density and Molar Volume

The results of density measured for pure Bi, Cu and Bi–Cu alloys are shown in Figure 3. For all the compositions, density decreases linearly with temperature. The data in Figure 3 were treated with linear regression fit, and the resulting equations are gathered in Table I. Based on the standard deviation of densities calculated from linear regression in Table I, random error can be estimated, and it does not exceed 0.4 pct. Systematic and random errors combined give overall dilatometric density measurement uncertainty of 0.7 pct. This uncertainty appears higher than uncertainties of 0.05 to 0.4 pct quoted in the literature[31,32] for the Archimedean (Arch.) method and is close to the uncertainty quoted for sessile drop (SD) method, but often uncertainties in the literature only express random errors (standard deviation of experimental data) with systematic errors not being discussed.

Density dependence on temperature for Bi–Cu alloys. Points = present results; solid lines = linear fit to experimental data from Table I

For comparison, in Figure 4(a) present results of Bi are shown with recommended density data,[31] as well as densities from References 14 and 15. It must be explained that in Reference 14 they did not report measurements of the density of pure Bi or cite specific literature references. Since they[14] reported ideal molar volumes of four Bi–Cu alloys at six temperatures in a table, we were able to reverse calculate the density of pure Bi. This turned out to be nearly the same as the one reported in an earlier paper[33] from the same group of authors, as well as very close to the recommended density data.[31] The latter[31] are on average 0.7 pct lower than the present results, while those determined with SD method[15] are on average 0.9 pct higher than the present results. Error bars imposed on the present results represent the 0.7 pct uncertainty of dilatometric density measurement. Assael et al.[31] worked out their recommended density data by means of linear regression analysis of data published by others. In the case of pure Bi, they[31] considered 11 data sets from the literature, which, despite being measured with different methods on Bi of varying purity, are fairly consistent. This is expressed by rather low 0.6 pct standard deviation of density calculated (dashed line) from linear regression of literature data.[31] In Figure 4(b) present density results of Cu are compared with recommended[32] as well as experimentally determined densities.[14,15] Incidentally, the density of Cu measured by Gomez et al.[14] by the Archimedean method, with uncertainty of 0.06 pct, is nearly identical to the present results. The SD method results of Chenstsov et al.[15] are lower and recommended densities[32] are higher than the present results, but both appear to lie within 0.7 pct margin of uncertainty of the present results. Assael et al.[32] took eight literature data sets into linear regression analysis (data set from Reference 14 was not among them), and the standard deviation of calculated density (dashed line) was 1.3 pct. Earlier, Gomez et al.[14] only graphically compared their results in the range 1356 K to 1523 K with ten preceding references (of which five were later cited in Reference 32) and showed that the literature Cu density data not only differ at \({T}_{\text{M}}\) but some also significantly differ with respect to the dependence on temperature \({\text{d}}\sigma/{\text{d}}T\). Clearly, literature density data of Cu are less consistent than the density data of Bi. That the Cu density measurements are conducted at temperatures 800 K higher than typical measurement range of the Bi density provides some explanation for the discrepancy observed. On a more general note, reference-recommended data derived from linear regression analysis of published density data are no better than the experimental data they are based on.

Using the densities \({\rho }_{{{i}}{-}{{j}}}\) of Bi–Cu alloys molar volume \({V}_{{{i}}{-}{{j}}}\) can be calculated according to Eq. [9], where \({x}_{{{i}}}\), \({x}_{{{j}}}\) are respective mole fractions and \({M}_{{{i}}}\), \({M}_{{{j}}}\) are respective atomic masses. Excess molar volume \({V}_{{{i}}{-}{{j}}}^{\text{Ex}}\) (Eq. [10]) is a measure of molar volume deviation from ideal (additive) molar volume \({V}_{{{i}}{-}{{j}}}^{{\text{Id}}}\). In Figure 5 molar volume calculated at 1373 K with Eq. [9] is shown together with relevant literature data. Clearly, molar volumes of Bi–Cu calculated based on present density results show positive (positive \({V}^{\text{Ex}}\)) deviation from ideal. This is the opposite to the molar volumes based on Gomez et al.’s[14] density data, which show negative \({V}^{\text{Ex}}\), although it should be noted that in both data sets the \({V}^{\text{Ex}}\) is relatively small. Data based on both Chentsov et al.[15] and Oleksiak et al.[16] seem to follow a nearly additive trend. To simplify, positive \({V}^{\text{Ex}}\) value indicates repulsive interactions between dissimilar atoms, meaning that an alloy showing positive volume changes on mixing has stronger self-interaction energies than mutual-interaction energies; therefore, excess thermodynamic properties such as enthalpy of mixing are expected to show positive values.[23] Although no strong correlation between the sign of enthalpy of mixing \({H}_{\text{mix}}\) and excess molar volume \({V}^{\text{Ex}}\) exists,[23] alloys with a miscibility gap show both positive \({H}_{\text{mix}}\) and \({V}^{\text{Ex}}\). Similarly, considering excess Gibbs free energy, alloys with positive excess Gibbs energy tend to have slightly positive excess molar volume, while alloys with strong negative excess Gibbs free energy show negative excess molar volume.[9] Nomsi Nzali and Hoyer[34] examined eleven Bi–Cu liquid alloys with x-ray diffraction and confirmed that there is indeed a segregation tendency in the Bi–Cu melts with a maximum around 50 at. pct of Cu. This and positive enthalpy of mixing of Bi–Cu alloys[4] (with maximum of ≥ 5 kJ mol−1 near 50 at. pct of Cu) convince us that liquid Bi–Cu should show positive \({V}^{\text{Ex}}\).

Since the atomic radius of Bi (160 pm) is greater than the atomic radius of Cu (135 pm), one could argue that negative \({V}^{\text{Ex}}\) is possible. Assuming that liquid alloy is a random mixture of hard spheres, then adding smaller spheres (atoms) to larger ones would increase the total volume of solution less than adding same-size spheres. As a result, the molar volume would be smaller than additive (i.e., excess molar volume would have negative sign). However, internal structure of a melt is determined by interatomic interactions. Concentration-concentration fluctuation function \({S}_{CC}\left(0\right)\)[35] is useful in understanding the structure of a melt and binding of atoms at microscopic level.[36] It can be derived (Eq. [11]) from activities of components \({a}_{{\text{Bi}}}\), \({a}_{{\text{Cu}}}\).[3] In the case of ideal mixing concentration-concentration fluctuation function \({S}_{CC}\left(0,id\right)\) is a product of component concentrations. In the case of alloys which form intermetallics in the solid, such as Al–Cu,[36] \({S}_{CC}\left(0\right)\) is smaller than \({S}_{CC}\left(0,id\right)\). However, in the case of alloys with a demixing tendency (such as the present case), the \({S}_{CC}\left(0\right)\) has a single maximum and is greater than \({S}_{CC}\left(0,id\right)\), as shown in Figure 6, indicating that Bi-Bi and Cu–Cu bonds are stronger than Bi–Cu bonds. As a result, a single Bi atom tends to have other Bi atoms as its nearest neighbors (the same applies to Cu atoms) meaning that atoms are not randomly mixed and the effect of different atomic sizes is effectively canceled.

Excess molar volume dependence on temperature and concentration, as any excess property, can be described with the Redlich–Kister (R–K)[28] polynomial (Eq. 12), where \({}^{k}{A}_{i-j}\) are temperature-dependent parameters (for \(k\) = 0, 1, 2, …). Based on the present results, the following were worked out: \({}^{0}A\) = 2.376761+0.00011T; \({}^{1}A\) = –0.452951+0.000749T; \({}^{2}A\) = –6.512578+0.005722T.

Figure 7 shows the calculated enthalpy of mixing[4] and excess molar volume (Eq. [12]) dependence on composition of liquid and metastable liquid Bi–Cu alloys at 1273 K. It is notable that maxima of curves are off the equimolar point. According to Kleppa[37] excess molar volume contributes to the enthalpy of mixing and, although small, this contribution \(\Delta H\) can be approximated with Eq. [13], where \(\alpha \) is the coefficient of thermal expansion and \({\kappa }_{\text{T}}\) is the isothermal compressibility. \(\alpha \) can readily be derived from density data at any composition (Eq. [14]), whereas to calculate \({\kappa }_{\text{T}}\) density and speed of sound in liquid at a specific composition are needed; the latter are not available for Bi–Cu alloys. For simplicity’s sake, \({\kappa }_{\text{T}}\) of binary alloy can be calculated assuming additivity (\({\kappa }_{\text{T}}=\sum {x}_{i}{\kappa }_{T,i}\)) of \({\kappa }_{T,i}\) of pure Bi, Cu.[38] Using the density of x(Cu) = 0.5 alloy (Table I), present \({V}^{\text{Ex}}\) (Eq. [12]), \({\kappa }_{T,Bi}\)= 0.0124 GPa-1 and \({\kappa }_{T,{\text{Cu}}}\) = 0.0644 GPa-1 at 1273 K,[36] we calculated \(\Delta H\). The resulting \(\Delta H\) = 3.7 J/mol, i.e., < 0.1 pct of the \({H}_{\text{mix}}\) = 5.2 kJ/mol at x(Cu) = 0.5, meaning the effect of excess molar volume on mixing enthalpy of liquid Bi–Cu alloys is negligible.

In their recent publication, Brillo et al.,[12] based on analysis of excess Gibbs free energy and molar volumes for over 20 binary systems, proposed a revised Eq. [15], which bonds excess Gibbs free energy (\({G}^{\text{Ex}}\)) and isothermal compressibility (\({\kappa }_{\text{T}}\)) with excess molar volume (\({V}^{\text{Ex}})\). We used Eq. [15] to calculate \({V}^{\text{Ex}}\) of liquid Bi–Cu alloy of equimolar composition (\({x}_{{\text{Bi}}}\)= \({x}_{{\text{Cu}}}\)= 0.5) over 1073 K to 1773 K temperature range, with \({G}^{\text{Ex}}\) calculated from Reference 3 and \({\kappa }_{\text{T}}\) calculated from the data of pure components[38] as explained above. The resulting calculated \({V}^{\text{Ex}}\) is shown as a function of \({G}^{\text{Ex}}\) (solid line). Both \({G}^{\text{Ex}}\) and \({V}^{\text{Ex}}\) have positive values. Note that in the case of studied liquid alloy \({G}^{\text{Ex}}\) decreases with increasing temperature. Therefore, we can say that the value of \({V}^{\text{Ex}}\) calculated with Eq. [15] slightly increases with increasing \({G}^{\text{Ex}}\), meaning that \({V}^{\text{Ex}}\) decreases with increasing temperature. For comparison purposes, \({V}^{\text{Ex}}\) worked out based on our measured data (Eq. [12]) is shown as a dotted line in Figure 8. This appears to slightly decrease with increasing \({G}^{\text{Ex}}\) (i.e., increases with increasing temperature). Even though the \({V}^{\text{Ex}}\) of equimolar alloy calculated with Eq. [15] appears approximately 30 pct lower than \({V}^{\text{Ex}}\) determined from experimental data (Eq. [12]) in the considered temperature range (1073 K to 1773 K), it should be noted that agreement between the model[12] and experiment is reasonably good.

Figure 9 illustrates the density of Bi–Cu alloys obtained by different methods and different authors.[14,15,16] These measured data are compared with densities calculated assuming ideal molar volume (dashed line) as well as densities calculated utilizing positive excess molar volume (solid line) determined in this work. Clearly, the present experimental data are very well reproduced.

4.2 Surface Tension

The results of present surface tension measurements are shown in Figure 10. Surface tension of alloy containing 0.25 mole fraction of Cu decreases and that of 0.5 mole fraction of Cu appears to be almost independent of temperature in the studied temperature range, whereas surface tension of alloy containing 0.75 mole fraction Cu increases with temperature. This is the opposite tendency to the results of References 15 and 16 but it is in line with thermodynamic modeling as shown below. From iso-surface tension lines shown in Figure 1, it stems that the change of sign of surface tension temperature coefficient occurs for alloys with approximately 50 at. pct Cu. Near the 50 at. pct Cu also maxima of the enthalpy of mixing and excess molar volume occur, as discussed above. Having this in mind, it can be assumed that thermodynamic properties of liquid Bi–Cu alloys are mainly responsible for the observed surface tension dependence on temperature.

In Figure 10 dotted lines represent reference surface tension of Bi and Cu.[30] Mills and Su[30] designed their work as an update to the fundamental review of Keene[39] who, based on 17 literature references for Bi and 30 references for Cu, calculated average equations describing temperature dependences of both metals. In the case of Bi, the average from Reference 39 was adopted in Reference 30 while in the case of Cu a new average, yielding lower values than the average in Reference 39, was calculated based on the seven references cited in Reference 30 and the references cited in Reference 39. Mills and Su[30] pointed out that the values calculated with their equation for Cu are subject to ~30 mN m−1 uncertainty. No estimates of uncertainty were made in Reference 39, but standard deviations of the cited data at \({T}_{\text{M}}\) are: 10.5 mN m−1 (2.8 pct of the average at \({T}_{\text{M}}\)) for Bi and 41 mN m−1 (3.1 pct of the average at \({T}_{\text{M}}\)) for Cu. Our present results for Cu are close to reference data,[30] and only 35 mN m−1 (i.e., 2.7 pct) lower at 1373 K, with the difference decreasing with temperature, which is very little difference considering high temperature measurements. We did not measure surface tension of liquid Bi in this work since it was measured with the exact same setup before,[40] and the results were generally close to the reference data. The present results (represented by points in Figure 10) were fitted with linear equations, and the resulting parameters were gathered in Table II. Utilizing the standard deviation of surface tension calculated from linear regression in Table II, random error was estimated, and it is lower than 1.4 pct. Systematic and random errors combined lead to an overall MBP measured surface tension uncertainty of 3.4 pct. The individual surface tension data appear more scattered than the densities. Though it should be noted that such scattering in the case of surface tension measurements is not uncommon and is not a method specific feature. For example, standard deviation from linear fit in our 0.75 mole fraction Cu alloy is 6.2 mN m−1, and it is similar in the case of data from sessile drop method. For example, it is 7.4 mN m−1 for \({x}_{{\text{Cu}}}\) = 0.7[15] and 6.7 mN m−1 in the case of \({x}_{{\text{Cu}}}\) = 0.767.[16] Both Chentsov et al.[15] and Oleksiak et al.[16] used sessile drop method, which is characterized by relatively large surface area with respect to volume of a sample, in contrast to MBP method, making it sensible to evaporation induced mass loss and resulting composition change during measurement. The experimental conditions in Reference 15 are limited to He protective atmosphere. There is little more information in Reference 16: they used Ar protective gas and alumina substrates. The reported contact angle[16] of Bi–Cu alloys on Al2O3 (> 130 deg for all the alloys except for \({x}_{{\text{Cu}}}\) = 0.767 and 0.831 for which it decreases with increasing temperature from 125 to 116 deg) is large indicating non-wetting and possibly no reaction between Bi–Cu alloy and alumina substrate.

Using the Butler model (Eq. [5]), we calculated surface tension dependence on temperature for three alloys (\({x}_{{\text{Cu}}}\) = 0.25; 0.5; 0.75), and the results are depicted as dashed lines in Figure 10. While the calculated surface tension of \({x}_{{\text{Cu}}}\) = 0.25 alloy decreases and surface tension of \({x}_{{\text{Cu}}}\) = 0.75 increases with increasing temperature, the surface tension of \({x}_{{\text{Cu}}}\) = 0.5 alloy does not change with temperature. In fact, calculations of surface tension dependence on concentration for liquid and metastable liquid Bi–Cu at several temperatures (between 773 and 1373 K) indicate that for alloys with \({x}_{{\text{Cu}}}\) < 0.5 surface tension slope is negative (\({\text{d}}\sigma/{\text{d}}T\) < 0) and positive (\({\text{d}}\sigma/{\text{d}}T\) > 0) for \({x}_{{\text{Cu}}}\) > 0.5. Temperature coefficient of an alloy surface tension (\({\text{d}}\sigma/{\text{d}}T\)) was studied theoretically by many, for example[18,41,42]; an interested reader is sent to a recent comprehensive review of Santos and Reis.[21] Santos and Reis,[21] using Eq. [5] for the case of an ideal solution (the third term on right side of Eq. [5] is omitted) of metals A and B (\({\sigma }_{\text{A}}> {\sigma }_{\text{B}}\)), and introducing \({S}_{\text{A}}\), i.e., surface area fraction of component A (Eq. [16]) (\({S}_{\text{A}}+{S}_{\text{B}}=1\)), worked out Eq. [17], allowing to calculate \({\text{d}}\sigma/{\text{d}}T\) for fixed bulk composition.

We used Eq. [17] to calculate temperature coefficients of Bi–Cu alloys (\({x}_{{\text{Cu}}}\) = 0.25, 0.5, 0.75) and compared them with experimentally determined coefficients as well as coefficients calculated for real solutions with Eq. [5]. Since the surface tension calculated from models does not change linearly with temperature, temperature coefficients were calculated at 100 K interval (Table III). In the case of copper-rich composition (\({x}_{{\text{Cu}}}\) = 0.75), both experimental and calculated temperature coefficients have positive signs, although it should be noted the coefficients calculated with Eq. [5] are greater than the ones calculated with Eq. [17]. The calculated temperature coefficients decrease with increasing temperature, and thanks to this we can calculate the temperature at which \({\text{d}}\sigma/{\text{d}}T\) changes sign to negative (surface tension reaches its maximum), which is 1644 K based on Eq. [17] and 2106 K based on Eq. [5]. In the case of equimolar composition (\({x}_{{\text{Cu}}}\) = 0.5) the experimental temperature coefficient is positive and close to zero, while the calculations with Eq. [17] indicate negative temperature coefficients. In contrast, surface tension calculated with Eq. [5] has positive temperature coefficients in the studied temperature range, which are of similar magnitude to the experimental one, as can be seen in Figure 9. The surface tension calculated with Eq. [5] for \({x}_{{\text{Cu}}}\) = 0.5 alloy reaches its maximum at 1505 K and decreases above this. Finally, in the case of \({x}_{{\text{Cu}}}\) = 0.25 alloy, whereas experimental temperature coefficient is negative but close to zero, calculated temperature coefficients are clearly negative in the examined temperature range. Despite the difference in temperature coefficient value, it is notable (Figure 10) that the difference between the experimental surface tension and surface tension calculated with the Butler model is even smaller for this composition than for the other two. Table III contains the concentration of Bi in the surface layer \({x}_{{\text{Bi}}}^{(s)}\) and surface area fraction of Cu \({S}_{{\text{Cu}}}\) calculated with Eq. [17] in the temperature range corresponding to the experimental one, whereas Figure 10 shows \({x}_{{\text{Bi}}}^{(s)}\) calculated with Eq. [17] for a much broader temperature range (1100 K to 2100 K). Regardless of the bulk composition, the surface layer is strongly enriched in Bi, for example, at 1250 K \({x}_{{\text{Bi}}}^{(s)}\)= 0.96 for \({x}_{{\text{Cu}}}\) = 0.75 alloy and \({x}_{{\text{Bi}}}^{(s)}\)= 0.99 for \({x}_{{\text{Cu}}}\) = 0.25 alloy. Increase of temperature, as shown in Figure 10, decreases \({x}_{{\text{Bi}}}^{(s)}\) only slightly in the case of \({x}_{{\text{Cu}}}\) = 0.25 alloy, but the effect of temperature is more pronounced in the case of alloys with higher Cu content. This decrease in “surface excess” of Bi with increasing temperature is in accord with the demixing tendency decreasing with temperature, i.e., the decreasing difference among A–A, B–B and A–B atom pair interactions.

Figure 12 presents surface tension calculated at 1373 K over the whole concentration range according to the Butler model (Eq. [5]), which is represented by the solid line. The overall agreement between the experimental data and modeled values is good. The exception are data of Palmer et al.,[7] which are not only significantly lower than the calculated values but also lower than all the other experimental data. In Figure 12, it is striking that minute additions of Bi to liquid Cu drastically reduce its surface tension because of the Bi surface active role. Already at \({x}_{{\text{Cu}}}\) = 0.85, the surface tension is ~ 400 mN m−1, much lower than the surface tension of Cu and not much higher than the surface tension of pure Bi. This is due to enrichment of the surface layer in Bi (Table III, Figure 11) ,while the concentration of Cu in the surface layer is several orders of magnitude lower than in the bulk of Bi–Cu alloy. From Figure 11, it stems that in the whole concentration range the excess surface concentration of Bi is decreased with increasing temperature. This tendency is much stronger for Cu-rich alloys, meaning that for these alloys concentration of Cu (i.e., higher surface tension component) in the surface increases with temperature at a greater rate, which adds to the explanation for positive surface tension temperature coefficients. In turn, composition of the surface layer results from thermodynamic equilibrium between the bulk and surface phase.

Concentration of Bi in the surface layer of Bi–Cu alloys’ dependence on temperature, calculated with Eq. [17] for bulk compositions \({x}_{\text{Bi}}\) = 0.25, 0.50, 0.75

Present results in Figure 12 are the least deviated from calculated values, whereas for some compositions[15,16] the difference is greater. For comparison, dashed line in Figure 12 represents values calculated with Butler model assuming liquid Bi–Cu has thermodynamic properties of ideal solution (\({G}_{i}^{\text{Ex}}\) = 0). Although the overall trend is correct, this model fails to reproduce the experimental data well. This is an indication that the ideal solution model is too much of a simplification in the case of Bi–Cu solutions. Surface tension of binary alloys is not a linear function of composition but generally has a concave shape; this is due to enrichment of the surface layer with components having lower surface tension. Eberhart[43] assumed that surface tension of a binary mixture is a linear function of surface composition (Eq. [18]). Under the condition of thermodynamic equilibrium, i.e., excess Gibbs free energy of component \(i\) in the surface layer equal to that in the bulk (\({G}_{i}^{Ex(s)}={G}_{i}^{\text{Ex}}\)), a separation factor \(\chi \) could be defined (Eq. [19]), which expresses surface enrichment in the component of lower surface tension. Assuming the surface-active component is component 1, then \(\chi \) > 1 indicates surface enrichment in this component. By combining Eqs. [18] and [19], we have Eq. [20]. Eberhart[43] notes that Eq. [20] works well for binary alloys whose components have similar properties (specifically: similar surface tension) and fails for others. Bi, Cu being the latter case, Eq. [20] (dotted line in Figure 12) significantly deviates from the values calculated according to Eq. [4] and fails to reproduce the experimental data in the range 0.6 < \({x}_{{\text{Cu}}}\)< 1.

Surface tension of Bi–Cu alloys at 1373 K. Points represent: circles = present data from equations in Table II; squares[15]; triangles,[16] diamonds.[7] Solid line represents surface tension calculated according to Butler model for real solution; dashed line = Butler model for ideal solution; dotted line = Eberhart model

5 Conclusion

Using the dilatometric and MBP methods, the density and surface tension of liquid Bi–Cu solutions were measured. Present results were confronted with literature data and theoretical models. Density of studied alloys decreases linearly with increasing temperature. Based on the present density results and thermodynamic calculations, it may be concluded that liquid Bi–Cu alloys exhibit positive excess molar volume. Comparison of mixing enthalpy with excess molar volume revealed that maxima of both occur near the equimolar concentration. A recent model proposed by Brillo reasonably well predicts excess molar volume from excess Gibbs free energy data. Surface tension dependence on temperature determined experimentally is linear, and the one from model calculations is near linear in the experimental temperature range. It was found that for equimolar alloy surface tension does not depend on temperature, whereas for copper reach alloy surface tension increases with temperature in the studied temperature range. The above discussion confirms that thermodynamic properties of liquid Bi–Cu alloy are predominantly responsible for the observed surface tension temperature coefficients. In the whole concentration range, present surface tension experimental results are best reproduced by Butler model calculations for real solution, whereas calculations assuming ideal behavior of Bi–Cu solutions diverge from experimental data. Butler model for real solutions is also more accurate with respect to the surface tension temperature coefficient (Table III) compared to the model of Santos and Reiss derived from Butler model for ideal solutions.

References

O. Teppo, J. Niemela, and P. Taskinen: Thermochim. Acta., 1990, vol. 173, pp. 137–50.

L.S. Chang, B. Straumal, E. Rabkin, W. Gust, and F. Sommer: J. Phase Equilib., 1997, vol. 18, pp. 128–35.

A. Kroupa, A. Dinsdale, A. Watson, J. Vřešťál, A. Zemanova, and P. Broz: J. Min. Metall. B., 2012, vol. 48, pp. 339–46.

H. Flandorfer, A. Sabbar, C. Luef, M. Rechchach, and H. Ipser: Thermochim. Acta., 2008, vol. 472, pp. 1–10.

A. Zajaczkowski, J. Czarnecki, and A. Suruło: Calphad., 2016, vol. 52, pp. 66–77.

S.P. Singh, B.K. Deb Barman, and P. Kumar: Mater. Sci. Eng. A., 2016, vol. 677, pp. 140–52.

C. Palmer, M. Tarazkar, H.H. Kristoffersen, J. Gelianas, M.J. Gordon, E.W. McFarland, and H. Metiu: ACS Catal., 2019, vol. 9, pp. 8337–45.

Z. Moser, W. Gasior, K. Bukat, J. Pstrus, R. Kisiel, J. Sitek, K. Ishida, and I. Ohnum: J. Phase Equilib. Diff., 2006, vol. 27, pp. 133–39.

J. Brillo: Thermophysical Properties of Multicomponent Liquid Alloys, DeGruyter, Berlin, 2016.

M. Wu and X. Su: J. Mater. Sci. Mater. Electron., 2015, vol. 26, pp. 8425–31.

R. M’chaar, A. Sabbar, M. el Moudane, and N. Ouerfelli: Philos. Mag., 2020, vol. 100, pp. 1415–38.

J. Brillo, M. Watanabe, and H. Fukuyama: J. Mol. Liq., 2021, vol. 326, p. 114395.

W. Cao, S.-L. Chen, F. Zhang, K. Wu, Y. Yang, Y.A. Chang, R. Schmid-Fetzer, and W.A. Oates: Calphad., 2009, vol. 33, pp. 328–42.

M. Gomez, L. Martin-garin, H. Ebert, P. Bedon, and P. Desre: Z. Metallkde., 1976, vol. 67, pp. 131–34. (in German).

V.P. Chentsov, N.V. Belousova, E.A. Pastukhov, L.I. Serebryakova, and L.T. Antonova: Rasplavy., 2000, vol. 6, pp. 3–6. (in Russian).

B. Oleksiak, J. Labaj, J. Wieczorek, A. Blacha-Grzechnik, and R. Burdzik: Arch. Metall. Mater., 2014, vol. 59, pp. 281–85.

S. Hara, M. Kanao, and K. Ogino: J. Jpn. Inst. Met., 1993, vol. 57, pp. 164–69. (in Japanese).

P. Terzieff: J. Alloy Compd., 2008, vol. 458, pp. 302–06.

S. Amore, E. Ricci, T. Lanata, and R. Novakovic: J. Alloy Compd., 2008, vol. 452, pp. 161–66.

M. Kucharski, P. Fima, P. Skrzyniarz, and W. Przebinda-Stefanowa: Arch. Metall. Mater., 2006, vol. 51, pp. 389–97.

M.S.C.S. Santos and J.C.R. Reis: J. Alloy Compd., 2021, vol. 864, p. 158839.

W. Gasior, Z. Moser, and J. Pstrus: J. Phase Equilib., 2003, vol. 24, pp. 504–10.

T. Iida and R.I.L. Guthrie: The Physical Properties of Liquid Metals, Calderon Press, Oxford, 1993, pp. 68–69.

S. Sugden: J. Chem. Soc. Trans., 1922, vol. 121, pp. 858–66.

J.A.V. Butler: Proc. R. Soc. Lond. A., 1932, vol. 135, pp. 348–75.

K.S. Yeum, R. Speiser, and D.R. Poirier: Metall. Trans., 1989, vol. 20B, pp. 693–703.

T. Tanaka, K. Hack, T. Iida, and S. Hara: Z. Metallkde., 1996, vol. 87, pp. 380–89.

O. Redlich and A.T. Kister: Ind. Eng. Chem., 1948, vol. 40, pp. 345–48.

A.T. Dinsdale: Calphad., 1991, vol. 15, pp. 317–425.

K.C. Mills and Y.C. Su: Int Mater Rev., 2006, vol. 51, pp. 329–51.

M.J. Assael, A.E. Kalyva, K.E. Antoniadis, et al.: High Temp. High Pressures., 2012, vol. 41, pp. 161–84.

M.J. Assael, A.E. Kalyva, K.D. Antoniadis, et al.: J. Phys. Chem. Ref. Data., 2010, vol. 39, p. 033105.

L. Martin-Garin, P. Bedon, and P. Desre: J. Chim. Phys., 1973, vol. 70, pp. 112–18.

J. Nomssi Nzali and W. Hoyer: Z. Naturforsch., 2000, vol. 55a, pp. 381–89.

A.B. Bhatia and D.E. Thornton: Phys. Rev. B., 1970, vol. 2, pp. 3004–12.

M. Trybula, N. Jakse, W. Gasior, and A. Pasturel: Arch. Metall. Mater., 2015, vol. 60, pp. 649–55.

O.J. Kleppa: J. Phys. Chem., 1960, vol. 64, pp. 1542–46.

R.N. Singh, S. Arafin, and A.K. George: Physica B., 2007, vol. 387, pp. 344–51.

B.J. Keene: Int. Mater. Rev., 1993, vol. 38, pp. 157–92.

Z. Moser, W. Gąsior, and J. Pstruś: J. Phase. Equilib., 2001, vol. 22, pp. 1104–11.

I. Egry: Z. Metallkde., 2001, vol. 92, pp. 50–52.

J. Lee, W. Shimoda, and T. Tanaka: Meas. Sci. Technol., 2005, vol. 16, pp. 438–42.

J.G. Eberhart: J. Phys. Chem., 1966, vol. 70, pp. 1183–86.

Acknowledgment

The experimental part was conducted under the framework of COST Action MP0602.

Author Contribution

JP designed the study, did the experiments, helped with the literature review and manuscript revision, and checked the manuscript before submission. PF designed the study, did the calculations and the literature review, drafted and revised the manuscript.

Conflict of interest

The authors declare that they have no conflict of interests.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted September 1, 2021; accepted January 23, 2022.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Pstruś, J., Fima, P. Molar Volume and Surface Tension of Liquid Bi–Cu Alloys. Metall Mater Trans A 53, 1659–1673 (2022). https://doi.org/10.1007/s11661-022-06613-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-022-06613-5