Abstract

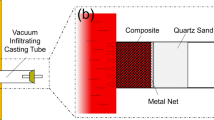

Laminated Cu–Pb–Sn/Steel composites (C/SC) with Pb-rich secondary phases (SPs) in different morphology were prepared by solid–liquid continuous casting compositing (S-LC). SPs transform from network to rod-like to abnormally coarsening morphology with casting temperatures increasing from 1473 K to 1513 K to 1533 K. The prepared C/SC possesses a high-quality interface and high bonding strength due to the existence of the Cu/Fe interdiffusion layer with a thickness of about 0.75 μm. The thickness calculated by CALPHAD is in the range of 0.38 to 1.35 μm which is consistent with experimental results. The mechanical properties of C/SC present a high correlation with the morphology of SPs. C/SC with network and rod-like SPs, respectively, shows the lowest and highest plasticity and carrying capacity. Finite element analysis (FEA) was conducted to simulate the plastic deformation of C/SC. By comparing the experiments with FEA results, the network SPs with high continuity were proven to significantly decrease the tensile strength and elongation of Cu–Pb–Sn alloy layer of C/SC by splitting the matrix. C/SC with rod-like SPs presents the highest mechanical performance due to the minimal damage to matrix.

Graphical Abstract

Similar content being viewed by others

References

B.W. Dong, J.C. Jie, S.H. Wang, Z.Z. Dong, and T.J. Li: Mater. Lett., 2020, vol. 262, p. 127174.

A.S. Sharma, N. Mishra, K. Biswas, and B. Basu: Wear., 2013, vol. 306, pp. 138–48.

V.T. Oksanen, A.J. Lehtovaara, and M.H. Kallio: Wear., 2017, vol. 388–389, pp. 72–80.

B.W. Dong, S.H. Wang, Z.Z. Dong, J.C. Jie, T.M. Wang, and T.J. Li: J. Mater. Sci. Technol., 2020, vol. 40, pp. 158–67.

H. Cui, J. Guo, Y. Su, H. Ding, W. Bi, X. Li, and H. Fu: Mater. Sci. Eng. A., 2007, vol. 448, pp. 49–55.

C. Dong and B. Wei: Scripta Mater., 1996, vol. 34, pp. 1523–28.

Y. Yang, D. Wang, J. Lin, D.F. Khan, G. Lin, and J. Ma: Mater. Des., 2015, vol. 85, pp. 635–39.

Y.J. Du, J.T. Xiong, F. Jin, S.W. Li, L. Yuan, D. Feng, J.M. Shi, and J.L. Li: Mater. Sci. Eng. A., 2021, vol. 802, p. 140610.

Z. Sun, H. Shao, X. Niu, and Y. Song: Mater. Sci. Eng. A., 2016, vol. 663, pp. 78–85.

B.W. Dong, J.C. Jie, X.X. Yao, S.C. Liu, Y.H. Chen, N. Zhong, and T.J. Li: J. Alloys Compd., 2019, vol. 791, pp. 936–46.

B.W. Dong, J.C. Jie, Z.Z. Dong, Y.H. Chen, N. Zhong, T.M. Wang, and T.J. Li: J. Mol. Liq., 2019, vol. 292, p. 111336.

B.K. Dhindaw, D.M. Stefanescu, A.K. Singh, and P.A. Curreri: Metall. Trans. A., 1988, vol. 19, pp. 2839–46.

C. Yu, L. Fu, H. Xiao, Q. Lv, and B. Gao: Mater. Sci. Eng. A., 2021, vol. 820, p. 141572.

P. Li, S. Wang, Y. Xia, X. Hao, and H. Dong: J. Mater. Sci. Technol., 2020, vol. 45, pp. 59–69.

M. Rao, G. Luo, J. Zhang, Y. Wang, Q. Shen, and L. Zhang: J. Mater. Sci. Technol., 2020, vol. 54, pp. 171–80.

H. Chen, H. Nie, W. Wang, J. Zhou, and R. Liu: J. Alloys Compd., 2019, vol. 806, pp. 1445–52.

H.S. Chen, W.X. Wang, H.H. Nie, J. Zhou, Y. Li, and P. Zhang: Vacuum., 2017, vol. 143, pp. 363–70.

J. Jie, C. Liu, S. Wang, B. Dong, S. Liu, and T. Li: Mater. Sci. Technol., 2019, vol. 35, pp. 1840–47.

J. Miettinen, P. Docheva, and G. Vassilev: CALPHAD., 2010, vol. 34, pp. 415–20.

C. Dai, H.H. Xu, S.Q. Wang, M. Yin, S.L. Cui, L.J. Zhang, Y. Du, and F. Zheng: CALPHAD., 2011, vol. 35, pp. 556–61.

S. Glasstone, K.J. Laidler, and H. Eyring: The Theory of Rate Processes, McGraw-Hill, New York, 1941.

Q. Wu, G. Xu, H. Chang, L. Zhou, and Y. Cui: CALPHAD., 2020, vol. 71, p. 102203.

X.J. Liu, N. Shangguan, and C.P. Wang: CALPHAD., 2011, vol. 35, pp. 155–59.

Y. Liu, L. Zhang, Y. Du, G. Sheng, J. Wang, and D. Liang: CALPHAD., 2011, vol. 35, pp. 376–83.

W.F. Gale and T.C. Totemeier: Smithells Metals Reference Book, Butterworth Heinemann, Oxford, 2003.

S. Fu, X. Chen, and P. Liu: Mater. Sci. Eng. A., 2020, vol. 771, p. 138656.

Z.L. Lin, Y.L. Li, M.H. Zhu, M.W. Li, Z.B. Yang, F.M. Wang, and Y.H. Sun: Nonferr. Met. Sci. Eng., 2015, vol. 006, pp. 37–41.

Acknowledgments

The authors gratefully acknowledge the supports of Talent Introduction Project of Hubei Polytechnic University (Nos. 21xjz15R, 19xjk18R); Open Fund Project of Hubei Key Laboratory of Intelligent Transportation Technology and Device, Hubei Polytechnic University, China (No. 2021XY102); The National Natural Science Foundation of China (Nos. 52071050, 51871041); and CompuTherm for providing the simulation tools.

Data Availability

The raw/processed data required to reproduce these findings cannot be shared at this time due to technical or time limitations.

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Dong, B., Jie, J., Peng, B. et al. Revealing the Relationship Between Morphology of Pb-Rich Secondary Phases and Mechanical Properties of Laminated Cu–Pb–Sn/Steel Composite Through CALPHAD and FEA. Metall Mater Trans A 53, 1462–1478 (2022). https://doi.org/10.1007/s11661-022-06609-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-022-06609-1