Abstract

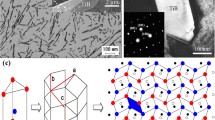

Deformation twins play a significant role in the plastic deformation of titanium matrix composites and improve their ductility. In this work, \( \left\{ {10\bar{1}2} \right\} \) deformation twins nucleated in the parent grains with a hard orientation of prismatic slip and changed the local orientation become a soft orientation, resulting in a good balance between high strength (yield strength of 1068 ± 9 MPa and ultimate tensile strength of 1167 ± 1MPa) and high ductility (elongation of 8.7 ± 0.2 pct) at room temperature for hybrid TiB-TiC reinforced Ti-6Al-4V matrix composites. TiB, TiC and grain boundaries worked as a barrier to dislocation mobility, and resulted in different dislocation substructures distributing around the short TiB fibers and TiC particles. The strain incompatibility resulted in a high local stress concentration which promoted twin nucleation and influenced twin propagation. The nonuniform strain caused a stress gradient inside the grains, and the steep stress gradient hindered the twin propagation. Low stress was not enough to drive the dislocation slip of the twins and dislocation decomposition at the twin tips; thus, the growth of the deformation twins stopped in the parent grains.

Similar content being viewed by others

References

[1] P. Qiu, Y. Han, G. Huang, J. Le, L. Lei, L. Xiao and W. Lu: Metall. Mater. Trans. A, 2020, vol. 51, pp. 2276-2290.

[2] V.A. Popov, E.V. Shelekhov, A.S. Prosviryakov, M.Y. Presniaov, B.R. Senatulin, A.D. Kotov and M.G. Khomutov: J. Alloys Compd., 2016, vol.707, pp. 365-370.

[3] J. Li, L. Wang, J. Qin, Y. Chen, W. Lu and D. Zhang: Mater. Charact, 2012, vol. 66, pp. 93-98.

[4] L.C. Zhang and H. Attar: Adv. Eng. Mater, 2016, vol. 18, pp. 463-475.

[5] M. D. Hayat, H. Singh, Z. He and P. Cao: Composites Part A, 2019, vol. 121, pp. 418-438.

[6] J. Le, Y. Han, J. Xiang, L. Lei, G. Huang and W. Lu: Metall. Mater. Trans. A, 2020, vol. 51, pp. 1732-1743.

[7] J. Yang, Y. Chen, S. Xiao, L. Xu, X. Wang, J. Tian, D. Zhang and Z. Zheng: Mater. Sci. Eng. A, 2020, vol. 788, pp. 1-10.

[8] H.K.S. Rahoma, Y.Y. Chen, X.P. Wang and S.L. Xiao: J. Alloys Compd., 2015, vol. 627, pp. 415-422.

[9] S. Li, K. Kondon, H. Imail, B. Chen, L. Jia, J. Umeda and Y. Fu: Mater. Des., 2016, vol. 95, pp. 127-132.

[10] S. Li, K. Kondoh, H. Imai, B. Chen, L. Jia and J. Umeda: Mater. Sci. Eng. A, 2015, vol. 628, pp. 75-83.

[11] Z Y. Hu, X.W. Cheng, S.L. Li, H.M. Zhang, H. Wang, Z.H. Zhang and F.C. Wang: J. Alloys Compd., 2017, vol. 726, pp. 240-253.

[12] X. Guo, L. Wang, M. Wang, J. Qin, D. Zhang and W. Lu: Acta Mater., 2012, vol. 60, pp. 2656-2667.

[13] P. Zhou, J. N. Qin, W. J. Lu and D. Zhang: Mater. Sci. Technol., 2011, vol. 27, pp. 1788-1792.

[14] G. Huang, X. Guo, Y. Han, L. Wang, W. Lu and D. Zhang: Mater. Sci. Eng. A, 2016, vol. 667, pp. 317-325.

[15] J. Wang, X. Guo, J. Qin, D. Zhang and W. Lu: Mater. Sci. Eng. A, 2015, vol. 628, pp. 366-373.

L.J. Lu, L. Geng and H. X. Peng: Mater. Sci. Eng. A 2010, 527, 6723-6727.

[17] Z.W. Huang, P.L. Yong, N.N. Liang, and Y.S. Li: Mater, Charact, 2019, vol. 149, pp. 52-62.

[18] N.P. Gurao, R. Kapoor and S. Suwas: Acta Mater., 2011, vol. 59, pp. 3431-3446.

[19] W. Tirry, M. Nixon, O. Cazacu, F. Coghe and L. Rabet: Scr. Mater., 2011, vol. 64, pp. 840-843.

[20] S. Xu, P. Zhou, G. Liu, D. Xiao, M. Gong and J. Wang: Acta Mater., 2019, vol. 165, 547-560.

[21] S. Liu, H. Ding, H. Zhang, R. Chen, J. Guo and H. Fu: Nanoscale, 2018, vol. 10, pp. 11365-11374.

[22] R. Kalsar and S. Suwas: Scr. Mater., 2018, vol. 154, pp. 207-211.

[23] S. Xu, M. Gong, Y. Jiang, C. Schuman, J.S. Lemote and J. Wang: Acta Mater., 2018, vol. 152, pp. 58-76.

[24] I.J. Beyerlein, L. Capolungo, P.E. Marshall, R.J. McCabe and C.N. Tome: Philos. Mag. A, 2010, vol. 90, pp. 2161-2190.

[25] C.M. Cepeda-Jiménez, J.M. Molina-Aldareguia and M.T. Pérez-Prado: Acta Mater. 2015, vol. 88, pp. 232-244.

[26] A. Ghaderi and M.R. Barnett: Acta Mater., 2011, vol. 59, pp. 7824-7839.

C.M. Cepeda-Jimenez, J.M. Molina-Aldareguia and M.T. Perez-Prado: Acta Mater., 2015, 88, 232-244.

[28] T. Hama, T. Suzuki, S. Hatakeyama, H. Fujimoto and H. Takuda: Mater. Sci. Eng. A, 2018, vol. 725, pp. 8-18.

H. E. Kadiri, J. Kapil, A.L. Oppedal, L.G. Hector, S.R. Agnew, M. Cherka, S.C. Vogel: Acta Mater., 2013, 61, 3549-3563.

A.J. WagonerJohnson, C.W. Bull, K.S. Kumar and C.L. Briant: Metall. Mater. Trans. A, 2003, vol. 34, pp. 295-306.

[31] X. Zheng, S. Zheng, J. Wang, Y. Ma, H. Wang, Y. Zhou, X. Shao, B. Zhang, J. Lei, R. Yang and X. Ma: Acta Mater., 2019, vol. 181, pp. 479-490.

[32] T. Braisaz, P. Ruterana and G. Nouet: Philos. Mag. A, 1997, vol. 76, pp. 63-84.

[33] Johnson A J W, Kumar K S and Briant C L: Metall. Mater. Trans. A, 2003, vol. 34, pp. 1869-1877.

W. Gerhard, R.R. Boyer and E.W. Collings: Material Properties Handbook Titanium Alloys. ASM International, Cleveland; 1994

[35] Y. Guo, T.B. Britton and A.J. Wilkinson: Acta Mater., 2014, vol. 76, pp. 1-12.

H. Li, D. E. Mason, T. R. Bieler, C.J. Boehlert and M.A. Crimp: Acta Mater., 2013, 61:7555-7567.

[37] I.P. Jones and W.B. Hutchinson: Acta Metall. 1981; 29: 951-968.

[38] D. Hill, R. Banerjee, D. Huber, J. Tiley and H.L. Fraser: Scr. Mater., 2005, vol. 52, pp. 387-392.

[39] D.X. Li, D.H. Ping, Y.X. Lu and H.Q. Ye: Mater. Lett., 1993, vol. 16, pp. 322-326.

[40] E. Zhang, S. Zeng. and Z. Zhu: J. Mater. Sci., 2000, vol. 35, pp. 5989-5994.

[41] T. T. Sasaki, B. Fu and K. Torres: Philosophical Magazine, 2011, vol. 6, pp. 850-864.

[42] S. Roy and S. Suwas: Acta Mater., 2017, vol. 134, pp. 283-301.

[43] H. Li, D.E. Mason, T.R. Bieler, C.J. Boehlert and M.A. Crimp: Acta Mater., 2013, vol. 61, pp.7555-7567.

G. Lutjering and J. Williams: Introduction Titanium. Springer, Berlin 2007.

[45] Y. Mine, S. Katashima, R. Ding, P. Bowen and K. Takashima: Scr. Mater., 2019, vol. 165, pp. 107-111.

[46] M.A. Meyers, O. Vöhringer and V.A. Lubarda: Acta Mater. 2001, vol. 49, pp. 4025-4039.

[47] L. Capolungo, P.E. Marshall, R.J. Mccabe, I.J. Beyerlein and C.N. Tome: Acta Mater., 2009, vol. 57, pp. 6047-6056.

[48] V.C. Nardone and K.M. Prewo: Scr. Metall., 1986, vol. 20, pp. 43-48.

[49] N. Ramakrishnan: Acta Mater., 1996, vol. 44, pp. 69-77.

[50] P. Paupler and G. E. Dieter: Mechanical Metallurgy, third ed., Mc Graw-Hill Book Co., New York, 1986.

[51] M.A. Meyers and K.K. Chawla: Mechanical Behaviour of Materials, Prentice-Hall, Saddle River, 1999.

[52] M. Taya and R.J. Arsenault: Metal matrix composites—thermomechanical behavior, Pergamon Press, New York, 1989.

[53] L.M. Brown and W.M. Stobbs: Philos. Mag. 1976, vol. 34, pp. 351-372.

[54] N. Bosh, C. Müllera and H. Mozaffari-Jovein: Mater. Charact., 2019, vol. 155, pp. 109810.

[55] T.L. Anderson: Fracture mechanics: fundamentals and applications, CRC Press, Taylor & Francis, Boca Raton, 1991.

[56] Zhang R Y, Daymond M R and Holt R A: Mater. Sci. Eng. A, 2008, vol. 473, pp. 139-146.

[57] Zhang R Y, Daymond M R and Holt R A, Mater. Sci. Eng. A, 2011, vol. 528, pp. 2725-2735.

Acknowledgments

This work was supported by National Natural Science Foundation of China (Grant Nos: 51871150, U1602274, 51875349, 51821001); National Key Research and Development Program of China (Grant No. 2018YFB1106403); Shanghai Science and Technology Committee Innovation Grant (Grant Nos: 17JC1402600, 17DZ1120000); Major Special Science and Technology Project of Yunnan Province (Grant No. 2018ZE002); the Equipment Pre-Research Foundation (Grant Nos. 41422010509, 61409230409); the 111 Project (Grant No. B16032); the Laboratory Innovative Research Program of Shanghai Jiao Tong University (Grant No. 17SJ-14) and the financial support from China Scholarship Council (CSC) (Grant No 201806235029).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted June 22, 2020 and accepted September 27, 2020.

Rights and permissions

About this article

Cite this article

Wang, X., Han, Y., Su, X. et al. The Formation of \( \left\{ {10\bar{1}2} \right\} \) Deformation Twin in Hybrid TiB-TiC Reinforced Titanium Matrix Composites. Metall Mater Trans A 52, 350–363 (2021). https://doi.org/10.1007/s11661-020-06067-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-020-06067-7