Abstract

Eutectics serve as an interesting material class for fundamental research on solidification as well as holding promise for new, high-tech applications. Thus, significant efforts have been made recently to understand the microstructure formation in ternary eutectics including Al–Ag2Al–Al2Cu, but mechanisms for microstructure evolution and pattern formation in these complex systems are not yet fully understood. This study focuses on the novel aspect of eutectic grain interaction by investigating mechanisms of grain growth competition at different heights in a directionally solidified sample by means of SEM, quantitative image analysis, and EBSD. An image analysis procedure was developed to visualize the microstructure alignment, allowing identification of individual eutectic grains and grain boundaries without large-scale EBSD analysis. This technique allowed for microstructural evolution to be tracked in individual grains as a function of growth height within a directionally solidified Al–Ag–Cu invariant ternary eutectic, demonstrating the pronounced defeat of less-ordered three-phase arrangements and indicating an energetic- or orientation-conditioned grain growth competition. Additionally, faceted interphase boundaries of Ag2Al were discovered and complex interactions depending on the crystallographic orientation at grain boundaries were analyzed, calling for revised models to evaluate microstructure formation in ternary eutectics.

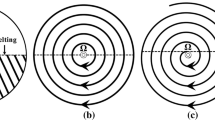

taken from 7 mm height

Similar content being viewed by others

References

D.A. Pawlak, S. Turczynski, M. Gajc, K. Kolodziejak, R. Diduszko, K. Rozniatowski, J. Smalc, and I. Vendik: Adv. Funct. Mater., 2010, vol. 20, pp. 1116–24.

D.A. Pawlak: Sci. Plena., 2008, vol. 4, p. 14801.

P. Steinmetz, A. Dennstedt, M. Şerefoğlu, I. Sargin, A. Genau, and U. Hecht: Acta Mater., 2018, vol. 157, pp. 96–105.

A. Dennstedt, M. Becker, P. Steinmetz, and L. Ratke: Microtomography of Directionally Solidified Ternary Eutectic Al–Ag–Cu Alloy (Experiment Report), 2015.

P. Steinmetz, J. Hötzer, A. Dennstedt, C. Serr, B. Nestler, and A. Genau: J. Cryst. Growth., 2018, vol. 498, pp. 230–43.

P. Steinmetz, S. Gadkari, and A. Genau: J. Cryst. Growth., 2019, vol. 507, pp. 425–36.

A. Genau and L. Ratke: Int. J. Mater. Res., 2012, vol. 103, pp. 469–75.

A.L. Genau and L. Ratke: IOP Conf. Ser. Mater. Sci. Eng., 2011, vol. 27, p. 012032.

J. Brillo, Y. Plevachuk, and I. Egry: J. Mater. Sci., 2010, vol. 45, pp. 5150–57.

A. Dennstedt and L. Ratke: Trans. Indian Inst. Met., 2012, vol. 65, pp. 777–82.

D. Du, Y. Fautrelle, Z. Ren, R. Moreau, and X. Li: Acta Mater., 2016, vol. 121, pp. 240–56.

S. Ebzeeva and L. Froyen: Trans. Indian Inst. Met., 2007, vol. 60, pp. 207–12.

F. Dai and B. Wei: Sci. China G., 2009, vol. 52, pp. 848–55.

U. Böyük, N. Maraşlı, E. Çadırlı, H. Kaya, and K. Keşlioǧlu: Curr. Appl. Phys., 2012, vol. 12, pp. 7–10.

U. Böyük, N. Maraşlı, H. Kaya, E. Çadırlı, and K. Keşlioǧlu: Appl. Phys. A., 2009, vol. 95, pp. 923–32.

P. Steinmetz, M. Kellner, J. Hötzer, A. Dennstedt, and B. Nestler: Comput. Mater. Sci., 2016, vol. 121, pp. 6–13.

P. Steinmetz, M. Kellner, J. Hötzer, and B. Nestler: Metall. Mater. Trans. B., 2018, vol. 49B, pp. 213–24.

P. Steinmetz, J. Hötzer, M. Kellner, A. Genau, and B. Nestler: Comput. Mater. Sci., 2018, vol. 148, pp. 131–40.

J. Hötzer, P. Steinmetz, M. Jainta, S. Schulz, M. Kellner, B. Nestler, A. Genau, A. Dennstedt, M. Bauer, H. Köstler, and U. Rüde: Acta Mater., 2016, vol. 106, pp. 249–59.

J. Hötzer, P. Steinmetz, A. Dennstedt, A. Genau, M. Kellner, I. Sargin, and B. Nestler: Acta Mater., 2017, vol. 136, pp. 335–46.

A. Choudhury: Trans. Indian Inst. Met., 2015, vol. 68, pp. 1–15.

M. Ruggiero and J. Rutter: Mater. Sci. Technol., 1997, vol. 13, pp. 5–11.

D. Lewis, S. Allen, M. Notis, and A. Scotch: J. Electron. Mater., 2002, vol. 31, pp. 161–67.

I. Sargin, A.L. Genau, and R.E. Napolitano: J. Phase Equilib. Diffus., 2016, vol. 37, pp. 75–85.

A. Dennstedt, A. Choudhury, L. Ratke, and B. Nestler: IOP Conf. Ser. Mater. Sci. Eng., 2016, vol. 117, p. 012025.

A. Dennstedt, L. Ratke, A. Choudhury, and B. Nestler: Metallogr. Microstruct. Anal., 2013, vol. 2, pp. 140–47.

I. Sargin and S.P. Beckman: Sci. Rep., 2019, vol. 9, pp. 1–8.

I. Sargin: Invariant and Univariant Eutectic Solidification in Ternary Alloys, PhD Dissertation, Iowa State University, 2015.

K.A. Jackson and J.D. Hunt: Dyn. Curved Front., 1966, pp. 363–76.

J. Hötzer, M. Jainta, P. Steinmetz, B. Nestler, A. Dennstedt, A. Genau, M. Bauer, H. Köstler, and U. Rüde: Acta Mater., 2015, vol. 93, pp. 194–204.

J. De Wilde, E. Nagels, F. Lemoisson, and L. Froyen: Mater. Sci. Eng. A., 2005, vol. 413–414, pp. 514–20.

P. Steinmetz, J. Hötzer, M. Kellner, A. Dennstedt, and B. Nestler: Comput. Mater. Sci., 2016, vol. 117, pp. 205–14.

A. Choudhury, Y.C. Yabansu, S.R. Kalidindi, and A. Dennstedt: Acta Mater., 2016, vol. 110, pp. 131–41.

P. Steinmetz, Y.C. Yabansu, J. Hötzer, M. Jainta, B. Nestler, and S.R. Kalidindi: Acta Mater., 2016, vol. 103, pp. 192–203.

Y.C. Yabansu, P. Steinmetz, J. Hötzer, S.R. Kalidindi, and B. Nestler: Acta Mater., 2017, vol. 124, pp. 182–94.

A. Dennstedt, L. Helfen, P. Steinmetz, B. Nestler, and L. Ratke: Metall. Mater. Trans. A., 2016, vol. 47A, pp. 981–84.

S. Mohagheghi, U. Hecht, S. Bottin-Rousseau, S. Akamatsu, G. Faivre, and M. Şerefoğlu: IOP Conf. Ser. Mater. Sci. Eng., 2019, vol. 529, p. 012010.

U. Hecht, J. Eiken, S. Akamatsu, and S. Bottin-Rousseau: Acta Mater., 2019, vol. 170, pp. 268–77.

S. Akamatsu, S. Bottin-Rousseau, M. Şerefoğlu, and G. Faivre: Acta Mater., 2012, vol. 60, pp. 3206–14.

H.J. Dai, N. D’Souza, and H.B. Dong: Metall. Mater. Trans. A., 2011, vol. 42A, pp. 3430–38.

H. Zhang and Q. Xu: Materials (Basel)., 2017, vol. 10, p. 1236.

T. Ferreira, M. Hiner, C. Rueden, K. Miura, J. Eglinger, and B. Chef: tferr/Scripts: BAR 1.5.1, April 2017. https://doi.org/10.5281/ZENODO.495245.

C.T. Rueden, J. Schindelin, M.C. Hiner, B.E. DeZonia, A.E. Walter, E.T. Arena, and K.W. Eliceriri: BMC Bioinform., 2017, vol. 18, pp. 1–26.

J. Schindelin, I. Arganda-Carreras, E. Frise, V. Kaynig, M. Longair, T. Pietzsch, S. Preibisch, C. Rueden, S. Saalfeld, B. Schmid, and J.Y. Tinevez: Nat. Methods., 2012, vol. 9, pp. 676–82.

F. Bachmann, R. Hielscher, and H. Schaeben: Solid State Phenom., 2010, vol. 160, pp. 63–68.

K. Kolatschek, M. Ellner, and B. Predel: J. Less Common Met., 1991, vol. 170, pp. 171–84.

A. Meetsma, J.L. de Boer, and S. Smaalen: J. Solid State Chem., 1989, vol. 83, pp. 370–72.

S. Grazulis, D. Chateigner, R.T. Downs, A.F.T. Yokochi, M. Quiros, L. Lutterotti, E. Manakova, J. Butkus, P. Moeck, and A. Le Bail: J. Appl. Crystallogr., 2009, vol. 42, pp. 726–29.

X. Wang, D. Wang, H. Zhang, Z. Tian, K. Du, J. Wang, L. Lou, and J. Zhang: Scripta Mater., 2016, vol. 116, pp. 44–48.

C. Yang, J. Gao, Y.K. Zhang, M. Kolbe, and D.M. Herlach: Acta Mater., 2011, vol. 59, pp. 3915–26.

Acknowledgments

The results in this work are the outcome of a collaboration of different research groups as part of the Project ‘Solidification along a Eutectic path in Ternary Alloys’ (SETA). The authors acknowledge funding from the National Aeronautics and Space Administration (NASA) under Grant Number NNX14AP82G within the Microgravity Research Program. Early EBSD on samples was carried out by Chad Parish at Oak Ridge National Laboratory through the ShaRE User Facility. The authors thank Samuel T. Small for polarized light microscopy investigations and post-processing of the EBSD data.

Conflict of interest

The authors declare that they have no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted August 3, 2021; accepted December 23, 2021.

Rights and permissions

About this article

Cite this article

Friess, J., Rayling, P., Hecht, U. et al. Microstructure Evolution and Grain Growth Competition in Directionally Solidified Ternary Al–Ag2Al–Al2Cu Eutectic. Metall Mater Trans A 53, 1294–1307 (2022). https://doi.org/10.1007/s11661-022-06590-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-022-06590-9