Abstract

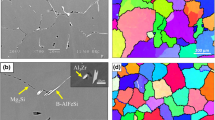

The recrystallization behaviors of deformed 6xxx aluminum alloys can be effectively controlled with α-Al(Mn,Cr)Si dispersoids by pinning or slowing the movement of dislocations. However, abnormal grain growth still often occurs due to the nonuniform distribution of α-Al(Mn,Cr)Si dispersoids. In the present study, the uniformity of dispersoids was significantly improved by applying two-step homogenization heat treatments. The effect of different homogenization conditions on the distribution of the α-Al(Mn,Cr)Si dispersoid was evaluated. By applying traditional one-step homogenization at 550 °C for 10 hours, the dispersoids exhibited sparse and nonuniform precipitation at the center of grains or dendritic arms. These areas with a nonuniform distribution of dispersoids were regarded as coarse dispersoid zones (CDZs). Relative to one-step homogenization, two-step homogenization led to a considerable reduction in the percentage of CDZ area from approximately 7 pct to less than 2.5 pct. This result was due to the diffusion of solute elements and the precipitation of metastable Mg2Si and Q phases because of isothermal holding during the first step. Metastable Mg2Si and Q phases could act as nucleation sites to promote the precipitation of α-Al(Mn,Cr)Si dispersoids. As a result, α-Al(Mn,Cr)Si dispersoids exhibited uniform precipitation, and the formation of CDZs was avoided. Two-step homogenization also improved the recrystallization resistance of the alloy because of the decrease in the percentage of CDZ area.

Similar content being viewed by others

References

W. H. Van Geertruyden, H. M. Browne, W. Z. Misiolek, P. T. Wang: Metallurgical and Materials Transactions A, 2005, vol. 36, pp. 1049-1056.

A. R. Eivani, J. Zhou, J. Duszczyk: Philosophical Magazine, 2016, vol. 96, pp. 1188-1196.

Y. Xu, H. Nagaumi, Y. Han, G. Zhang, T. Zhai: Metallurgical and Materials Transactions A, 2017, vol. 48, pp. 1355-1365.

K. Huang, K. Zhang, K. Marthinsen, R. E. Logé: Acta Materialia, 2017, vol. 141, pp. 360-373.

S. Tangen, K. Sjølstad, T. Furu, E. Nes: Metallurgical and Materials Transactions A, 2010, vol. 41, pp. 2970-2983.

K. Liu, X. G. Chen: Materials & Design, 2015, vol. 84, pp. 340-350.

Y. J. Li, L. Arnberg: Acta Materialia, 2003, vol. 51, pp. 3415-3428.

K. Liu, H. Ma, X. G. Chen: Journal of Alloys and Compounds, 2017, vol. 694, pp. 354-365.

Z. Li, Z. Zhang, X. G. Chen: Materials Science and Engineering: A, 2018, vol. 729, pp. 196-207.

A. M. F. Muggerud, E. A. Mørtsell, Y. Li, R. Holmestad: Materials Science and Engineering: A, 2013, vol. 567, pp. 21-28.

Z. Li, Z. Zhang, X.-G. Chen: Metals, 2018, vol. 8, p. 155.

Z. Li, Z. Zhang, X. G. Chen: Materials Science and Engineering: A, 2017, vol. 708, pp. 383-394.

H. Hirasawa: Scripta Metallurgica, 1975, vol. 9, pp. 955-958.

L. Lodgaard, N. Ryum: Materials Science and Engineering: A, 2000, vol. 283, pp. 144-152.

Z. Li, Z. Zhang, X. G. Chen: Metallurgical and Materials Transactions A, 2018, vol. 49, pp. 5799-5814.

C. L. Liu, Q. Du, N. C. Parson, W. J. Poole: Scripta Materialia, 2018, vol. 152, pp. 59-63.

Q. Du, W. J. Poole, M. A. Wells, N. C. Parson: Acta Materialia, 2013, vol. 61, pp. 4961-4973.

Y. Birol: Journal of Materials Processing Technology, 2004, vol. 148, pp. 250-258.

N. C. W. Kuijpers, J. Tirel, D. N. Hanlon, S. van der Zwaag: Materials Characterization, 2002, vol. 48, pp. 379-392.

S. Kumar, P. S. Grant, K. A. Q. O’Reilly: Metallurgical and Materials Transactions A, 2016, vol. 47, pp. 3000-3014.

N. Bayat, T. Carlberg, M. Cieslar: Journal of Physics and Chemistry of Solids, 2019, vol. 130, pp. 165-171.

N. Bayat, T. Carlberg, M. Cieslar: Journal of Alloys and Compounds, 2017, vol. 725, pp. 504-509.

H. Tanihata, T. Sugawara, K. Matsuda, S. Ikeno: Journal of Materials Science, 1999, vol. 34, pp. 1205-1210.

M. S. Remøe, I. Westermann, K. Marthinsen: Metals, 2018, vol. 9, p. 26.

Y. J. Li, A. M. F. Muggerud, A. Olsen, T. Furu: Acta Materialia, 2012, vol. 60, pp. 1004-1014.

F. Qian, S. Jin, G. Sha, Y. Li: Acta Materialia, 2018, vol. 157, pp. 114-125.

Q. Yang, Z. Deng, Z. Zhang, Q. Liu, Z. Jia, G. Huang: Materials Science and Engineering: A, 2016, vol. 662, pp. 204-213.

R. Smith: Metallurgical and Materials Transactions B, 2018, vol. 49, pp. 3258-3279.

K. E. Knipling, D. C. Dunand, D. N. Seidman: Zeitschrift für Metallkunde, 2006, vol. 97, pp. 246-265.

M. Patrick Dugan, T. Tsakalakos: Superlattices and Microstructures, 1988, vol. 4, pp. 565-570.

S.-i. Fujikawa, K.-i. Hirano, Y. Fukushima: Metallurgical Transactions A, 1978, vol. 9, pp. 1811-1815.

Acknowledgments

The authors acknowledge the financial support provided by Shandong Weiqiao Pioneering Group Co., Ltd., National Natural Science Foundation of China (Grant No. U1864209) and China Postdoctoral Foundation Grant (Grant No. 2018M642309).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted October 22, 2019; accepted March 10, 2021.

Rights and permissions

About this article

Cite this article

Li, Z., Qin, J., Zhang, H. et al. Improved Distribution and Uniformity of α-Al(Mn,Cr)Si Dispersoids in Al-Mg-Si-Cu-Mn (6xxx) Alloys by Two-Step Homogenization. Metall Mater Trans A 52, 3204–3220 (2021). https://doi.org/10.1007/s11661-021-06243-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-021-06243-3