Abstract

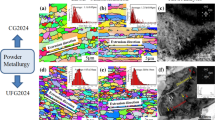

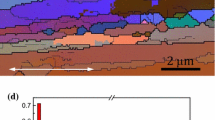

In this study, ultrafine-grained W alloys with various amount of La2O3 addition (0.5 ~ 5.0 wt pct) have been prepared by pressureless sintering. The influence of the addition of La2O3 particles on the grain growth of ultrafine-grained W alloys have been studied. The results showed that the addition of La2O3 particles can significantly decrease the grain growth rate, but it seems counterintuitive that the ultrafine-grained W alloy with 2.0 wt pct La2O3 addition, rather than 5.0 wt pct, has the smallest grain size (1.23 μm) after annealing at 1900 °C for 6 h. To reveal the abnormal grain growth behavior, the inhibition effect of the size and distribution of La2O3 particles on grain growth was analyzed, suggesting that the excessive addition of La2O3 particles can cause an abnormal increase in grain size duo to the large fraction of intergranular particles, the small-particle spacing and the high mass transfer rate at the grain boundary.

Similar content being viewed by others

Reference

1. F. Ferroni, X. Yi, K. Arakawa, S. P. Fitzgerald, P. D. Edmondson and S. G. Roberts, Acta Mater. 2015, vol. 90, pp. 380-393.

2. L. Huang, L. Jiang, T. D. Topping, C. Dai, X. Wang, R. Carpenter, C. Haines and J. M. Schoenung, Acta Mater. 2017, vol. 122, pp. 19-31.

3. S. Antusch, D. E. J. Armstrong, T. B. Britton, L. Commin, J. S. K. L. Gibson, H. Greuner, J. Hoffmann, W. Knabl, G. Pintsuk, M. Rieth, S. G. Roberts and T. Weingaertner, Nucl. Mater. Energy 2015, vol. 3-4, pp. 22-31.

4. Z. S. Levin and K. T. Hartwig, Mater. Sci. Eng. A 2017, vol. 707, pp. 602-611.

5. Z. M. Xie, R. Liu, S. Miao, X. D. Yang, T. Zhang, X. P. Wang, Q. F. Fang, C. S. Liu, G. N. Luo, Y. Y. Lian and X. Liu, Sci. Rep. 2015, vol. 5, p. 16014.

6. C. Ren, Z. Z. Fang, L. Xu, J. P. Ligda, J. D. Paramore and B. G. Butler, Acta Mater. 2019, vol. 162, pp. 202-213.

7. X. Tan, L. Luo, H. Chen, X. Zhu, X. Zan, G. Luo, J. Chen, P. Li, J. Cheng, D. Liu and Y. Wu, Sci. Rep. 2015, vol. 5, p. 12755.

8. Z. M. Xie, S. Miao, R. Liu, L. F. Zeng, T. Zhang, Q. F. Fang, C. S. Liu, X. P. Wang, Y. Y. Lian, X. Liu and L. H. Cai, J. Nucl. Mater. 2017, vol. 496, pp. 41-53.

9. S. Bonk, J. Reiser, J. Hoffmann and A. Hoffmann, Int. J. Refract. Met. Hard Mater. 2016, vol. 60, pp. 92-98.

10. M. Battabyal, R. Schäublin, P. Spätig, M. Walter, M. Rieth and N. Baluc, J. Nucl. Mater. 2013, vol. 442, pp. S225-S228.

11. Y. Wang and J. Aktaa, Scr. Mater. 2017, vol. 139, pp. 22-25.

12. Y. Wang and J. Aktaa, Materialia 2018, vol. 2, pp. 46-52.

13. J. Echigoya, M. Taya and WD Armstrong, Mater. Sci. Eng. A 1991, vol. 141, pp. 63-66.

14. A. Luo, K. S. Shin and D. L. Jacobson, Mater. Sci. Eng. A 1991, vol. 148, pp. 219-229.

15. M. Xia, Q. Yan, L. Xu, H. Guo, L. Zhu and C. Ge, J. Nucl. Mater. 2013, vol. 434, pp. 85-89.

16. J. Li, J. Cheng, B. Wei, M. Zhang, L. Luo and Y. Wu, Int. J. Refract. Met. Hard Mater. 2017, vol. 66, pp. 226-233.

17. R. Liu, Z. M. Xie, T. Zhang, Q. F. Fang, X. P. Wang, T. Hao, C. S. Liu and Y. Dai, Mater. Sci. Eng. A 2016, vol. 660, pp. 19-23.

Z. Dong, N. Liu, Z. Ma, C. Liu, Q. Guo, Z. A. Alothman, Y. Yamauchi, A. Hossain, M. Shahriar and Y. Liu, Sci. Rep. 2017, vol. 7, p. 6051.

19. Z. Dong, N. Liu, Z. Ma, C. Liu, Q. Guo and Y. Liu, J. Alloys Compd. 2017, vol. 695, pp. 2969-2973.

20. Y. Lv, J. Fan, Y. Han, T. Liu, P. Li and H. Yan, J. Alloys Compd. 2019, vol. 774, pp. 1140-1150.

21. Z. Dong, N. Liu, W. Hu, Z. Ma, C. Li, C. Liu, Q. Guo and Y. Liu, J. Mater. Sci. Technol. 2020, vol. 36, pp. 118-127.

22. W. Hu, Z. Dong, L. Yu, Z. Ma and Y. Liu, J. Mater. Sci. Technol. 2020, vol. 36, pp. 84-90.

N. Liu, Z. Dong, Z. Ma, Z. Qian, L. Ma, L. Yu and Y. Liu, Acta Metall. Sin. 2020, 1, pp. 1-6.

24. R. Liu, X. P. Wang, T. Hao, C. S. Liu and Q. F. Fang, J. Nucl. Mater. 2014, vol. 450, pp. 69-74.

S. Miao, Z. M. Xie, L. F. Zeng, T. Zhang, Q. F. Fang, X. P. Wang, C. S. Liu, G. N. Luo and X. Liu, Fusion Eng. Des. 2017. 16: 191-206

26. Y. K. Wang, S. Miao, Z. M. Xie, R. Liu, T. Zhang, Q. F. Fang, T. Hao, X. P. Wang, C. S. Liu, X. Liu and L. H. Cai, J. Nucl. Mater. 2017, vol. 492, pp. 260-268.

27. M. Qin, Z. Chen, P. Chen, S. Zhao, R. Li, J. Ma and X. Qu, Int. J. Refract. Met. Hard Mater. 2017, vol. 68, pp. 145-150.

28. M. Qin, J. Yang, Z. Chen, P. Chen, S. Zhao, J. Cheng, P. Cao, B. Jia, G. Chen, L. Zhang and X. Qu, Mater. Sci. Eng. A 2020, vol. 774, pp. 138878.

29. J. Fan, Y. Han, P. Li, Z. Sun and Q. Zhou, J. Nucl. Mater. 2014, vol. 455, pp. 717-723.

30. Z. Z. Fang and H. Wang, Int. Mater. Rev. 2008, vol. 53, pp. 326-352.

31. O. B. Bembalge and S. K. Panigrahi, Metall. Mater. Trans. A 2019, vol. 50, pp. 4288-4306.

32. H. Wang, Z. Z. Fang and K. S. Hwang, Metall. Mater. Trans. A 2011, vol. 42, pp. 3534-3542.

33. W. H. Liu, Y. Wu, J. Y. He, T. G. Nieh and Z. P. Lu, Scr. Mater. 2013, vol. 68, pp. 526-529.

W. Ni, C. G. Schmidt, F. Teocoli, A. Kaiser, K. B. Andersen, S. Ramousse and V. Esposito, J. Eur. Ceram. Soc. 2013, vol. 33, pp. 2529-2537.

35. N. Nafsin, J. A. Aguiar, T. Aoki, A. M. Thron, K. van Benthem and R. H. R. Castro, Acta Mater. 2017, vol. 136, pp. 224-234.

36. W. Ni, K. B. Andersen and V. Esposito, J. Eur. Ceram. Soc. 2014, vol. 34, pp. 3769-3778.

37. T. Frolov, Q. Zhu, T. Oppelstrup, J. Marian and R. E. Rudd, Acta Mater. 2018, vol. 159, pp. 123-134.

38. G. Gottstein and L.S. Shvindlerman, Acta Metall. Mater. 1993, vol. 41, pp. 3267-3275.

39. L. Jiang, H. Wen, H. Yang, T. Hu, T. Topping, D. Zhang, E. J. Lavernia and J. M. Schoenung, Acta Mater. 2015, vol. 89, pp. 327-343.

Acknowledgments

This work is financially supported by the National Key R&D Program of China (2017YFB0306000 and 2017YFB0305600), the National Natural Science Foundation Program of China (51574031, 51604239, 51604240 and 51674095), the Natural Science Foundation Program of Beijing (2162027), the General Project of the Education Department of Hunan Province (15C1308), and the Fundamental Research Funds for the Central Universities (JZ2017HGBZ0920).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted December 10, 2019.

Rights and permissions

About this article

Cite this article

Chen, Z., Qin, M., Yang, J. et al. Thermal Stability and Grain Growth Kinetics of Ultrafine-Grained W with Various Amount of La2O3 Addition. Metall Mater Trans A 51, 4113–4122 (2020). https://doi.org/10.1007/s11661-020-05836-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-020-05836-8